High-temperature-resistant nanocomposite filtrate loss reducer for drilling fluid and preparation method thereof

A technology of nano-composite material and fluid loss reducing agent, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of lack of high temperature resistance, salt resistance, poor temperature resistance, and limited scope of use, etc. To achieve the effects of good temperature resistance and salt resistance, excellent characteristics, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

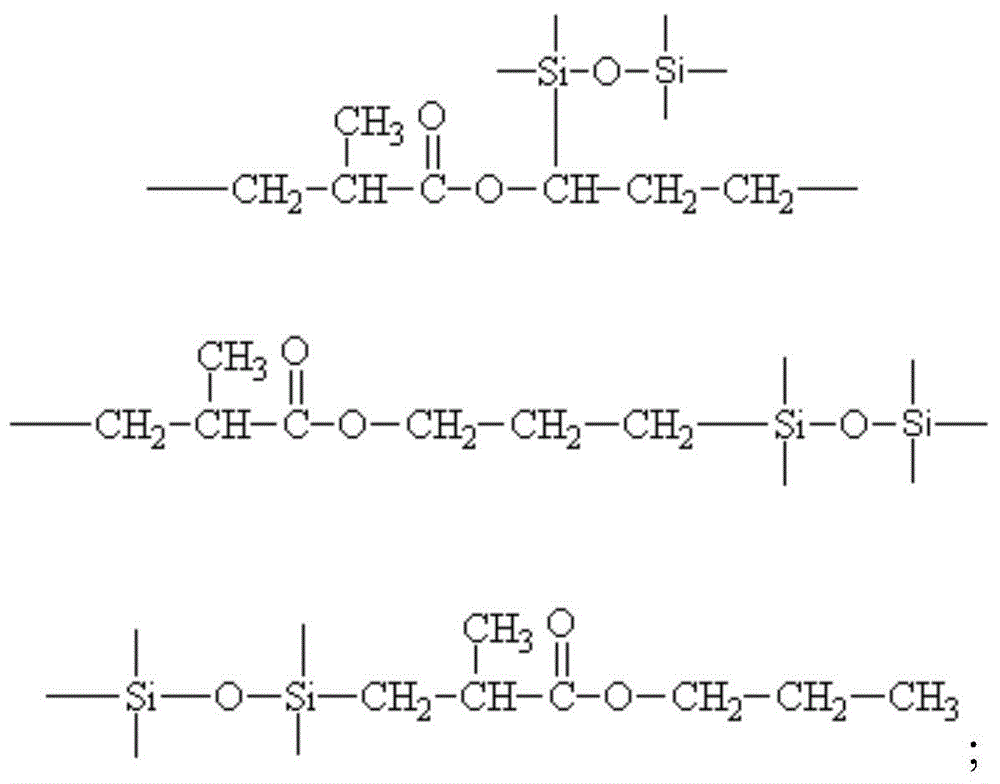

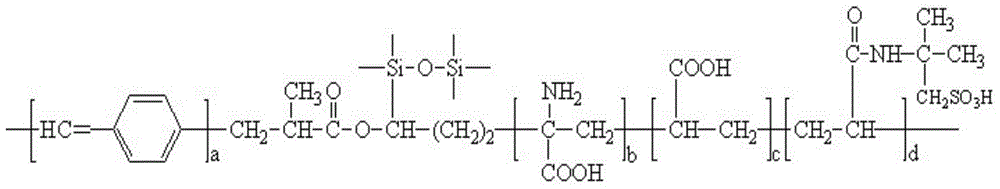

Method used

Image

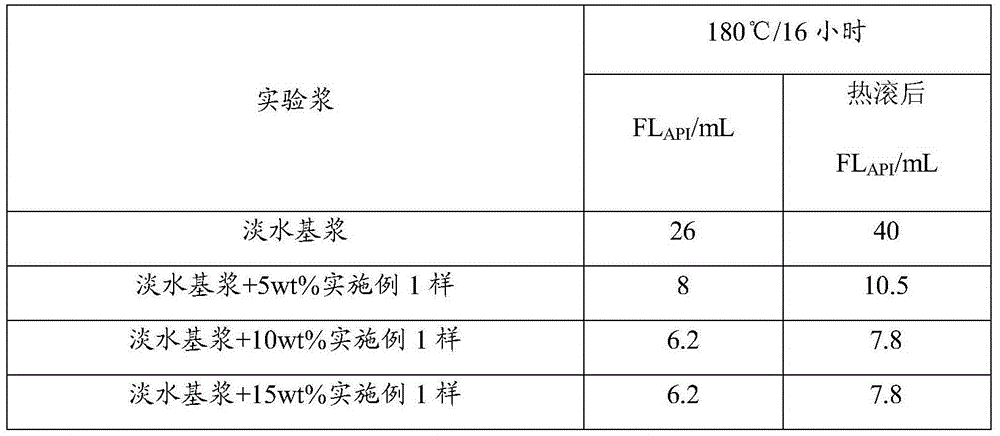

Examples

Embodiment 1

[0032] Under the protection of nitrogen, add a certain amount of nano-silica, silane coupling agent 3-methacryloxypropyltrimethoxysilane KH570 (the quality of KH570 is determined according to the particle size and quality of silica) into toluene solvent, stirred at room temperature for 3h, and separated by centrifugation (9500rpm, 30min) to obtain modified SiO 2 , and then rinsed with ethanol to remove excess silane coupling agent KH570, and then dried under vacuum to finally obtain powdered KH570 modified SiO 2 ,spare.

[0033] Styrene (St) was washed with 5% NaOH until light yellow, then washed with distilled water until neutral, dried over anhydrous magnesium sulfate, and then distilled under reduced pressure, stored in a refrigerator at 4 °C for later use.

[0034] Weigh a certain amount of lauryl sulfuric acid emulsifier and dissolve it in a certain amount of deionized water to form an aqueous solution; dissolve hexadecane HD in styrene monomer, stir to make it completel...

Embodiment 2

[0039] Dissolve dodecyltrimethylammonium bromide or sodium dodecylbenzenesulfonate in a certain amount of deionized water; dissolve hexadecane HD in styrene monomer, stir to dissolve HD completely, and then add Modified SiO 2 2.5wt%, and under the condition that the fine emulsification ultrasonic power is 300W, carry out ultrasonic fine emulsification on the monomer phase body for 20min to obtain the monomer fine emulsion;

[0040] Pour the monomer miniemulsion and N,N-dimethylacrylamide or N,N-diethylacrylamide or N-methylolacrylamide, acrylic acid, AMPS mixed solution with a mass ratio of 10:2:2 into the reaction bottle;

[0041] Stir the mixed solution in the reaction bottle and pass nitrogen gas for 15 minutes, adjust the mixed solution in the reaction bottle with NaOH solution to make the pH range 9.0, and heat up to a polymerization temperature of 50°C, then put azobisisobutyronitrile , under the initiation of azobisisobutyronitrile, polymerize to obtain high temperatu...

Embodiment 3

[0043] Dissolve sodium dodecylsulfonate in a certain amount of deionized water; dissolve hexadecane HD in styrene monomer, stir to dissolve all HD, and then add modified SiO 22.5wt%, and under the condition that the fine emulsification ultrasonic power is 300W, carry out ultrasonic fine emulsification on the monomer phase body for 20min to obtain the monomer fine emulsion;

[0044] Mix the monomer miniemulsion and N-vinylmethylacetamide or N-vinylethylacetamide or diacetone acrylamide, acrylic acid, 2-acrylamido dodecyl sulfonate at a mass ratio of 10:2:2 Pour the mixed solution of acid or 2-acrylamido tetradecyl sulfonic acid or 2-acrylamido hexadecyl sulfonic acid into the reaction flask.

[0045] Stir the mixed solution in the reaction bottle and pass nitrogen gas for 15 minutes, adjust the mixed solution in the reaction bottle with NaOH solution to make the pH range 9.0, and heat up to a polymerization temperature of 50°C, then put azobisisobutyronitrile , under the initi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com