Air cleaning material, and preparation method and application thereof

A technology of air purification materials and substrates, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., to achieve the effects of low wind resistance, low purification cost, and quick and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.04 g of cetyltrimethylammonium bromide and dissolve it in 20 ml of ultrapure water, and ultrasonically dissolve until a homogeneous solution is formed. Put 0.25 g of cut filter cotton into the prepared cetyltrimethylammonium bromide solution and soak it. Weigh 0.25 g of potassium permanganate, and add potassium permanganate into the cetyltrimethylammonium bromide solution with filter cotton. Sonicate until the potassium permanganate is completely dissolved, then add 15 ml of methanol, and place the resulting solution in a water bath at 45° C. for 6 hours. Take out the filter cotton and dry it at 105° C. to obtain the filter cotton loaded with manganese oxide. At this time, manganese oxide has been coated on the surface of the substrate.

[0032] figure 1 It is the photo of the filter cotton of the present invention after it is loaded with manganese oxide. The color of the filter cotton before the load is white, and after the load ( figure 1 ) is dark, indica...

Embodiment 2

[0037] Weigh 0.04 g of cetyltrimethylammonium bromide and dissolve it in 20 ml of ultrapure water, and ultrasonically dissolve until a homogeneous solution is formed. Put 0.25 g of cut filter cotton into the prepared cetyltrimethylammonium bromide solution and soak it. Weigh 0.25 g of potassium permanganate, and add potassium permanganate into the cetyltrimethylammonium bromide solution with filter cotton. Sonicate until the potassium permanganate is completely dissolved, then add 5 ml of methanol, and place the resulting solution at room temperature to react for 10 hours. Take out the filter cotton and dry it to obtain the filter cotton loaded with manganese oxide.

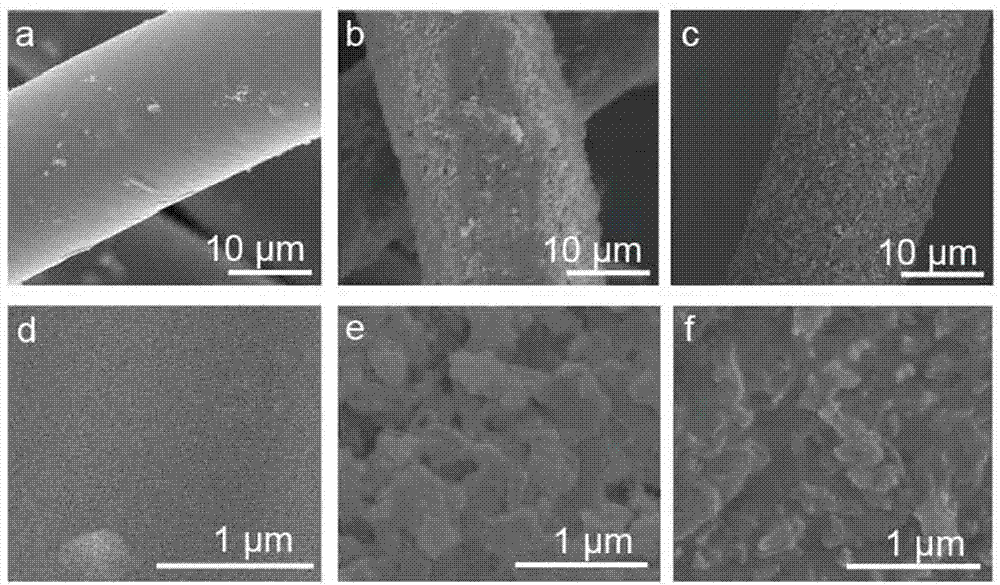

[0038] figure 2 Electron micrographs before and after the filter cotton is loaded with manganese oxide, by figure 2 c It can be seen that the smooth surface of the filter cotton is tightly covered by the manganese oxides generated by the reaction. figure 2 f is a high-magnification electron microscope phot...

Embodiment 3

[0042] Weigh 0.04 g of cetyltrimethylammonium bromide and dissolve it in 20 ml of ultrapure water, and ultrasonically dissolve until a homogeneous solution is formed. Put 0.25 g of cut filter cotton into the prepared cetyltrimethylammonium bromide solution and soak it. Weigh 0.15 g of potassium permanganate, and add potassium permanganate into the cetyltrimethylammonium bromide solution with filter cotton. Sonicate until the potassium permanganate is completely dissolved, then add 15 ml of methanol, and place the resulting solution at room temperature to react for 10 hours. Take out the filter cotton and dry it to obtain the filter cotton loaded with manganese oxide.

[0043] Soak the filter cotton sample loaded with manganese oxide in a mixed solution of 5% sulfuric acid and 0.1mol / L sodium oxalate, measure the content of manganese ions in the solution with an inductively coupled plasma emission spectrometer, and calculate the concentration of the loaded filter cotton The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com