Semi-synthesis method of luteolin and galuteolin as well as luteolin rutinoside

A technology of luteolin and luteolin, which is applied in the field of chemistry and medicine, and can solve the problems of large environmental pollution, difficult recycling, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

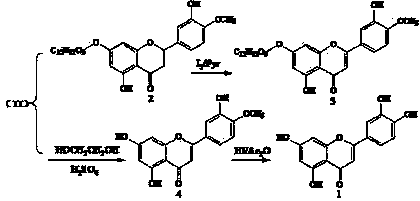

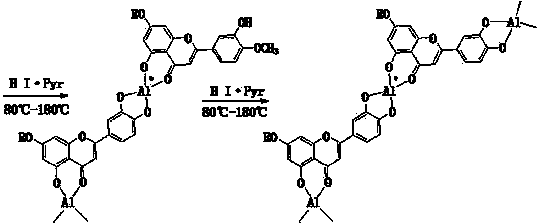

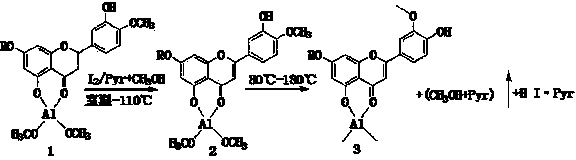

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of Luteolin-7-O-Rutinoside from Hesperidin

[0044]Quickly weigh 3.5g of anhydrous aluminum chloride (AR) into a 250ml iodine measuring bottle, quickly add 15ml of pyridine (AR), shake well, add 8ml of methanol (AR), after 2min, add 16.5g of 92% hesperidin , stir for 2 minutes, add 6.8g of iodine (AR), add 7ml of methanol (AR), stir for 2 minutes, connect a condenser tube or an air condenser tube to the end of the iodine measuring bottle, and react in a closed manner at 80°C (to prevent the absorption of moisture in the air), every 1h Stir once, and form a homogeneous solution after 2 hours, and continue to seal the reaction for 6 hours (complete dehydrogenation). Distill in an air bath at 114°C for 15 hours (demethylation reaction, the bottle changes from solution to solid, soft when hot, hard when cooled), place at 80°C, add 10ml ethanol and 10ml glycerol, and Keep warm at 80°C for 2h, the solid turns into a solution, add 1.0g of hydrosulfite, ...

Embodiment 2

[0045] Example 2 Preparation of Luteolin-7-O-Rutinoside from Hesperidin by Acid Hydrolysis to Obtain Luteolin and Luteolin

[0046] Quickly weigh 3.5g of anhydrous aluminum chloride (AR) into a 250ml iodine measuring bottle, quickly add 15ml of pyridine (AR), shake well, add 8ml of methanol (AR), after 2min, add 16.5g of 92% hesperidin , stir for 5 minutes, add 6.8g of iodine (AR), add 7ml of methanol (AR), stir for 3 minutes, connect a condenser or air condenser to the end of the iodine measuring bottle, and react in a closed manner at 80°C (to prevent the absorption of moisture in the air), every 1h Stir once, and form a homogeneous solution after 2 hours, and continue to seal the reaction for 6 hours (complete dehydrogenation). Distill in an air bath at 112°C for 17h (demethylation reaction, the bottle changes from solution to solid, soft when hot, hard when cooled), place at 80°C, add 20ml of ethanol, and keep at 80°C for 3h, Turn the solid into a solution, add 1.0g of...

Embodiment 3

[0047] Example 3 Preparation of luteolin from hesperidin-7-O-rutinoside by acid-alcohol solution hydrolysis to obtain luteolin

[0048] Quickly weigh 3.5g of anhydrous aluminum chloride (AR) into a 250ml iodine measuring bottle, quickly add 15ml of pyridine (AR), shake well, add 8ml of methanol (AR), after 2min, add 16.5g of 92% hesperidin , stir for 5 minutes, add 6.8g of iodine (AR), add 7ml of methanol (AR), stir for 3 minutes, connect a condenser or air condenser to the end of the iodine measuring bottle, and react in a closed manner at 80°C (to prevent the absorption of moisture in the air), every 1h Stir once, and form a homogeneous solution after 2 hours, and continue to seal the reaction for 6 hours (complete dehydrogenation). Distill in an air bath at 116°C for 15h (demethylation reaction, the bottle changes from solution to solid, soft when hot, hard when cooled), place at 80°C, add 20ml of ethanol, and keep at 80°C for 3h, Turn the solid into a solution, add 1.0g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com