Ocean catalase production bacteria and directional screening method

A technology of catalase and enzyme bacteria, which is applied in the field of marine bioengineering, can solve the problem of low catalase production and achieve the effects of low cost, wide industrial use value and high enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

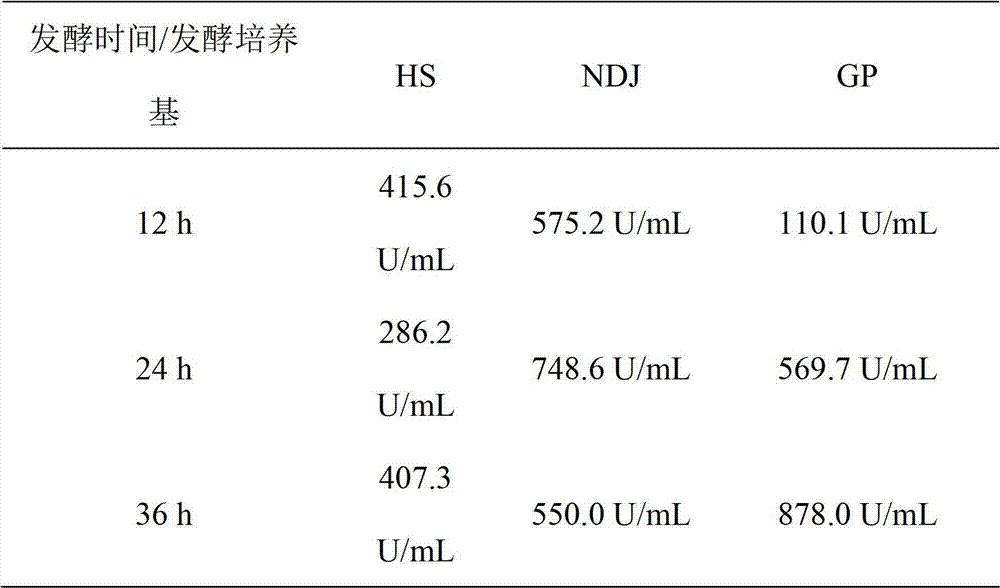

[0037] Example 1 Conventional method, liquid medium screening method and semi-solid medium screening method

[0038] Collect seawater samples, take 150 μL of gradient dilution and spread them on natural seawater oligonutrient medium plates, incubate at 28°C for about 7 days to observe the results, and pick single colonies for slant preservation. The strains with catalase activity were initially screened by 3% hydrogen peroxide bubbling method. The natural seawater oligonutrient medium is 0.5g / L yeast extract, 0.1g / L peptone, pH is 7.2, and the rest is natural seawater.

[0039] Take 4.5mL seawater sample and add it to 4.5mL sterile aged seawater, add filter-sterilized 30% hydrogen peroxide 4μL and filter-sterilized carbon and nitrogen sources (final concentration: 0.25% peptone, 0.25 %Casamino acid and 0.01% yeast extract). Shake enrichment culture at 28°C for about 4 days, dilute the enrichment solution to an appropriate multiple aseptically, spread the plate, and select a ...

Embodiment 2

[0043] Example 2 Isolation and screening of P.chinense CGMCC No.6043

[0044] Seawater samples were collected, and 4.5 mL of seawater samples were added to the semi-solid medium under sterile conditions, as well as carbon and nitrogen sources that had been pre-filtered and sterilized, with a final concentration of 0.25% peptone, 0.25% Casamino acid and 0.01% yeast extract. Shake enrichment culture at 28°C for about 4 days, dilute the enrichment solution to an appropriate multiple aseptically, spread the plate, and select a single clone for slant preservation.

[0045] The bacterial strain isolated by the above method is transferred to natural seawater liquid medium for shake flask fermentation, and the catalase activity re-screening is carried out by spectrophotometry. The natural seawater medium is: sterile aged seawater with a final concentration of 0.25% peptone, 0.25% Casamino acid and 0.01% yeast extract, pH 7.2.

[0046] The hydrogen peroxide stimulation method was opti...

Embodiment 3

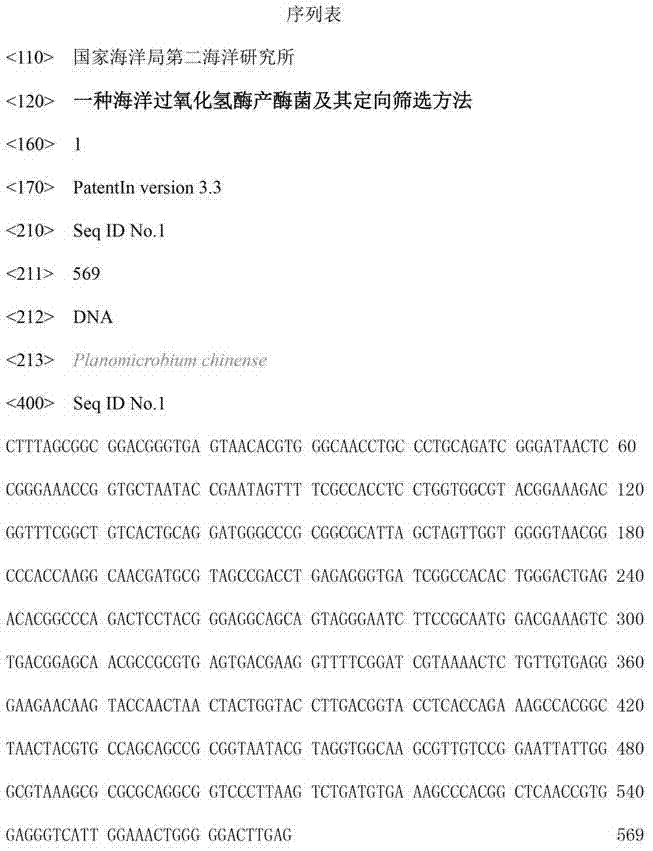

[0047] Example 3 Morphological identification and biological characteristics of P.chinense CGMCC No.6043

[0048] P.chinense (P.chinense) CGMCC No.6043 was inoculated in natural seawater liquid medium. To prepare solid medium, add 15g / L agar. 121°C damp heat sterilization for 20 minutes. After inoculation and culture, it was identified that the bacterium had the following characteristics: (1) Colony morphology: the colony was round, with a smooth surface, flat edges, slightly raised, and yellow. (2) Cell morphology: Gram-positive bacteria, under the cell microscope (Olympus, BX40), show motility, and the morphology is mostly spherical (0.8×1.0μm). (3) Physiological and biochemical characteristics: aerobic growth; hydrolyzed gelatin, non-hydrolyzed starch, casein, Tween 80, and aescin; can use glucose to produce acid, but cannot use sucrose, raffinose, xylan, lactose, and arabinose , cellobiose, xylose, rhamnose, melibiose, mannose or mannitol to produce acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com