Preparation method of nano-cable-connected ternary composite electrode material

An electrode material and ternary composite technology, which is applied in hybrid capacitor electrodes, spinning solution preparation, circuits, etc., can solve the problems of poor power performance of supercapacitors with ternary composite electrodes, poor conductivity of molecular sieves, etc., and improve electrochemical stability Sexuality, high power density, and the effect of smooth ion channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of graphene-ruthenium oxide nanosheets and aniline and o-fluoroaniline polymer-ruthenium oxide nanocable composites

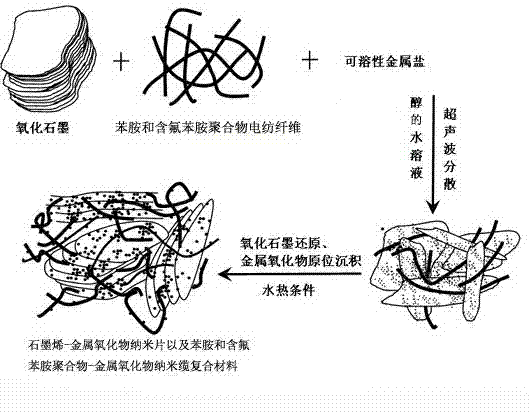

[0031] process such as figure 1 As shown, the specific preparation steps are as follows:

[0032] 1. Preparation of aniline and o-fluoroaniline polymers

[0033] With 0.02mol aniline and 0.01mol o-fluoroaniline as polymerization monomers and 0.015mol ammonium persulfate as oxidant, the polymerization reaction is carried out in 0.3L aqueous solution of camphorsulfonic acid with a concentration of 1mol / L. The reaction temperature is 0°C and the reaction time is 24h, precipitate the polymerization reaction product in acetone of 10 times the volume of the polymerization reaction product, wash the precipitate with dilute hydrochloric acid and acetone until the filtrate is clear, dry the washed precipitate in vacuum at 80°C for 6 hours, Aniline and o-fluoroaniline polymers;

[0034] 2. Preparation of aniline and o-fluoroaniline polyme...

Embodiment 2

[0040] Example 2 Graphene-tin oxide nanosheets and aniline and 2,4-difluoroaniline polymer-tin oxide nanocable composites

[0041] process such as figure 1 As shown, the specific preparation steps are as follows:

[0042] 1. Preparation of aniline and 2,4-difluoroaniline polymers

[0043] Use 0.025mol aniline and 0.025mol 2,4-difluoroaniline as polymerization monomers, use 0.05mol ferric chloride as oxidant, carry out polymerization reaction in 1L sulfuric acid solution with a concentration of 0.1mol / L, and the reaction temperature is 20 ℃, reaction time 12h, precipitate the polymerization reaction product in acetone with 5 times the volume of the polymerization reaction product, wash the precipitate with dilute hydrochloric acid and acetone until the filtrate is clear, and place the washed precipitate at 40°C Vacuum drying for 24 hours to obtain aniline and 2,4-difluoroaniline polymer;

[0044] 2. Preparation of aniline and 2,4-difluoroaniline polymer electrospun fibers ...

Embodiment 3

[0050] Example 3 Preparation of graphene-titanium oxide nanosheets and aniline and p-trifluoromethylaniline polymer-titanium oxide nanocable composites

[0051] process such as figure 1 As shown, the specific preparation steps are as follows:

[0052] 1. Preparation of aniline and p-trifluoromethylaniline polymer

[0053] With 0.01mol aniline and 0.02mol p-trifluoromethylaniline as polymerization monomers, 0.06mol potassium permanganate as oxidant, carry out polymerization reaction in 0.3L perchloric acid aqueous solution whose concentration is 0.5mol / L, the reaction temperature 50°C, reaction time 1h, precipitate the polymerization reaction product in acetone with 8 times the volume of the polymerization reaction product, wash the precipitate with dilute hydrochloric acid and acetone until the filtrate is clear, and wash the precipitate at 60 Vacuum drying at 12 °C to obtain aniline and p-trifluoromethylaniline polymers;

[0054] 2. Preparation of aniline and p-trifluorom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com