Carboxylesterase D-1CarE3 cell surface display system and whole-cell catalyst as well as preparation method and application of whole-cell catalyst

A whole-cell catalyst and cell surface technology, applied in biochemical equipment and methods, methods based on microorganisms, bacteria, etc., can solve the problems of limited popularization and application, complicated collection, limited enzyme production ability of wild strains, etc., and achieve the preparation method and Ease of use and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

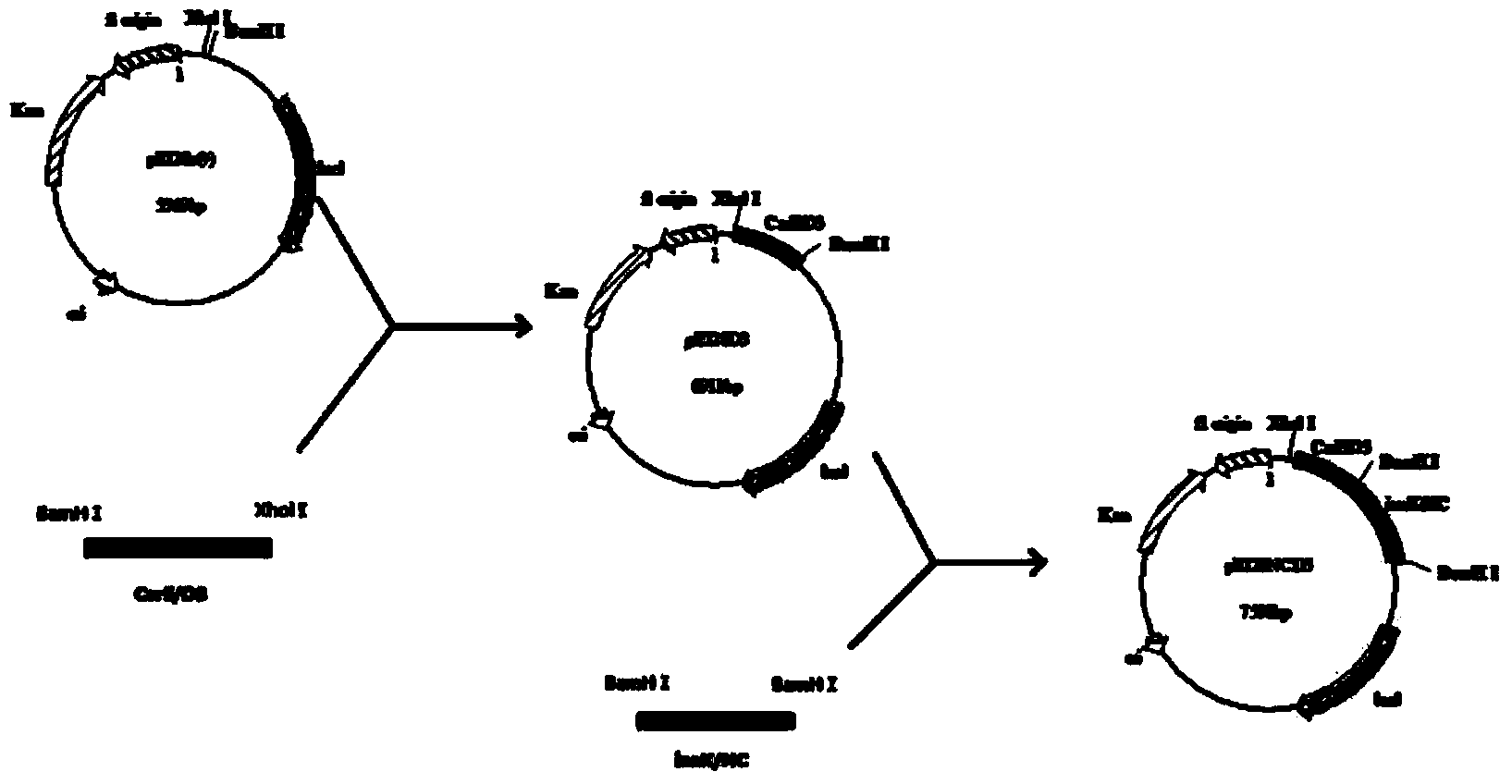

[0022] Embodiment 1: Construction of pET28NCD3 plasmid

[0023] Alicyclobacillus D-1 genomic DNA extraction: CTAB lysis method, the specific steps are: centrifuge the fresh bacterial liquid cultured in liquid for 12 hours, and add 800 μL solution Ⅰ (20mM Tris, pH8.0, 2mMNa 2 -EDTA, final concentration 20mg / mL lysozyme), keep warm at 37℃ for 30min, add 100μL 10% SDS and mix upside down, add 10μL 10mg / mL proteinase K, keep warm at 37℃ for 30min, add 150μL 5MNaCl and 150μL 10%CTAB solution and mix upside down Homogenize, keep warm at 65°C for 20min, add an equal volume of phenol / chloroform / isopropanol (volume ratio 25:24:1) for extraction, centrifuge at 12000rpm at 4°C for 10min, take the supernatant in chloroform / isopropanol (volume Ratio 24:1) to extract again to remove impurity proteins, centrifuge at 12000rpm at 4°C for 10min, then take the supernatant and add 2 times the volume of absolute ethanol and 1 / 10 volume of pH5.23M NaAc, precipitate at -70°C for 1h, 4°C Centrifuge ...

Embodiment 2

[0034] Embodiment 2: the preparation of engineering bacteria BL21 (DE3) / NCD3 whole cell catalyst

[0035] Take the engineered bacteria BL21(DE3) / NCD3 and the empty plasmid Escherichia coliBL21(DE3) strain containing only pET-28a(+), and inoculate the LB culture medium containing 50 μg / mL kana resistance at a volume ratio of 0.1% In this method, shake rapidly at 37°C for 12 hours, and then inoculate the activated bacterial solution into fresh LB induction culture medium with an inoculum of 1% volume ratio, and culture with shaking at 37°C for 3-4 hours, until the cell density OD600=0.5 or so, Add a final concentration of 0.05mMIPTG to induce culture at 20°C for 20 hours, centrifuge at 12,000rpm for 5 minutes, collect the bacteria, and freeze them into dry powder in an ultra-low temperature freezer vacuum dryer, which is the whole-cell catalyst D-1CarE3.

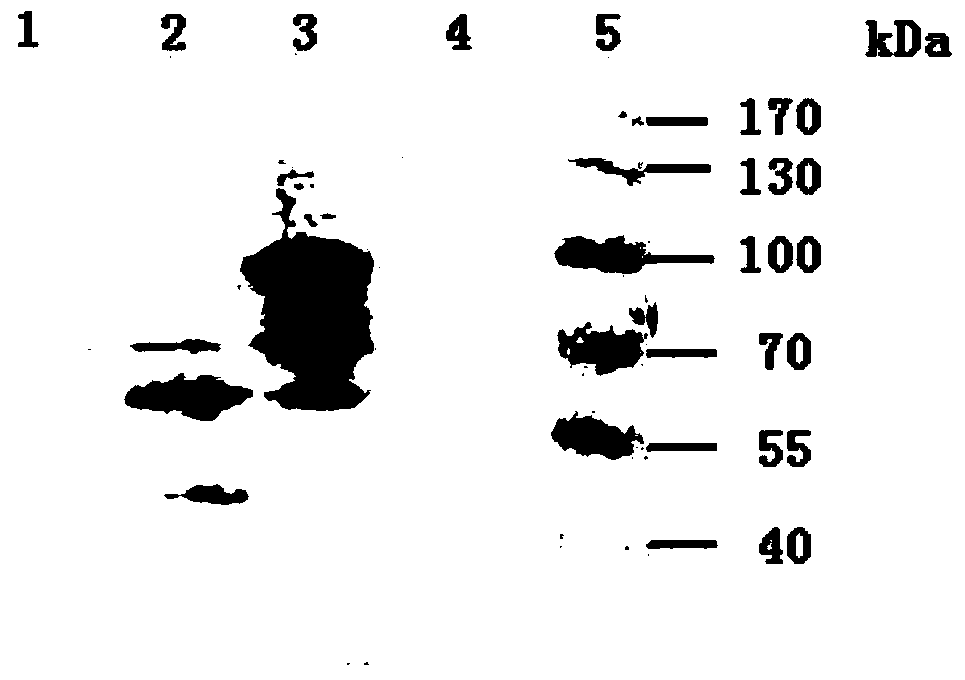

[0036] For the separation of cell components, take an appropriate amount of the above-mentioned centrifuge to collect the ce...

Embodiment 3

[0038] Embodiment 3: the application of engineering bacteria BL21 (DE3) / NCD3 whole cell catalyst

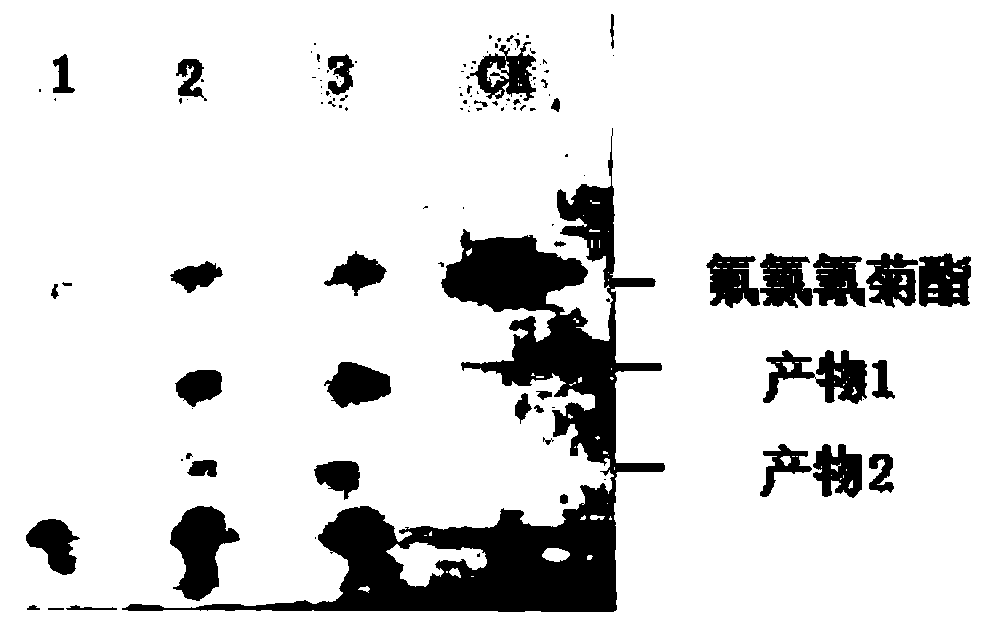

[0039] Weigh 1 mg of the whole-cell catalyst D-1CarE3 described in Example 2 and add 100 μl of 100 mg / ml cyfluthrin in acetone solution to shake for 60 minutes at room temperature, add an equal volume of n-hexane for extraction, centrifuge to take an appropriate amount of the upper layer and put it on a silica gel G plate. Thin-layer chromatography analysis, developed with n-hexane: acetone volume ratio 4:1 as the developing agent, naturally air-dried silica gel G plate, fumigated with bromine steam for 5 seconds, sprayed with 0.1% benzylidine acetone solution, and after air-dried, irradiated with ultraviolet light for 2 minutes to develop color ( image 3 ), the results show that the whole-cell catalyst D-1CarE3 can catalyze the pyrethroid pesticide cyfluthrin to form two products 1 and 2, which can be used in the treatment of pyrethroid pesticide pollution.

[0040] Put the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com