Preparation method of heterogeneous anion exchange membrane

An anion exchange membrane, heterogeneous technology, applied in anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of low membrane ion conductivity, complex preparation process, polluted environment, etc., to achieve high ion exchange capacity, high Effect of ionic conductivity, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Prepare monomer slurry, take 99 parts by weight of polymerized monomer N-vinyl formamide (NVF), 1 part by weight of crosslinking agent divinylbenzene (DVB), 5 parts by weight of initiator benzoyl peroxide (BPO ), and mix evenly.

[0040] Cut out 10×10cm 2 PTFE porous membrane with a thickness of 10m, soaked in methanol solution, quickly immersed in the prepared monomer slurry components for a certain period of time, took out and wiped off the excess solvent on the surface, preheated on a hot stage at 80°C for 1min, covered on both sides A polyester sheet with a thickness of 100m is clamped in a clean glass plate. Put the glass plate on a hot stage at 80°C, and thermally polymerize it under a pressure of 0.3MPa for 5h.

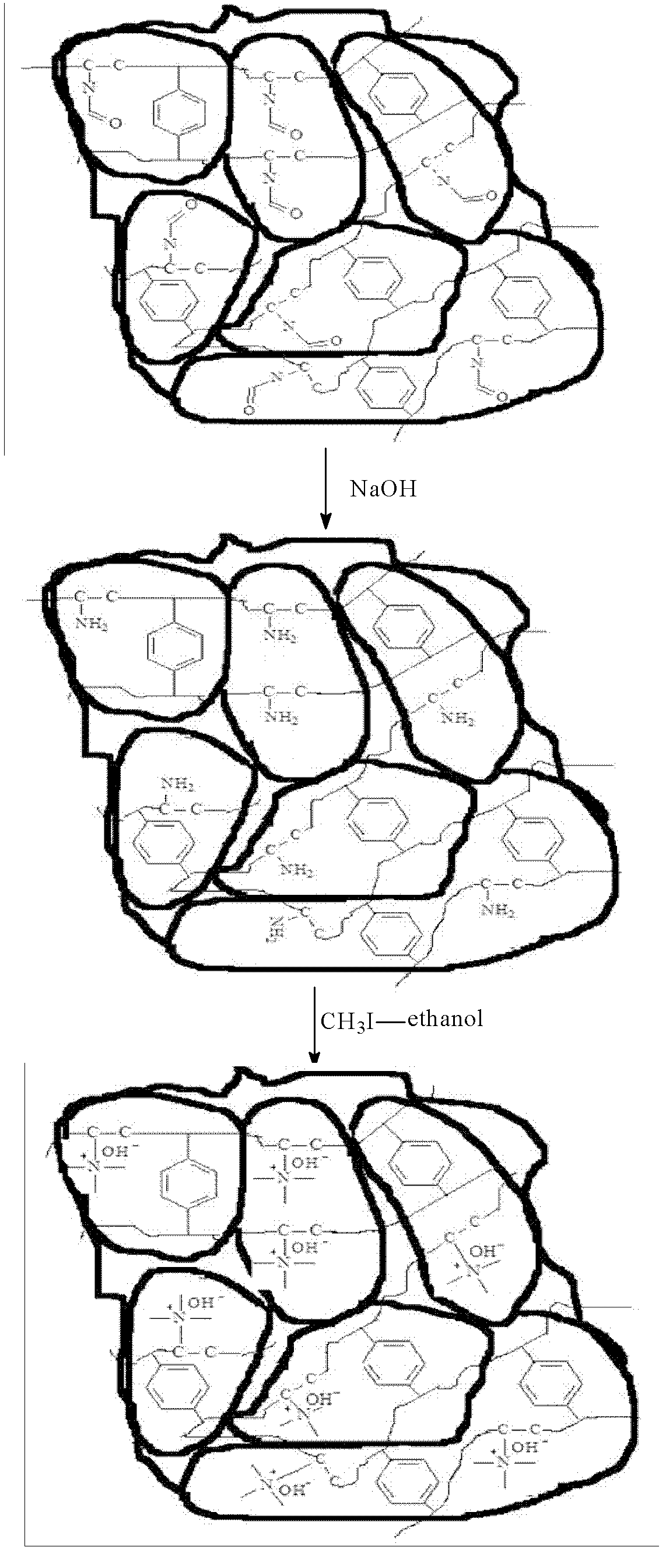

[0041]The obtained film was carefully peeled off from the polyester sheet, immersed in 5mol / L NaOH aqueous solution, and hydrolyzed at 80°C for 10h. The hydrolyzed film is soaked in 30wt% iodomethane-ethanol solution at room temperature for 10 hours, ...

Embodiment 2

[0045] Adopt the same operation process as embodiment 1. The difference from Example 1 is that the ammonification conditions are changed, and the hydrolyzed film is immersed in a 30 wt% iodomethane-ethanol solution at room temperature for 22 hours.

[0046] The room temperature water content and ion exchange capacity of the anion exchange membrane prepared by this example were 267.2wt% and 1.43mmol / g-dry membrane, respectively.

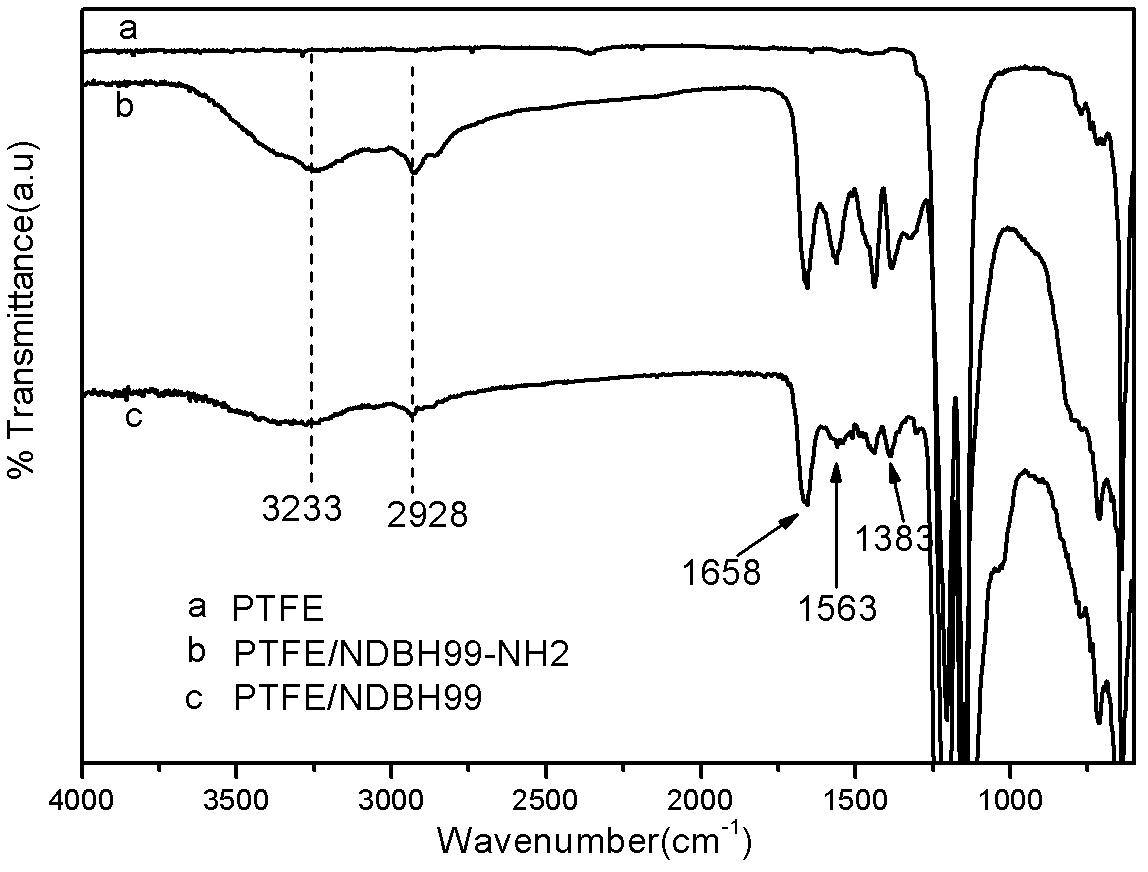

[0047] Such as figure 2 As shown, 2928 and 1658cm -1 represent -CH respectively 2 Stretch vibration peak and -C=C stretch vibration peak in benzene ring, 1563 and 1383 cm -1 represent -NH respectively 2 Bending vibration peak and -C-N group stretching vibration peak, but this information does not appear in the base film PTFE, which can prove that the monomer enters the porous PTFE and successfully polymerizes; figure 2 1563cm of middle curve c -1 Office-NH 2 The bending vibration peak is obviously weaker than curve b, which can prove that -NH...

Embodiment 3

[0051] Adopt the same operation process as embodiment 1. The difference from Example 1 is that the thermal polymerization conditions are changed to: 120° C. hot stage, thermal polymerization under 0.3 MPa pressure for 3 hours.

[0052] The ion exchange capacity of the anion exchange membrane prepared in this example is 0.84mmol / g-dry membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com