Barrier type anode plate for non-ferrous metal electrowinning

A non-ferrous metal and anode plate technology, applied in the field of electrolysis, can solve the problems of high electrode cost, short life, poor conductivity, etc., and achieve the effect of improving adhesion and service life, reducing material cost, and reducing concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

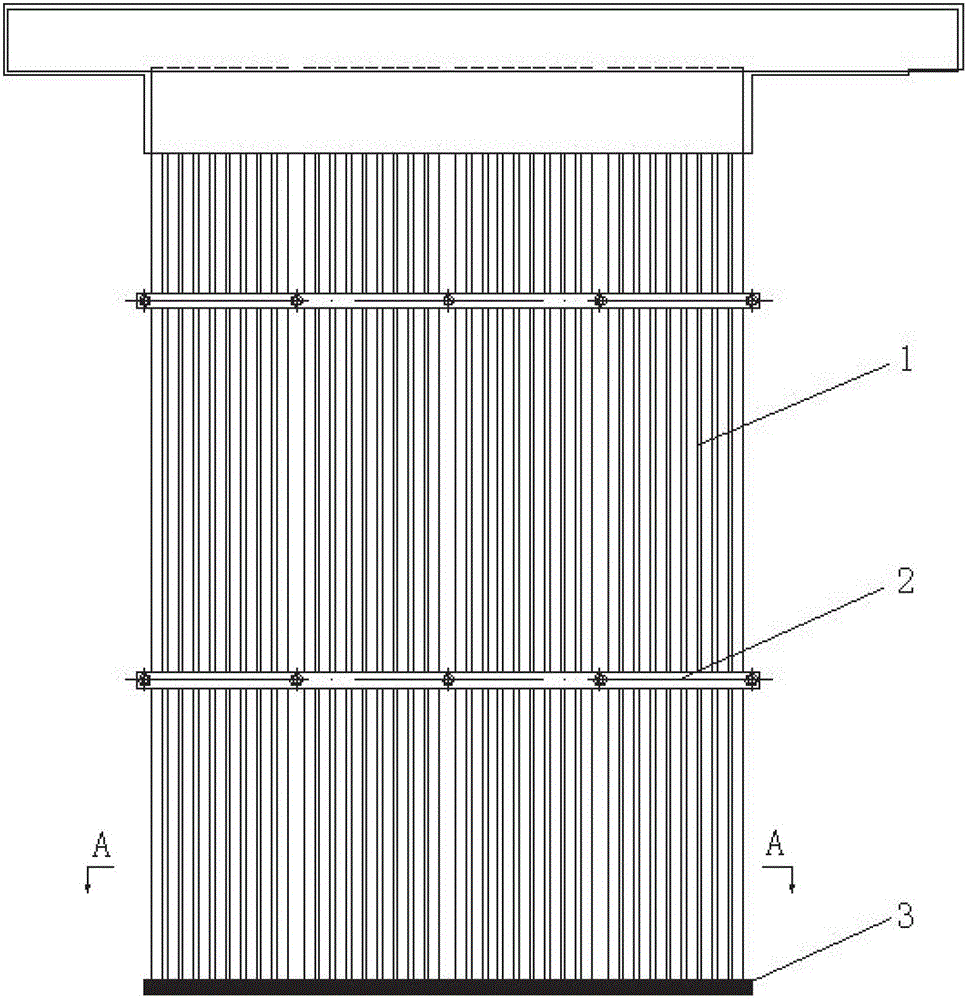

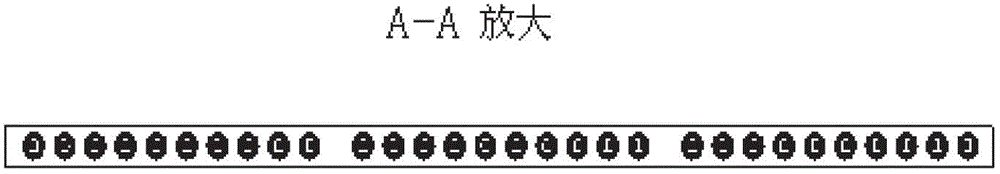

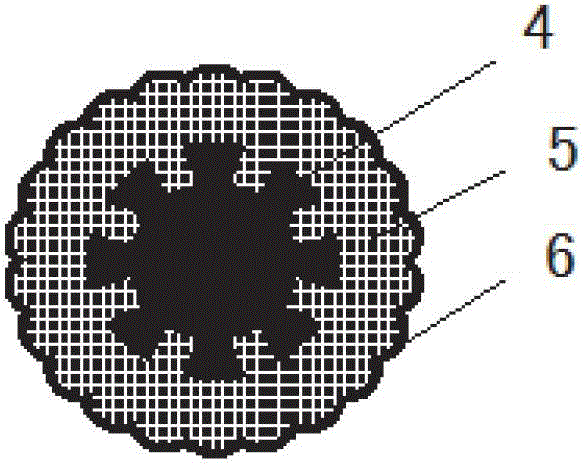

[0025] Embodiment 1: A fence type anode plate for electrowinning of non-ferrous metals. A lead-based multi-element alloy is compounded on an aluminum rod with a base material diameter of 4 to 6 mm to obtain a composite rod, and a zigzag pattern is drawn on the surface of the composite rod. The width of the pattern is 1 ~ 1.5mm, depth 0.5 ~ 1.0mm; then prepare PbO by electrodeposition on the surface of the zigzag pattern 2 -MnO 2 - Carbon nanotube conductive ceramic coating. Then 30 composite rods are clamped and fixed with insulating edge strips, and a lead-silver-calcium alloy layer with a thickness of 20 mm is cast at the bottom of the composite rods. The lead-based multi-element alloy composite rod is obtained by conventional smelting, ingot casting and drawing processes.

Embodiment 2

[0026] Embodiment 2: Composite lead-silver alloy is made on titanium rod with base material diameter of 4-6 mm to obtain a composite rod, and the surface of the composite rod is drawn into a corrugated pattern with a width of 1-1.5 mm and a depth of 0.5-1.0 mm. Finally, PbO is coated on the outer surface of the lead-silver alloy 2 -MnO 2 - Carbon nanotube conductive ceramic composite layer. Then 42 composite rods are clamped and fixed with insulating edge strips, and a lead-silver-calcium alloy layer with a thickness of 20 mm is cast at the bottom of the composite rods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com