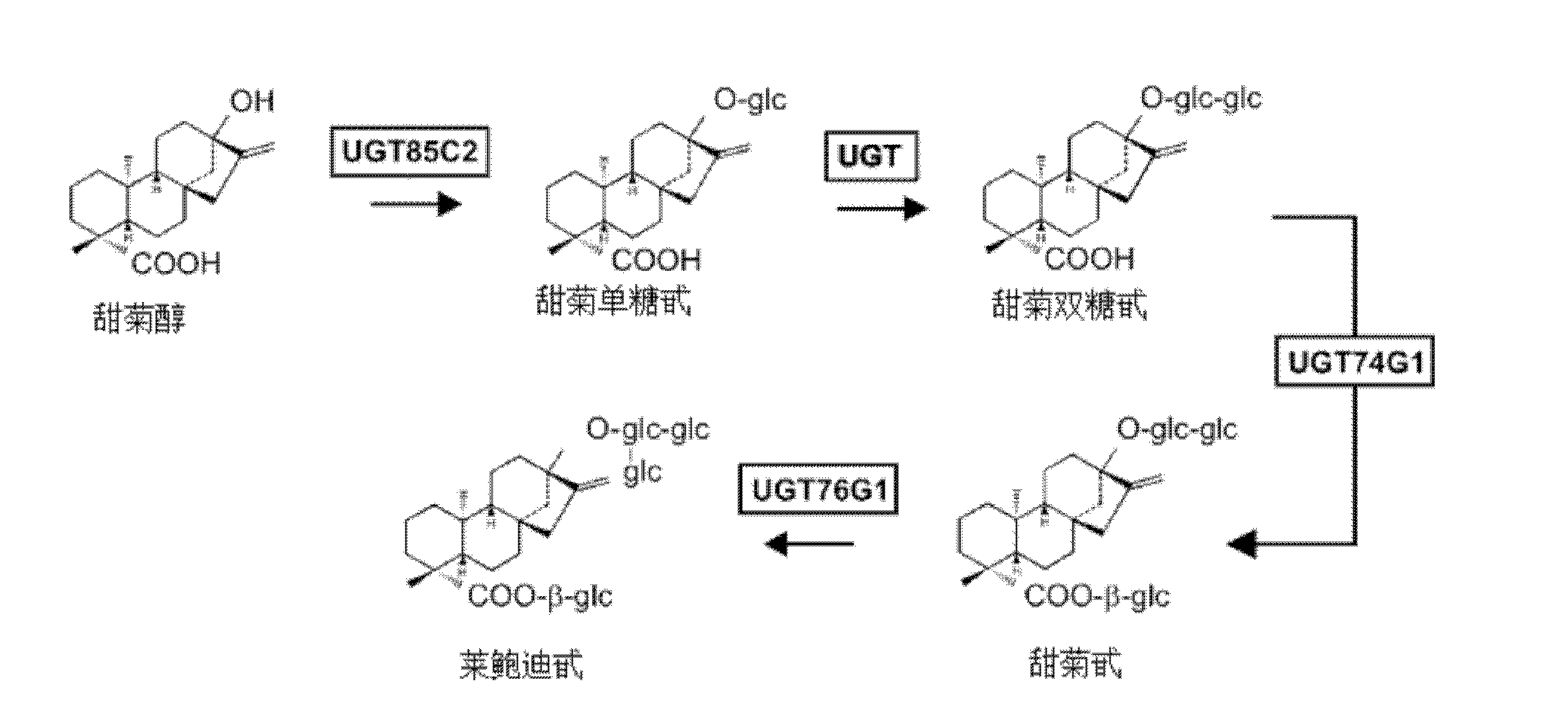

Genetically engineered bacteria used for producing stevia glycosyltransferase UGT76G1 and application thereof

A technology of UGT76G1, genetically engineered bacteria, applied in genetic engineering, transferase, application, etc., can solve the problems of not being a solution, high price, difficult purification process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

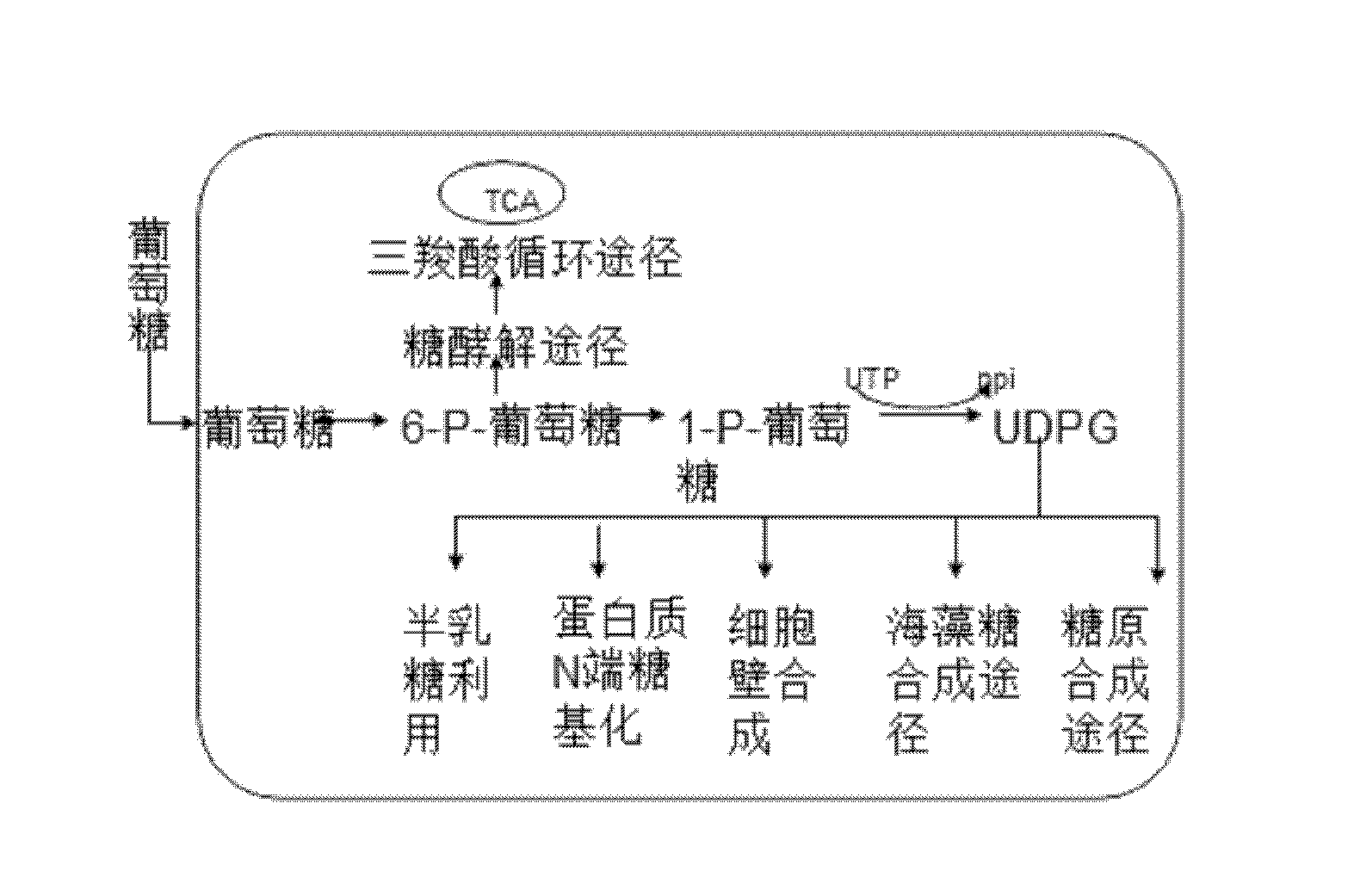

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Construction of recombinant yeast.

[0051] 1. Acquisition of glycosyltransferase UGT gene:

[0052] According to the AY345974.1 gene sequence, codon optimization was carried out, and the optimized gene sequence was named UGT, and the gene synthesis was completed by Nanjing Jinsirui Company.

[0053] Design primers based on UGT gene sequence

[0054] The upstream primer (-sense contains EcoRI) is:

[0055] 5′-CGGAATTCAAACAATGTCTGAAAATAAGACTGAAACTACTG-3′

[0056] The downstream primer (-sense contains XhoI) is:

[0057] 5′-CCGCTCGAGTTATAATGATGAAATATAAGAAACCAA-3′

[0058] All primers were synthesized by Shanghai Shenergy Gaming Company.

[0059] Gene PCR conditions (50μL system):

[0060] Denaturation at 94°C for 5 minutes;

[0061] Cycle 30 times according to the following parameters: denaturation at 94°C for 30 s, annealing at 60°C for 30 s, extension at 72°C for 2 min;

[0062] Finally, extend at 72°C for 10 min.

[0063] 2. The recombinant engineered...

Embodiment 2

[0069] Example 2: Induced expression of recombinant yeast.

[0070] Pick a single colony of the recombinant engineered bacteria into SC-U medium, and cultivate overnight at 30°C with shaking. Then inoculate on the fresh medium whose carbon source is glucose (final concentration is 20g / L) according to 2% inoculation amount, cultivate 8h, this part is the accumulation of biomass. Then in a sterile environment, collect the bacteria and discard the supernatant, wash the bacteria and transfer the bacteria to a fresh selection medium whose carbon source is galactose (final concentration is 20g / L) for induction. The induction time is 48h. The bacterial solution was centrifuged at 6000 rpm at 4°C for 10 min, and the supernatant was discarded.

[0071] Among them, the medium formula with glucose as the carbon source is: 6.7g / L YNB, 20g / L glucose, 0.1g / L adenine, 0.1g / L arginine, 0.1g / L cysteine, 0.1g / L L Leucine, 0.1g / L Lysine, 0.1g / L Threonine, 0.1g / L Tryptophan, 0.05g / L Aspartic A...

Embodiment 3

[0073] Example 3: Establishment of enzyme activity assay method.

[0074] Get the thalline precipitation in Example 2, thalline 20mg, wash twice with potassium phosphate buffer (pH7.0), the precipitation after washing is ground and broken in liquid nitrogen, and wash with potassium phosphate buffer (pH7.0) The broken bacterial solution was centrifuged at 12000rpm and 4°C for 15min. The supernatant is the crude enzyme solution. Precisely weigh the sample and prepare a 1.4ml system, in which the final concentration of stevioside is 1g / L, UDP-glucose is 1g / L, and 2g / L Mgcl is added 2 ; Mix 10mg / L BSA, and finally add 400μl of crude enzyme solution and potassium phosphate buffer (pH7.0) until the system is 1.4ml, and start the reaction. After heat preservation at 30°C for 12h, the reaction was terminated by boiling at high temperature. Centrifuge and take the supernatant as a sample. The content of rebaudiosideA glycoside in the reaction system was detected by HPLC. The exper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com