Graphene/inorganic semiconductor composite film and preparation method thereof

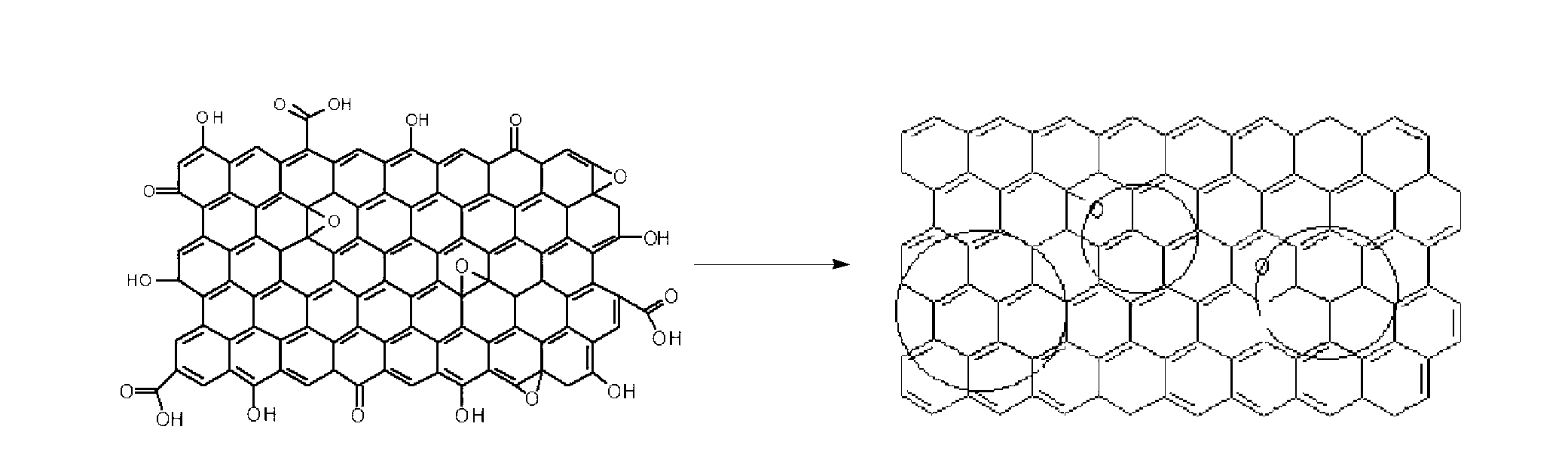

A technology of inorganic semiconductors and composite films, which is applied in the manufacture of cables/conductors, conductive layers on insulating carriers, electrical components, etc., can solve the problem of affecting the conductivity of graphene and the uniformity of films, and restricting the smooth transmission of graphene electrons and holes , It is difficult to meet the needs of flexible development of devices, etc., to achieve the effect of improving the transmission of holes or electrons, superior performance, and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of graphene oxide / SiC precursor gel:

[0038] Dissolve 3g of phenolic resin in 8.5mL of ethanol, add 12.5mL of tetraethyl orthosilicate and a small amount of 0.1M oxalic acid aqueous solution, then add the resulting mixed solution (20mL) into 1mg / mL graphene oxide aqueous solution (5mL) , ultrasonication for 1 h, then fully stirred and pre-hydrolyzed at a temperature of 38 ° C to 45 ° C, then added 5 mL of hexamethylene tetramine aqueous solution, and after standing still, the graphene oxide / SiC precursor gel was obtained.

[0039] Preparation of graphene oxide / SiC film:

[0040] 1) Add the graphene oxide / SiC precursor gel dropwise onto the substrate rotating at 3000rpm, and after spin coating for 30s, wash it twice with a mixed solution of ethanol and water;

[0041] 2) Dry the substrate obtained above in a vacuum oven at 120°C for 24h. Put it into a corundum tube, heat it up to 800°C at a rate of 4°C / min in an Ar atmosphere, then heat it up to 1200°C at ...

Embodiment 2

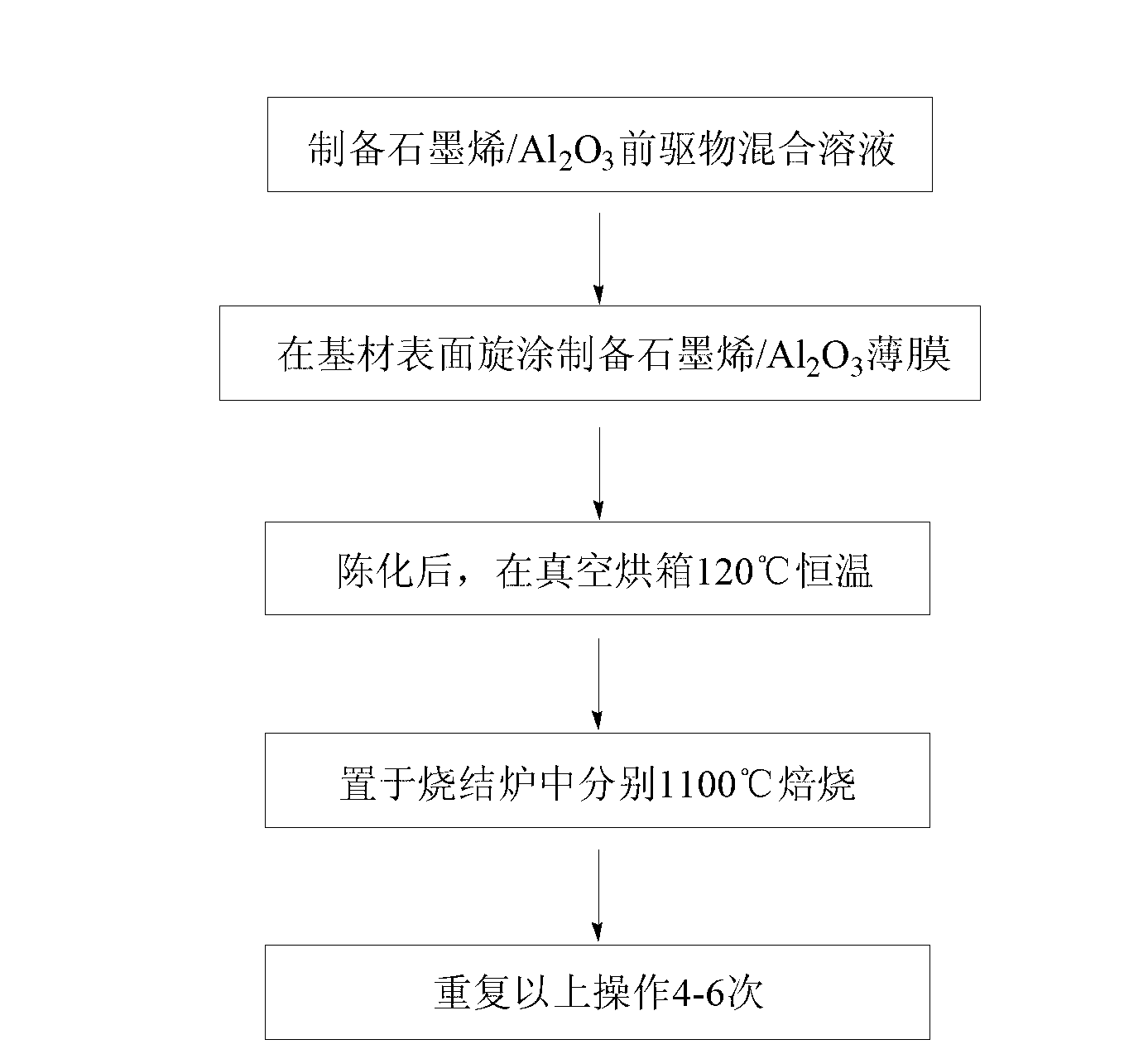

[0044] Graphene oxide / Al 2 o 3 Preparation of precursor sol:

[0045] Its preparation process is as follows figure 2 As shown, first weigh a certain amount of aluminum nitrate and dissolve it in 10mL distilled water to prepare a 0.5mol / L aluminum nitrate solution, then weigh a certain amount of citric acid, dissolve the citric acid in the aluminum nitrate solution, and prepare nitric acid The molar ratio of aluminum to citric acid is 1:2 solution, adjust the pH value with nitric acid and ammonia water, make the initial pH value of the solution is about 1, then add 2mL ethylene glycol as a dispersant, mix the solution (12mL) with 1mg / mL graphene aqueous solution (3mL) was stirred evenly to make a mixed solution. Put the mixed solution into a constant temperature water bath at 80°C and heat it for 12 hours to obtain graphene oxide / Al with certain viscosity and fluidity. 2 o 3 Precursor sol.

[0046] Graphene oxide / Al 2 o 3 Film preparation:

[0047] 1) The configured g...

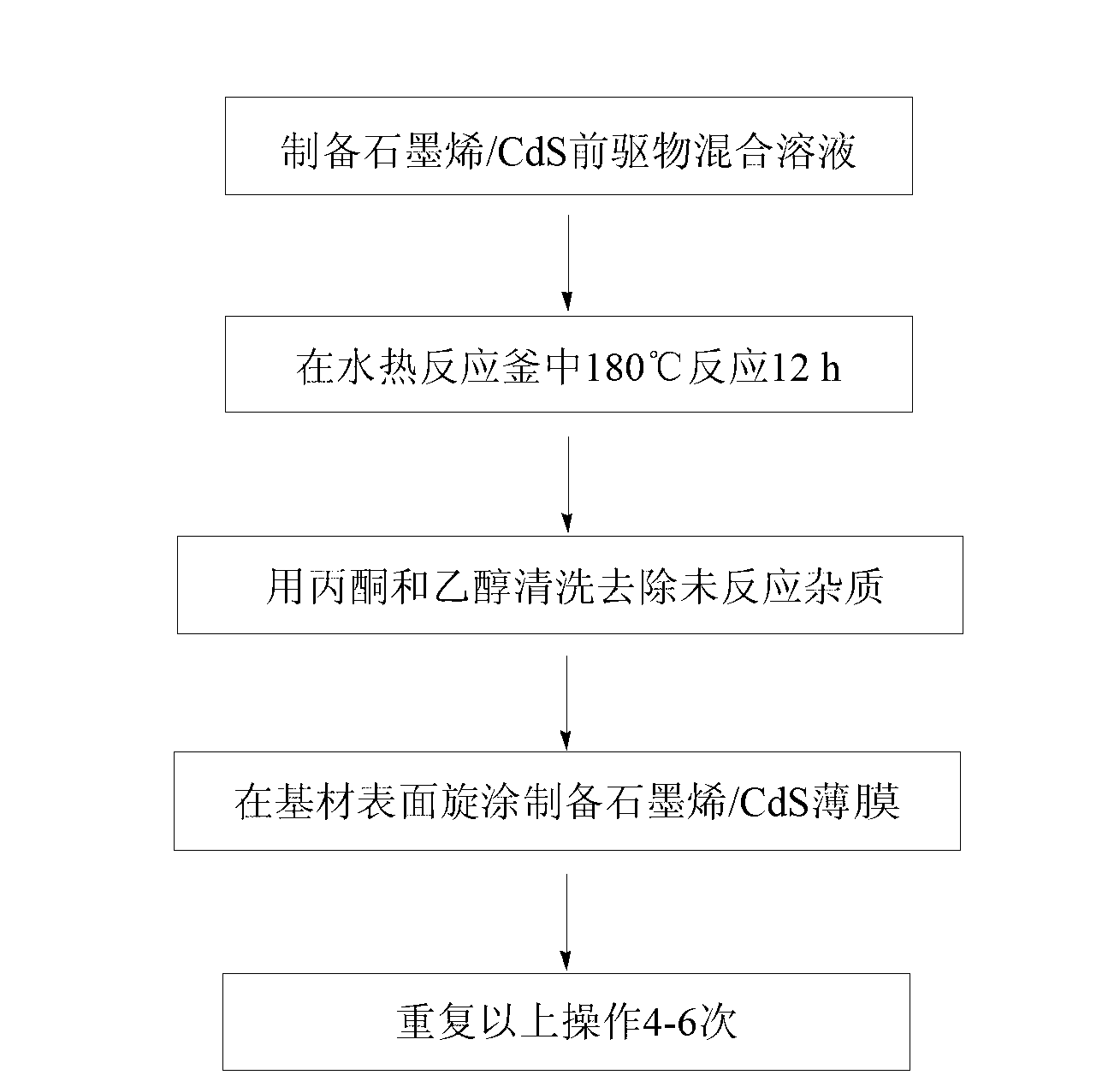

Embodiment 3

[0051] Graphene oxide / TiO 2 Preparation of precursor sol:

[0052] First, 17.02mL of Ti (OC 4 h 9 ) 4 Dissolve in 68.28mL of absolute ethanol, then add 4.80mL of diethanolamine, stir on a constant temperature magnetic stirrer at room temperature for 2h, then add H 2 O / C 2 h 5 OH (0.9mL / 9mL) mixed solution, finally add 1g of polyethylene glycol, stir for 10min, then add 1mg / mL graphene oxide aqueous solution (5mL), and stir thoroughly for 10h after ultrasonication for 30min to obtain a uniform graphene oxide / TiO 2 Precursor sol.

[0053] Graphene oxide / TiO 2 Film preparation:

[0054] 1) The substrate is ultrasonically cleaned 4-5 times in advance with deionized water, acetone and isopropanol to remove oil and impurities on the surface, and then treated with oxygen plasma to improve the adhesion of the substrate;

[0055] 2) Clean the substrate obtained above and immerse it in the prepared sol solution at a uniform speed. After standing for 10 seconds, pull the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com