Preparation and application methods for novel magnetic molecular sieve adsorbent material

A magnetic and raw material technology, applied in the field of preparation of new magnetic molecular sieve adsorbent materials, can solve the problems of difficult separation, small processing capacity, difficult large-scale application, etc., and achieve the effect of stable quality, good adsorption performance, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] The preparation method of example 1, ferromanganese spinel: a certain amount of manganese chloride and ferric chloride are dissolved in the ultrapure water of 20mL deoxygenation, ultrasonic-assisted dissolution (Mn in the final solution 2+ and Fe 3+ molar ratio = 1:2). 250mL (1.5mol / L) of NaOH solution (N 2 deoxidation for 30min) slowly dropwise into the above mixture, and vigorously stirred (~400r / min), the reaction temperature is controlled at 30°C, the reaction time is 1~1.5h, and N 2 Protect. The obtained solution was added into a Teflon-lined autoclave for crystallization at 100° C. for 3 h. After the reaction is completed, the magnetic material is separated under the action of an external magnetic field, washed with pure water and ethanol for 4 to 5 times, and vacuum-dried at 60° C. for 2 hours.

example 2

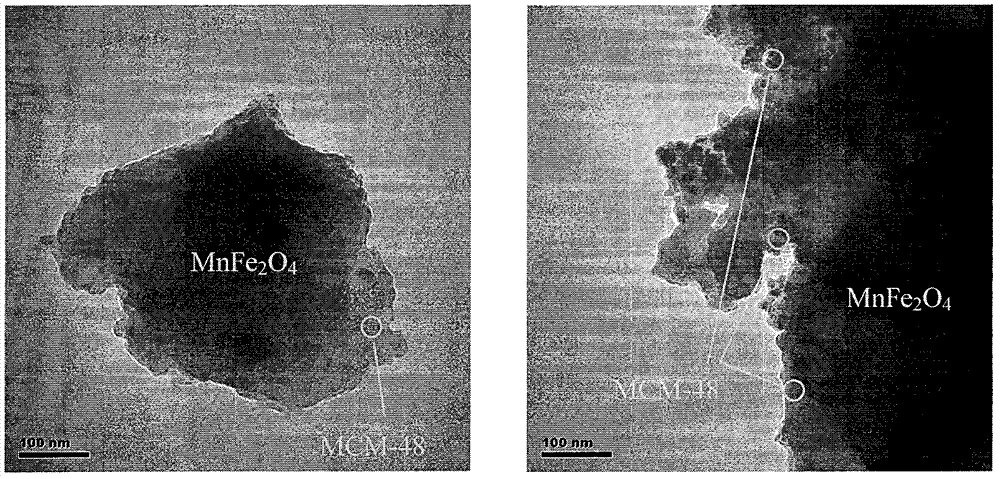

[0022] Example 2, the synthesis steps of molecular sieve-coated ferromanganese spinel method: 4.8g of cetyltrimethylammonium bromide is dissolved in 100g of ultrapure water, and 100mL of absolute ethanol and 34mL (28wt%) of ammonia are added. 0.005mol MnFe 2 o 4 After adding to the above solution, the mixture was vigorously stirred at 30° C. for 15 min with the aid of ultrasound. 6.8g of tetraethyl orthosilicate was slowly added dropwise to the above mixture, and vigorously stirred. After the dropwise addition was completed, the reaction was continued for 1.5h. The obtained solution was filtered by suction and washed with ultrapure water to pH ≈ 7. Vacuum-dried at 60°C for 4 hours, the dry glue was ground, heated to 400°C after 400 minutes, and calcined for 3 hours under nitrogen protection.

example 3

[0023] Example 3. Application of new magnetic molecular sieve adsorbent in water treatment: A certain oxytetracycline-containing wastewater, the concentration of oxytetracycline is 500μg / L, take 1L of wastewater, add 1g of new magnetic molecular sieve adsorbent, and stir under dark conditions Magnetic separation is performed after mixing for 2 hours, the concentration of oxytetracycline in the treated wastewater is less than 50 μg / L, and the adsorption removal rate is greater than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com