Preparation method for organosilicon-modified crosslinking polyurethane emulsion

A technology of polyurethane emulsion and silicone, which is applied in the field of preparation of silicone-modified cross-linked polyurethane emulsion, which can solve the problems of expensive alkoxy silicone oil, high unit cost of emulsion, and reduced electron cloud density, and achieve excellent low temperature resistance, unit Low cost, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

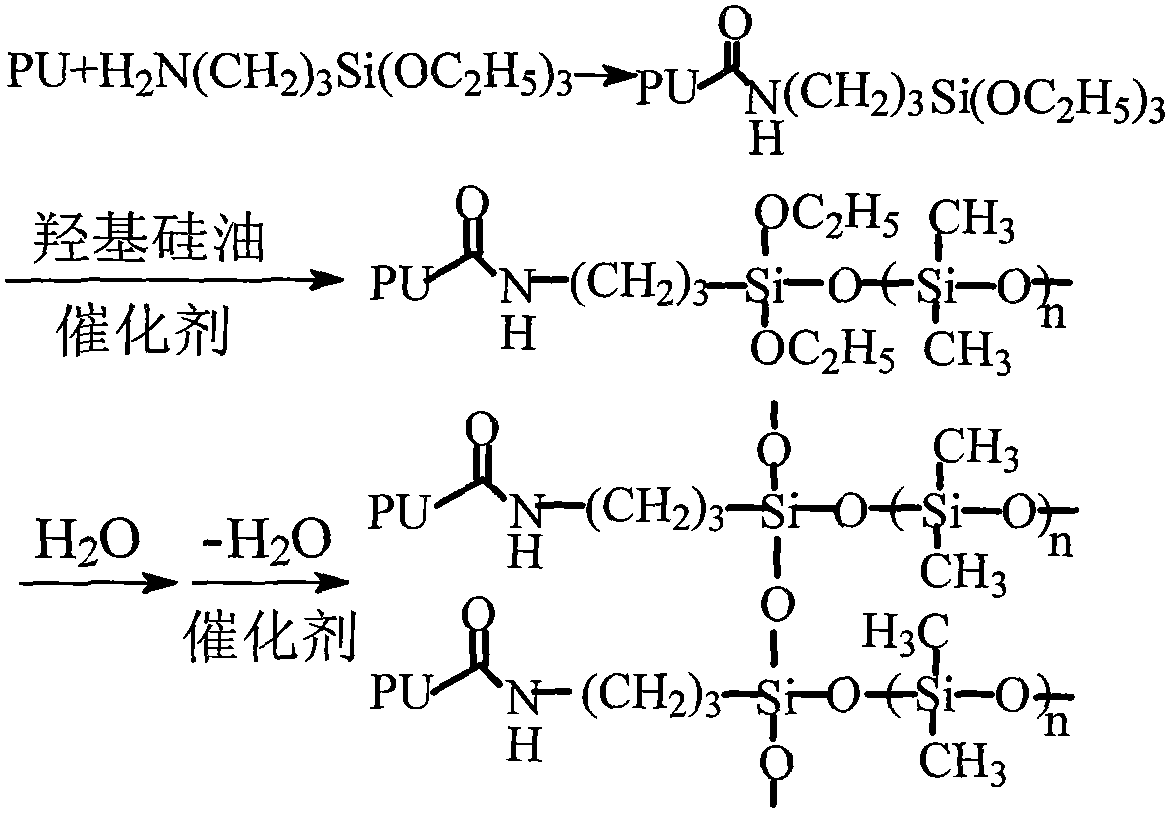

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Preparation of organosilicon-modified cross-linked polyurethane emulsion

[0025] In a 250ml there-necked flask with a reflux condenser and a thermometer, add toluene diisocyanate (TDI) 34g, the number average molecular weight after vacuum dehydration is 2000, and the hydroxyl value is equal to polyhexamethylene adipate diol of 55mgKOH / g 100g, react at 90°C constant temperature for 1.5h under mechanical stirring; cool down to 80°C, add dimethylolpropionic acid (DMPA) 5.0g, trimethylolpropane (TMP) 2.0g, acetone 20ml and continue to react for 1h, to obtain Hydrophilic modified PU prepolymer; add 40ml of acetone, wait until the system cools down to about 40°C, add 7.5g of diethylene glycol (DEG), 0.1g of dibutyltin dilaurate, and react to NCO at 60°C The content reaches the theoretical value (determined by the standard di-n-butylamine titration method); cool down to about 30°C, add 3g of aminopropyltriethoxysilane (KH-550) and 6g of hydroxyl silicone oil wit...

Embodiment 2

[0026] Embodiment 2: Preparation of organosilicon-modified cross-linked polyurethane emulsion

[0027] In a 250ml there-necked flask with a reflux condenser and a thermometer, add 39g of toluene diisocyanate (TDI), and the number-average molecular weight after vacuum dehydration is 2000, and the hydroxyl value is equal to polyhexamethylene adipate diol of 55mgKOH / g 100g, 5.6g of dimethylolpropionic acid (DMPA), react at a constant temperature of 80°C for 2h under mechanical stirring; add 40ml of acetone, wait for the system to cool down to about 40°C, add 8.5g of diethylene glycol (DEG), Dibutyltin dilaurate 0.1g, react at 60°C until the NCO content reaches the theoretical value (determined by standard di-n-butylamine titration method); cool down to about 30°C, add aminopropyltriethoxysilane (KH-550 ) 4g, 10g of hydroxyl silicone oil with a number average molecular weight of 1000, reacted at 40°C for 1h, added 4.2g of triethylamine under the action of high shear force at 800 r...

Embodiment 3

[0028] Embodiment 3: Preparation of organosilicon-modified cross-linked polyurethane emulsion

[0029]In a 250ml three-neck flask with a reflux condenser and a thermometer, add 38g of isophorone diisocyanate (IPDI), polytetrahydrofuran diol (PTMG) with a number average molecular weight of 2000 and a hydroxyl value equal to 55mgKOH / g after vacuum dehydration 100g, react at a constant temperature of 90°C for 2.5h under mechanical stirring; cool down to 80°C, add 6.5g of dimethylolpropionic acid (DMPA), 5.2g of trimethylolpropane (TMP), N,N-dimethylolpropane 20ml of formamide continued to react for 1 hour to obtain a hydrophilic modified PU prepolymer; add 60ml of acetone, wait for the system to cool down to about 40°C, add 4.5g of 1,4-butanediol (BDO) and 1.5g of ethylene glycol, 0.1 g each of dibutyltin dilaurate and stannous octoate, and 40 ml of N, N-dimethylformamide were reacted at 60 ° C until the NCO content reached the theoretical value (determined by standard di-n-butyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com