Coated microcapsule of lactic acid bacteria and its preparation method

A lactic acid bacteria microcapsule, lactic acid bacteria technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of intolerant of high temperature of feed, inability to release quickly, low activity of lactic acid bacteria, etc., to enhance the protection effect, enhance heat resistance, good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

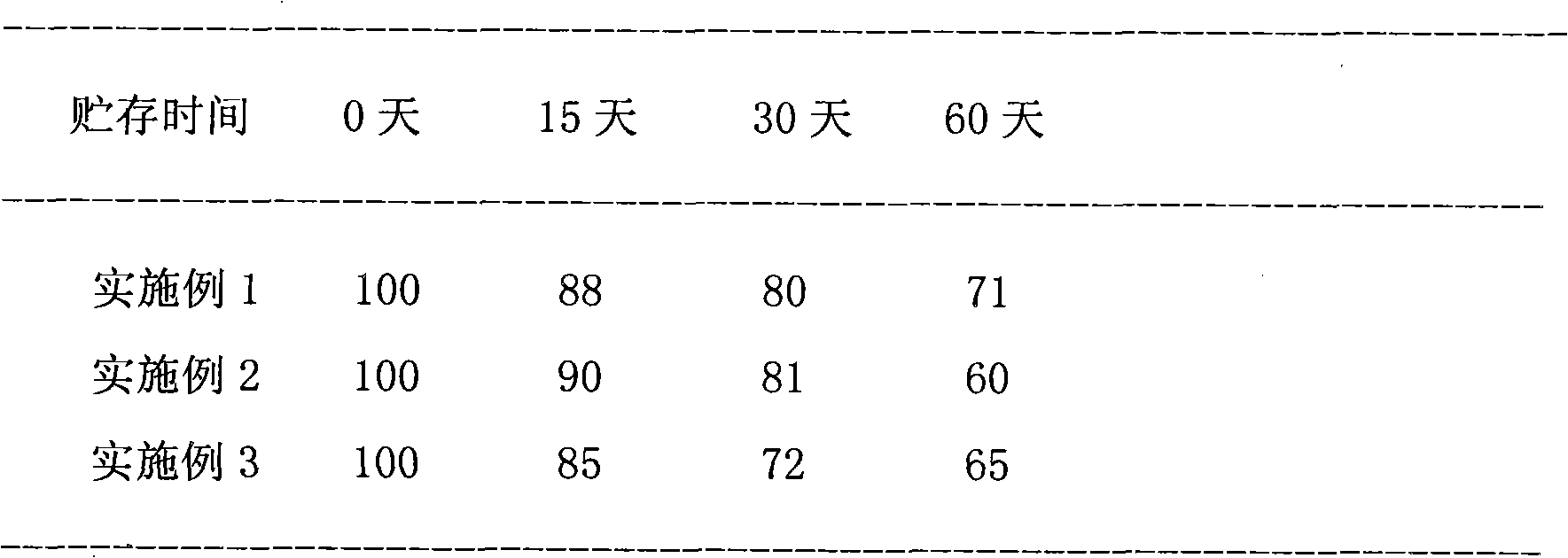

Embodiment 1

[0029] Use a culture medium, which includes components A, B, C and D, wherein the component A is one of beef extract or peptone, yeast extract, skimmed milk / powder, soybean peptide, tryptone, soybean powder or more mixtures; the component B is a mixture of one or more of lactose, glucose, tomato juice, malt extract; the component C is Tween-80, cysteine, carrot juice, potato One or more mixtures in juice, scallion juice, oyster mushroom juice; the component D is one or more mixtures of NaCI, KH2PO4, diammonium citrate, sodium acetate, MgSO4, the culture medium Sterilize at 121°C for 15-30 minutes, and cool to room temperature.

[0030] A strain of lactic acid bacteria (such as Lactobacillus plantarum) is isolated from the intestines of healthy animals, inserted into the above medium, and cultivated at 25-42°C for 12 hours; the culture solution is centrifuged at 4000r / min for 30min to obtain the lactic acid bacteria mud;

[0031] Dilute the lactic acid bacteria slime with ste...

Embodiment 2

[0035] Isolate a strain of lactic acid bacteria (such as Streptococcus faecalis) from the intestinal tract of healthy animals, insert it into the medium described in Example 1, and cultivate it at 25~42°C for 12 hours; , and centrifuged for 30min to obtain the lactic acid bacteria slime; dilute the lactic acid bacteria slime with sterilized physiological saline, add skim milk powder with 3% total weight of the lactic acid bacteria slime, and obtain a live bacteria concentration of 10 9 cfu / mL lactic acid bacteria concentrate.

[0036] Adopt FLP type fluidized granulation coating drier, put microcrystalline cellulose: sucrose: cornstarch: 2: 3: 5 (weight ratio) the pill-making auxiliary material 2kg that forms into pill-making pot, spray into above-mentioned lactic acid bacteria at the same time Concentrate, the weight ratio of pelleting auxiliary materials and lactic acid bacteria concentrate is 1: 2, and spray twice; the process conditions of the fluidized granulation coating...

Embodiment 3

[0040] A strain of lactic acid bacteria (such as Lactobacillus acidophilus, and of course Lactobacillus fermentum or Lactobacillus casei) was isolated from the intestinal tract of a healthy animal, inserted into the medium described in Example 1, and cultivated at 25-42°C 12 hours; under the condition of 4000r / min, the culture solution was centrifuged for 30min to obtain the lactic acid bacteria sludge; the lactic acid bacteria sludge was diluted with sterilized physiological saline, and the skimmed milk powder with 10% of the total weight of the lactic acid bacteria sludge was added to obtain the live bacteria concentration of 10 11 CFU of lactic acid bacteria concentrate.

[0041] Adopt FLP type fluidized granulation coating dryer, according to sucrose: maltodextrin: proteoglycan: 2:3:4 (weight ratio) the pill-making auxiliary material 2kS puts into the pill-making pot, sprays into above-mentioned lactic acid bacteria concentration at the same time liquid, the weight ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com