Molybdenum trioxide in-situ cladding nitrogen-doped carbon nanotube composite electrode material as well as preparation method thereof and application

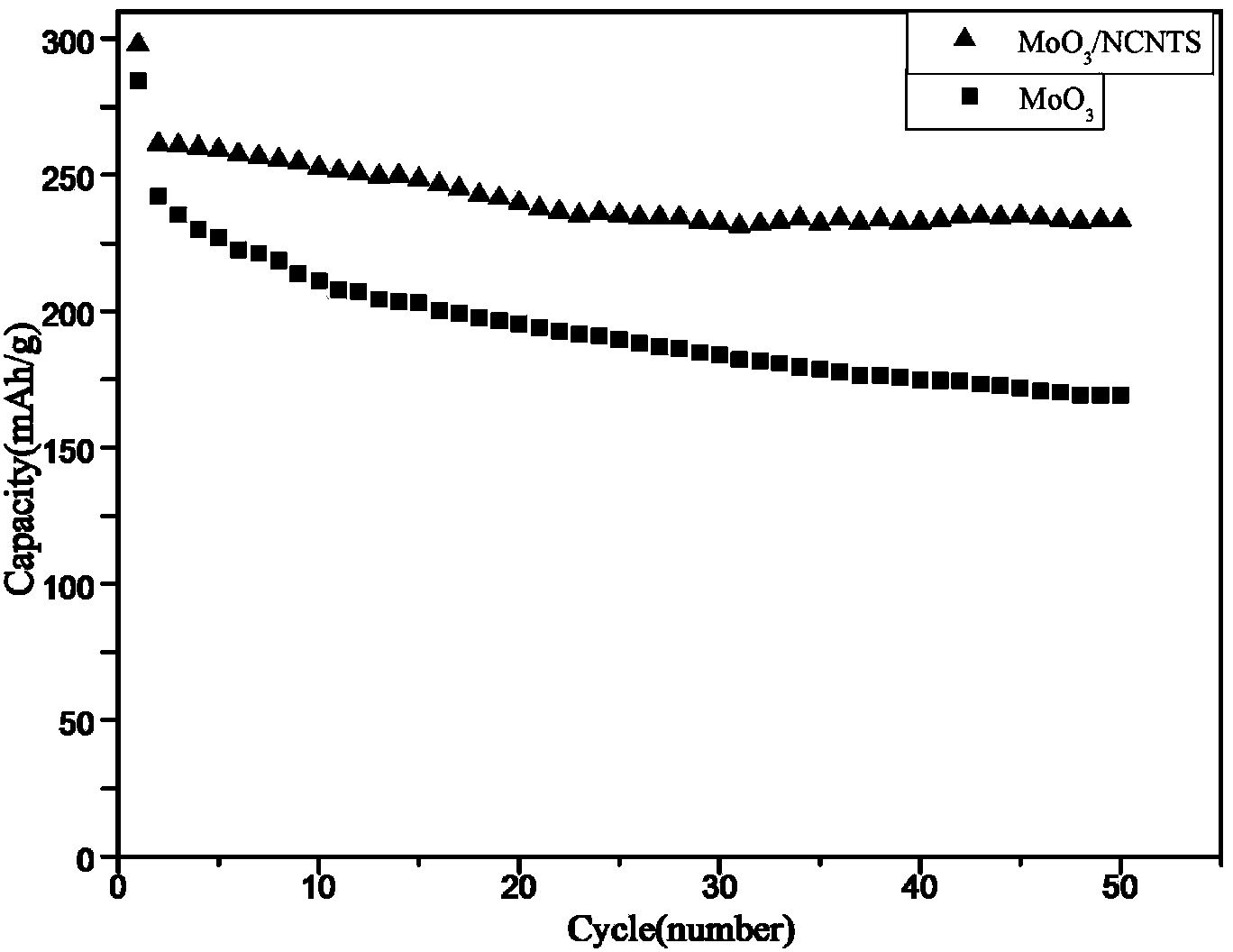

A nanotube composite, molybdenum trioxide technology, applied in the field of electrochemistry, can solve the problems of limited material range and long reaction time, and achieve the effects of improving diffusion capacity, high specific capacity, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Sonicate nickel foam in acetone, wash with distilled water, then sonicate with ethanol, and wash with distilled water.

[0031] (2) Slowly add 4ml of hydrogen peroxide solution with a volume fraction of 30% to 1g of molybdenum powder, and fully react at room temperature. After the exothermic reaction is completed, add 50ml of deionized water to dilute, and then let it stand for 12 hours. Electroplating solution; the nickel foam treated in (1) is used as the working electrode, the platinum sheet electrode is used as the counter electrode, and the silver / silver chloride electrode is used as the reference electrode, and the electrochemical deposition is carried out by constant voltage deposition method (voltage is -0.6V , the deposition time is 120s).

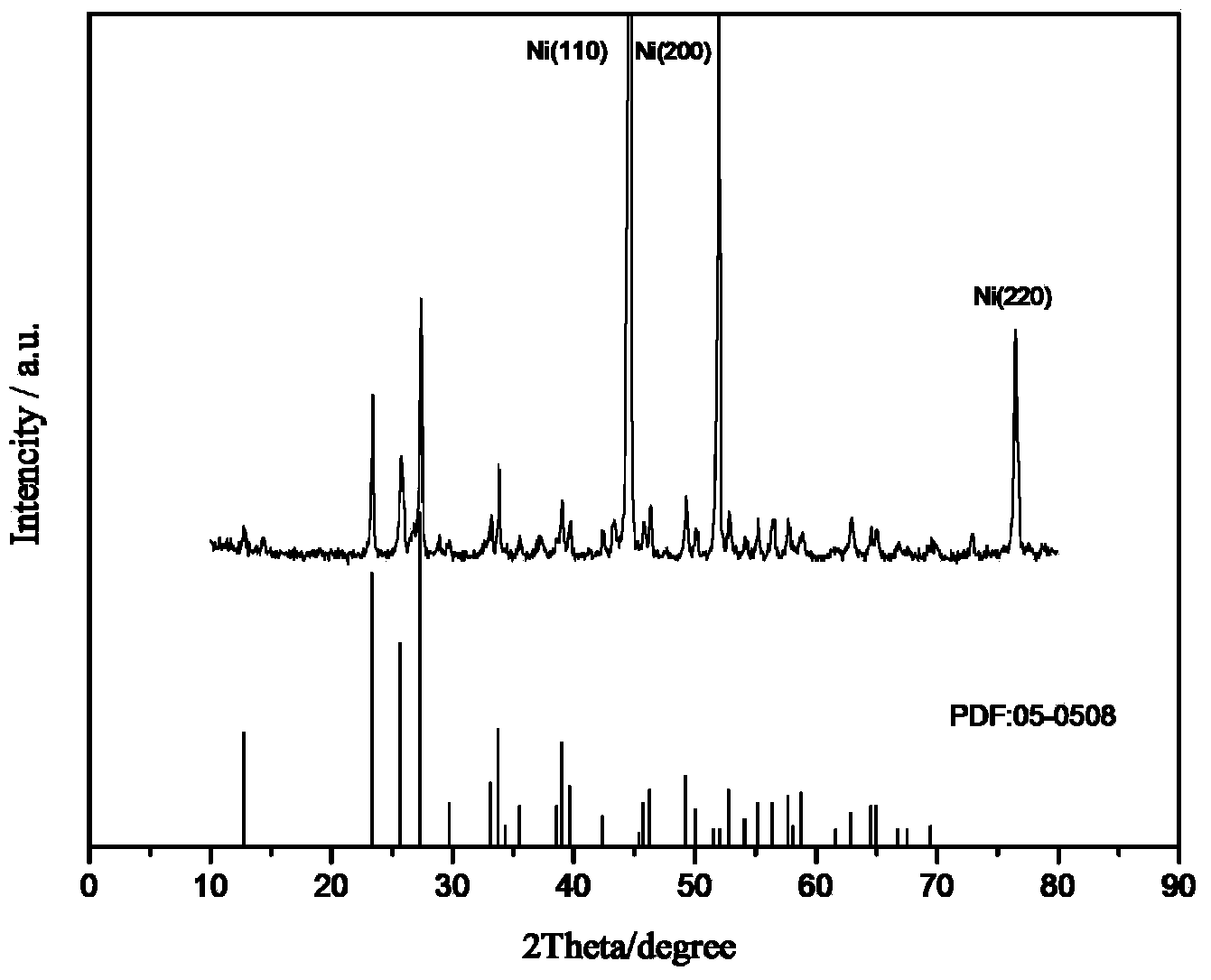

[0032] (3) Anneal the molybdenum compound obtained in (2) at 400° C. for 2 hours in an air atmosphere to obtain molybdenum trioxide on the nickel foam.

[0033] (4) Use the 2032 button battery case as the battery packa...

Embodiment 2

[0035] (1) Weigh 100 mg of ferrocene (analytical pure) and 1 g of melamine (analytical pure), mix them and grind them thoroughly in a mortar until they are evenly mixed.

[0036] (2) Nickel foam is placed in acetone for ultrasonication, washed with distilled water, then ultrasonicated with ethanol, and washed with distilled water.

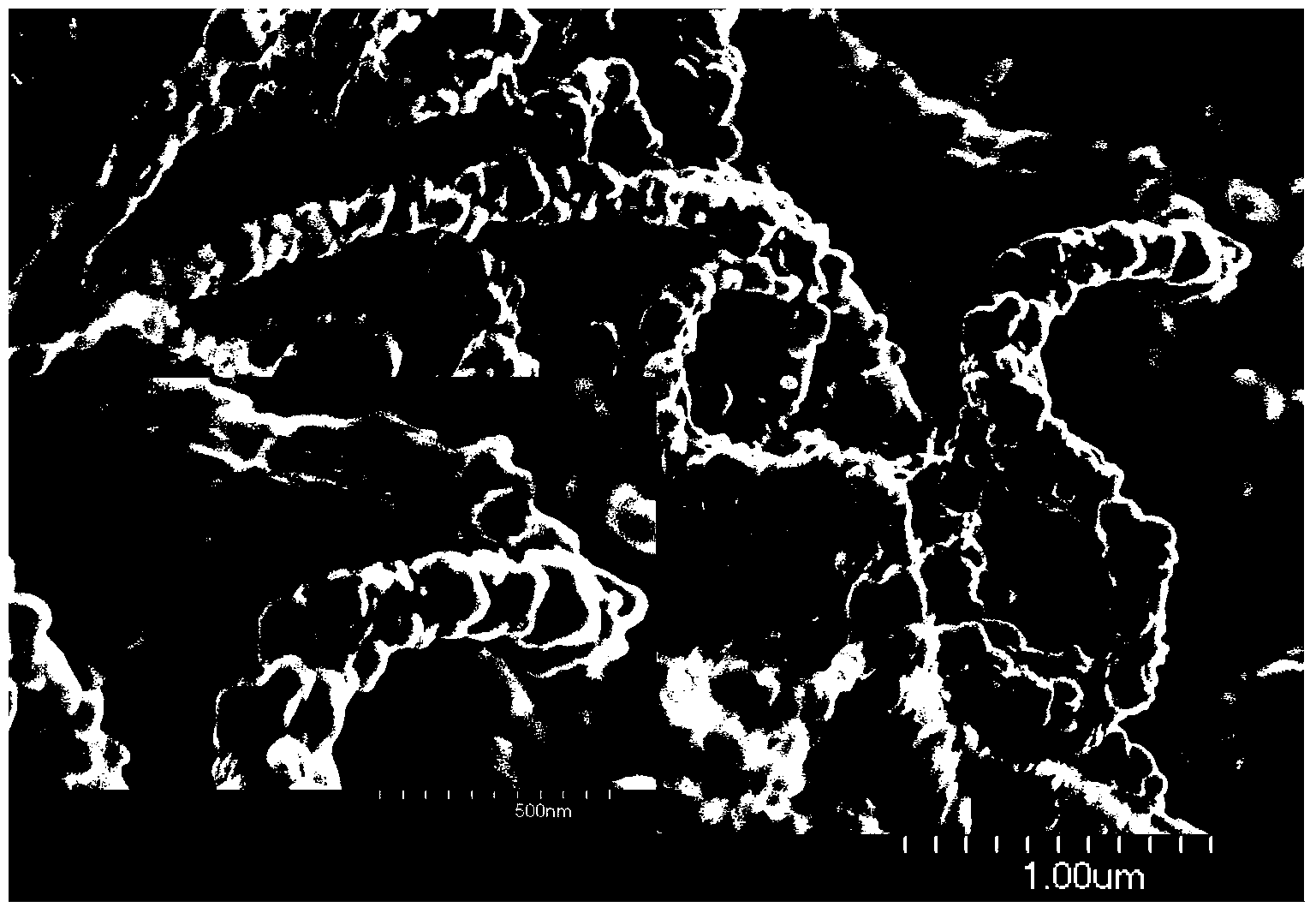

[0037] (3) Put the nickel foam treated in (2) on the stage, put it into the constant temperature zone of the reaction chamber, and pass Ar (80cm 3 / min) as the protective gas and ethylene as the carbon source. After reaching the set temperature of 850°C, slowly add the mixture in (1) into the reaction chamber to obtain a composite structure of nickel foam and nitrogen-doped carbon nanotubes.

[0038] (4) Slowly add 4ml of hydrogen peroxide solution with a volume fraction of 30% to 1g of molybdenum powder, and fully react at room temperature. After the exothermic reaction is completed, add 50ml of deionized water to dilute, and then stand for 12 ho...

Embodiment 3

[0041] (1) Weigh 100 mg of ferrocene (analytical pure) and 1 g of melamine (analytical pure), mix them and grind them thoroughly in a mortar until they are evenly mixed.

[0042] (2) Nickel foam is placed in acetone for ultrasonication, washed with distilled water, then ultrasonicated with ethanol, and washed with distilled water.

[0043] (3) Put the nickel foam treated in (2) on the stage, put it into the constant temperature zone of the reaction chamber, and pass Ar (80cm 3 / min) as the protective gas and ethylene as the carbon source. After reaching the set temperature of 850°C, slowly add the mixture in (1) into the reaction chamber to obtain a composite structure of nickel foam and nitrogen-doped carbon nanotubes.

[0044] (4) Slowly add 4ml of hydrogen peroxide solution with a volume fraction of 30% to 1g of molybdenum powder, and fully react at room temperature. After the exothermic reaction is completed, add 50ml of deionized water to dilute, and then stand for 12 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com