SnO2-Fe2O3NTs (SnO2-Fe2O3 nanotubes) composite electrode and preparation method thereof

A composite technology of ferric oxide and nanotubes, which is applied in electrochemical water/sewage treatment, magnetic field/electric field water/sewage treatment, energy and wastewater treatment, etc., to achieve high order, good template effect, and efficient synergy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

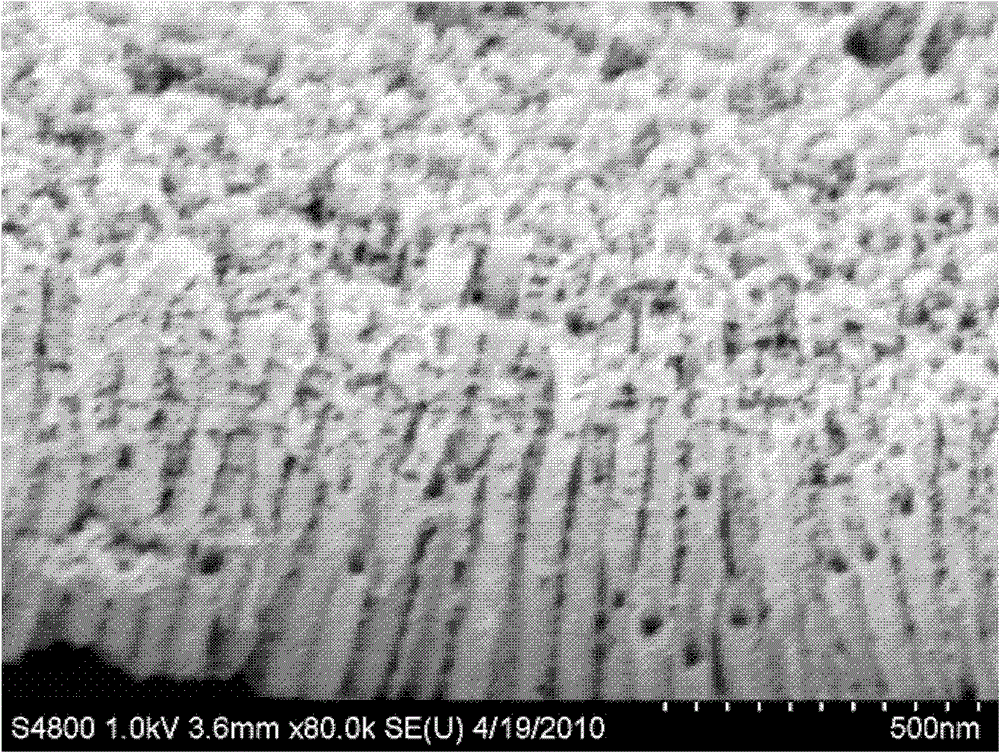

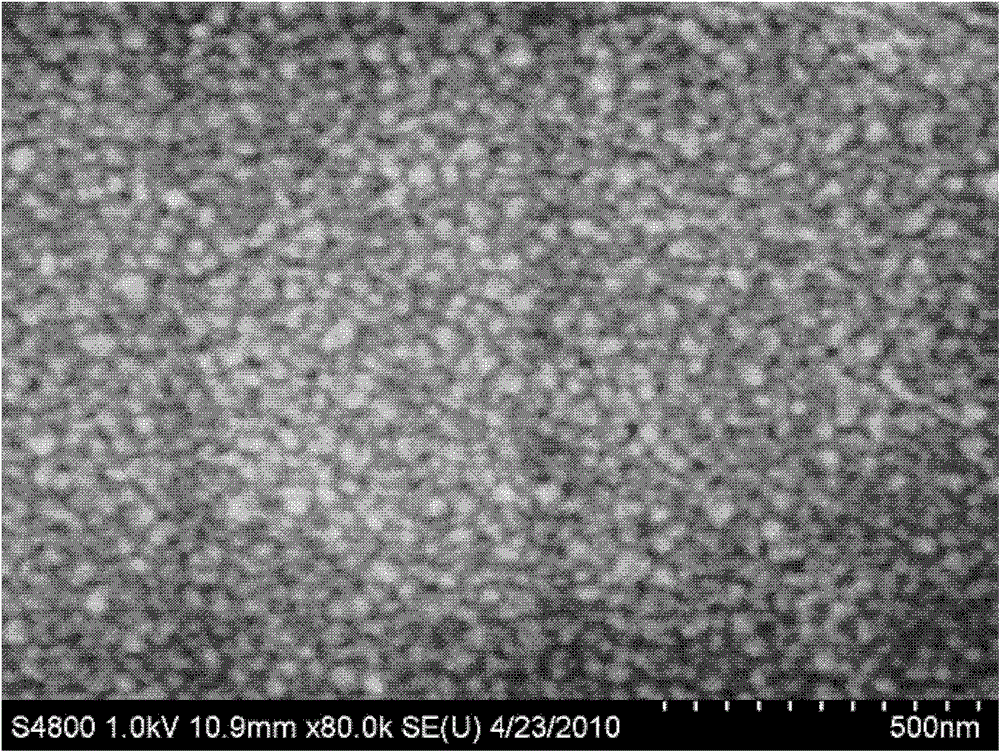

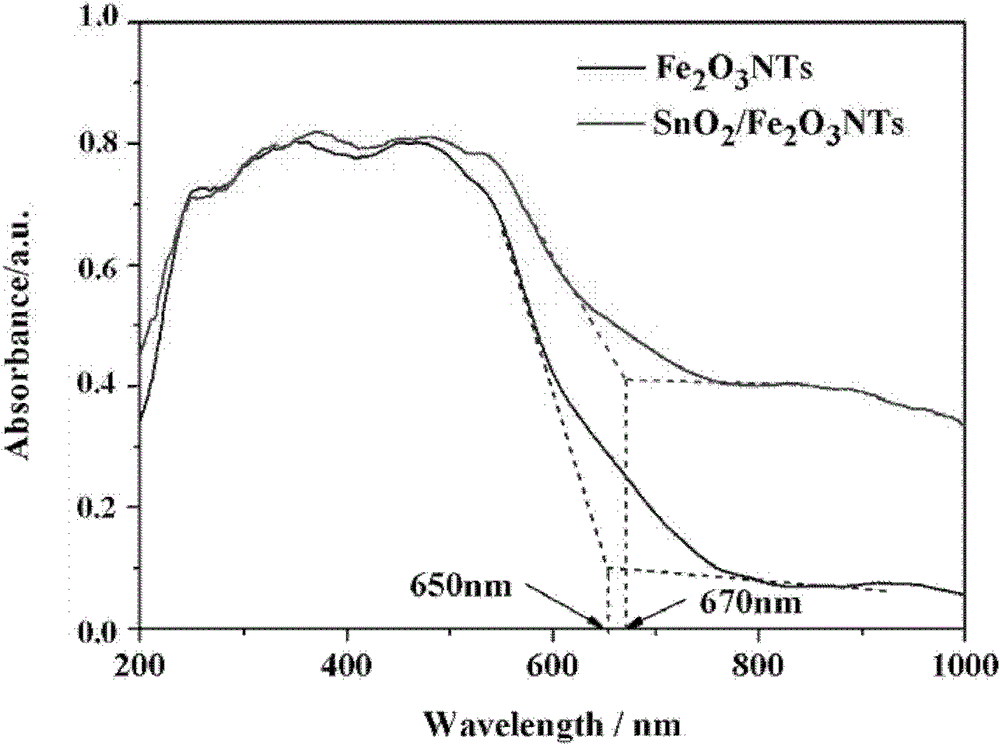

[0027] A tin dioxide-ferric oxide nanotube composite electrode and a preparation method thereof, specifically comprising the following steps:

[0028] (1) Use 0.25mm iron sheet (99.9%) with 120 # , 320 # and 500 # Grinding with sandpaper, further polishing with metallographic sandpaper to make the surface of the substrate smooth, then ultrasonically cleaning in distilled water and acetone for 20 min, and cleaning with double distilled water. The composition of the anodizing electrolyte is 0.3wt% NH 4 F, 3%H 2 O, in a mixed solution with ethylene glycol as a solvent, with an iron sheet as the working electrode and a platinum sheet as the counter electrode, the voltage across both ends was controlled to be constant at 20V, the reaction temperature was constant at 25°C, and the electrochemical anodic oxidation treatment was performed for 5min. The prepared electrodes were heat-treated in a tube furnace using temperature programming at a temperature of 5 °C min -1 , the heat ...

Embodiment 2

[0035] Using the tin dioxide-ferric oxide nanotube composite electrode prepared in Example 1, the visible photoelectrocatalytic oxidation degradation dye methylene blue (MB) simulated dye wastewater.

[0036] The photocatalytic degradation is carried out in a single-cell semicircular electrochemical reaction cell, and a cup with circulating water is added to keep the temperature of the reaction system at room temperature. The prepared electrode is used as the anode, the titanium sheet is used as the counter electrode, the electrode spacing is 1 cm, and the electrode area is 6 cm. 2 , to contain 0.1mol L -1 Na 2 SO 4 20mg L of electrolytes -1 MB solution was used as a simulated dye wastewater, the reaction volume was 100mL, and the degradation current density was 5mA cm -2 , the visible light source is a light energy density of 100mW / cm 2 Visible light irradiation (λ > 420nm), samples were taken at different times during the degradation reaction for analysis. The immediat...

Embodiment 3

[0038] Using the tin dioxide-ferric oxide nanotube composite electrode prepared in Example 1, it can be seen that photoelectric catalytic oxidation degrades 2,4,6-trichlorophenol (TCP) simulated wastewater that is difficult to biochemically oxidize.

[0039] The photocatalytic degradation is carried out in a single-cell semicircular electrochemical reaction cell, and a cup with circulating water is added to keep the temperature of the reaction system at room temperature. The prepared electrode is used as the anode, the titanium sheet is used as the counter electrode, the distance between the electrodes is 1 cm, and the electrode area is 8 cm. 2 , to contain 0.1mol L -1 Na 2 SO 4 100mg L of electrolyte -1 TCP solution was used as a simulated dye wastewater, the reaction volume was 100ml, and the degradation current density was 10mA cm -2 , the visible light source is a light energy density of 100mW / cm 2Visible light irradiation (> 420nm), samples were taken and analyzed at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance value | aaaaa | aaaaa |

| Impedance value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com