Preparation method and application of acrylate wood-plastic composite compatibilization modifier

An acrylic and wood-plastic composite technology, which is applied in the field of wood-plastic composite material preparation, can solve problems such as poor interface compatibility, increase bonding strength, and weak bonding, and achieve good mechanical properties, increase composite ability, increase strength and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

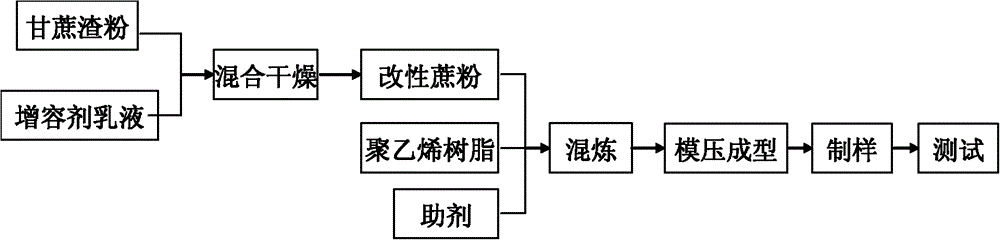

[0038] Example 1: Compression molding of polyethylene / bagasse wood-plastic composite material.

[0039] Step 1: Bagasse Pretreatment

[0040] First, crush the bagasse, and then use a vibrating sieve to screen out 40-80-mesh components, and pack them into bags for later use.

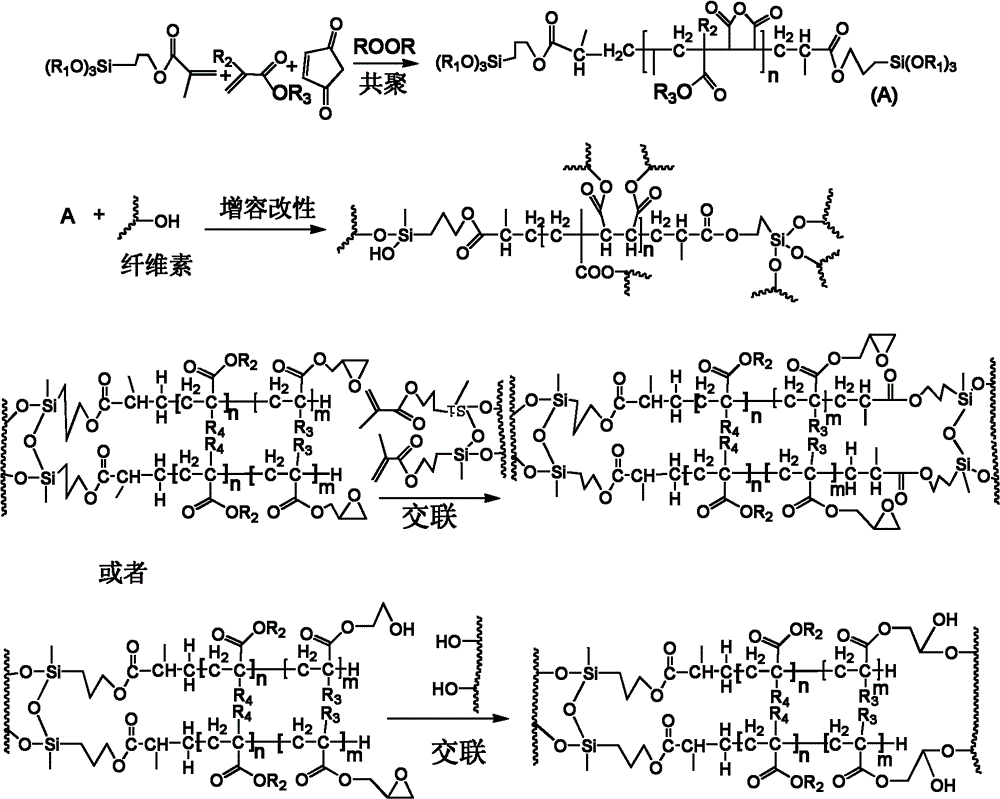

[0041] Step 2: Synthesis of Acrylate Compatibilizer

[0042] First, methyl methacrylate (MMA), butyl acrylate (BA), glycidyl methacrylate (GMA) and vinyl acetate (VAc) were mixed. Under the condition of adding 0.5% (mass ratio) of hydroquinone, distill under reduced pressure, remove the polymerization inhibitor, and store at low temperature in the dark; silane coupling agents KH-550 and KH-570 are distilled under reduced pressure, and put them in a refrigerator for sealed storage spare.

[0043] Add 120 mL of distilled water to a 250 mL three-neck flask, add 2.5 g of sodium p-dodecylbenzenesulfonate, 1.0 g of calcium stearate and 1.0 g of magnesium stearate and heat up to 90°C, stirring to fully ...

Embodiment 2

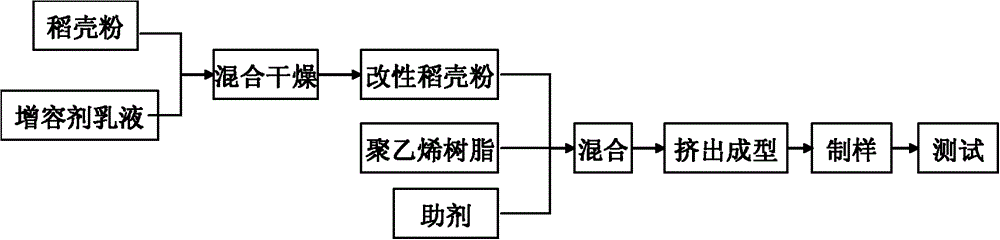

[0052] Embodiment 2: extrusion molding of polyethylene / rice husk powder wood-plastic composite material.

[0053] The first step: rice husk powder pretreatment

[0054] First, crush the rice husk, and then sieve the 40-80-mesh components with a vibrating sieve, and pack them into bags for later use.

[0055] Step 2: Synthesis of Acrylate Compatibilizer

[0056] First, methyl methacrylate (MMA), butyl acrylate (BA), glycidyl methacrylate (GMA) and vinyl acetate (VAc) were mixed. Under the condition of adding 0.5% (mass ratio) of hydroquinone, distill under reduced pressure, remove the polymerization inhibitor, and store at low temperature in the dark; silane coupling agents KH-550 and KH-570 are distilled under reduced pressure, and put them in a refrigerator for sealed storage spare. Add 800 mL of distilled water to a 2000 mL three-necked flask, put 25 g of sodium p-dodecylbenzenesulfonate, 15 g of polyvinyl alcohol 1788, 10 g of calcium stearate and 10 g of magnesium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com