Preparation method of hybrid membrane adsorbent for removing strontium ions in radioactive wastewater

A technology of radioactive wastewater and strontium ions, applied in radioactive purification, chemical instruments and methods, membrane technology, etc., can solve the problems of multiple treatment steps, serious membrane pollution, complicated operation process, etc. Simple, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

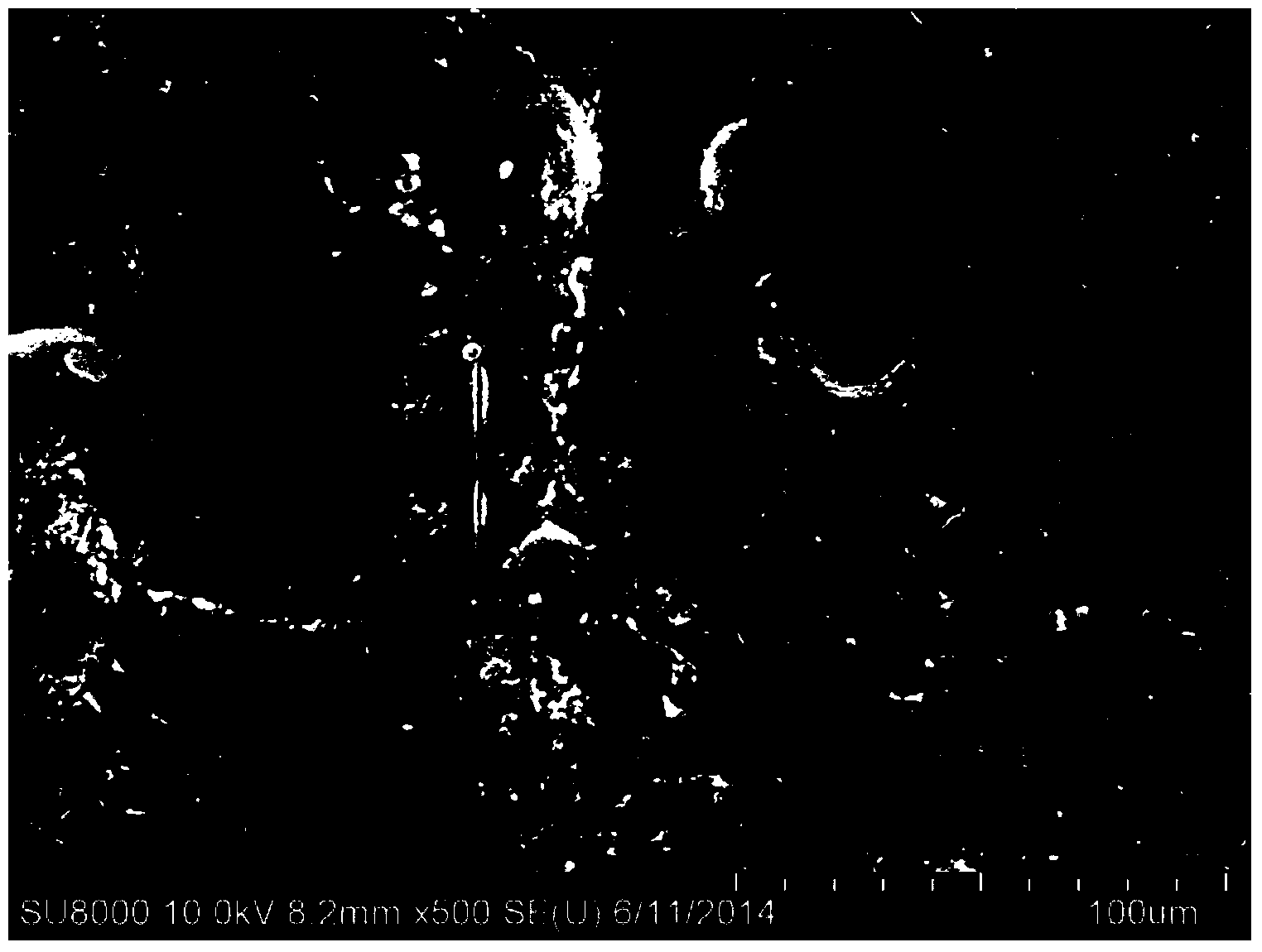

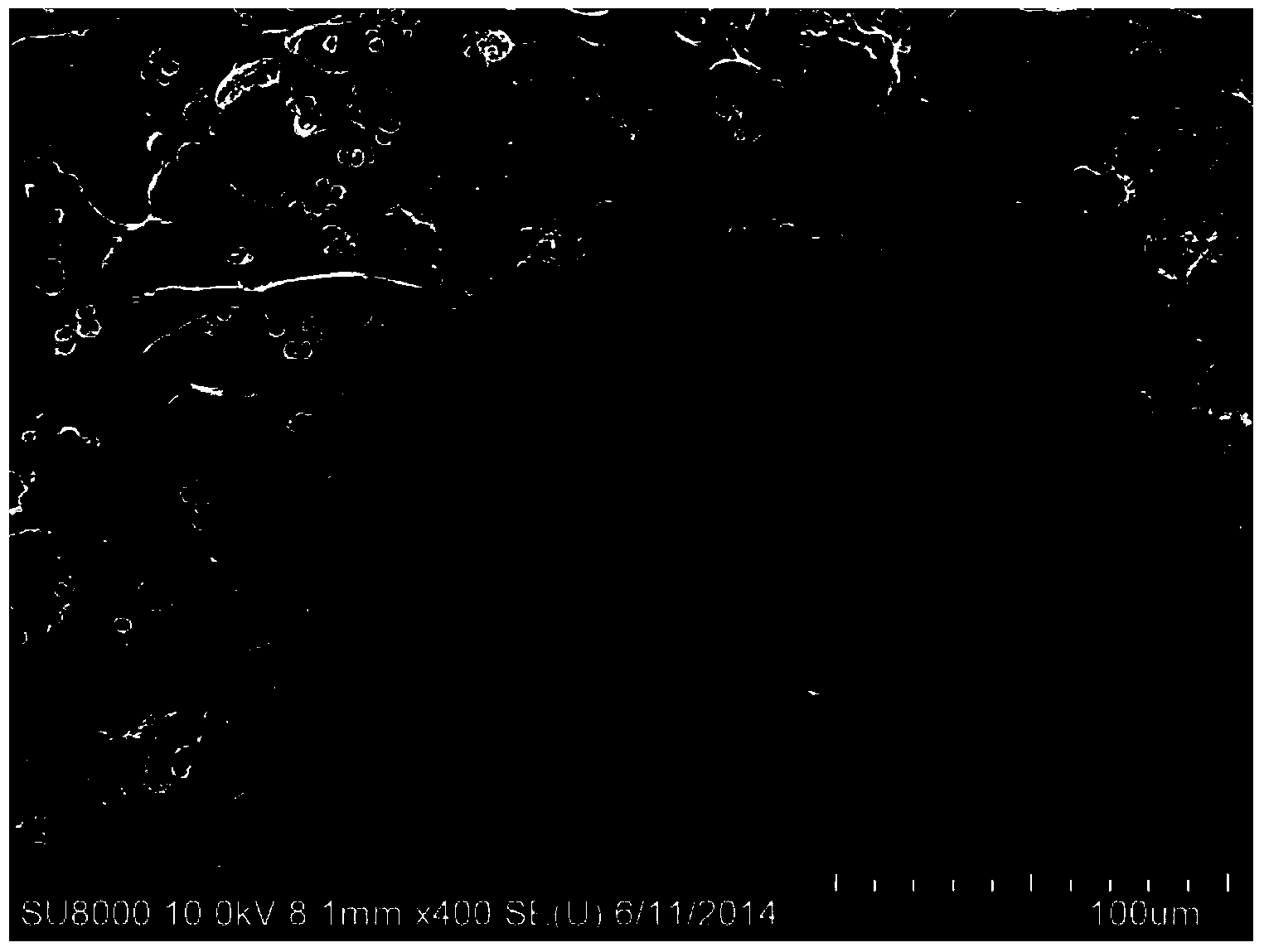

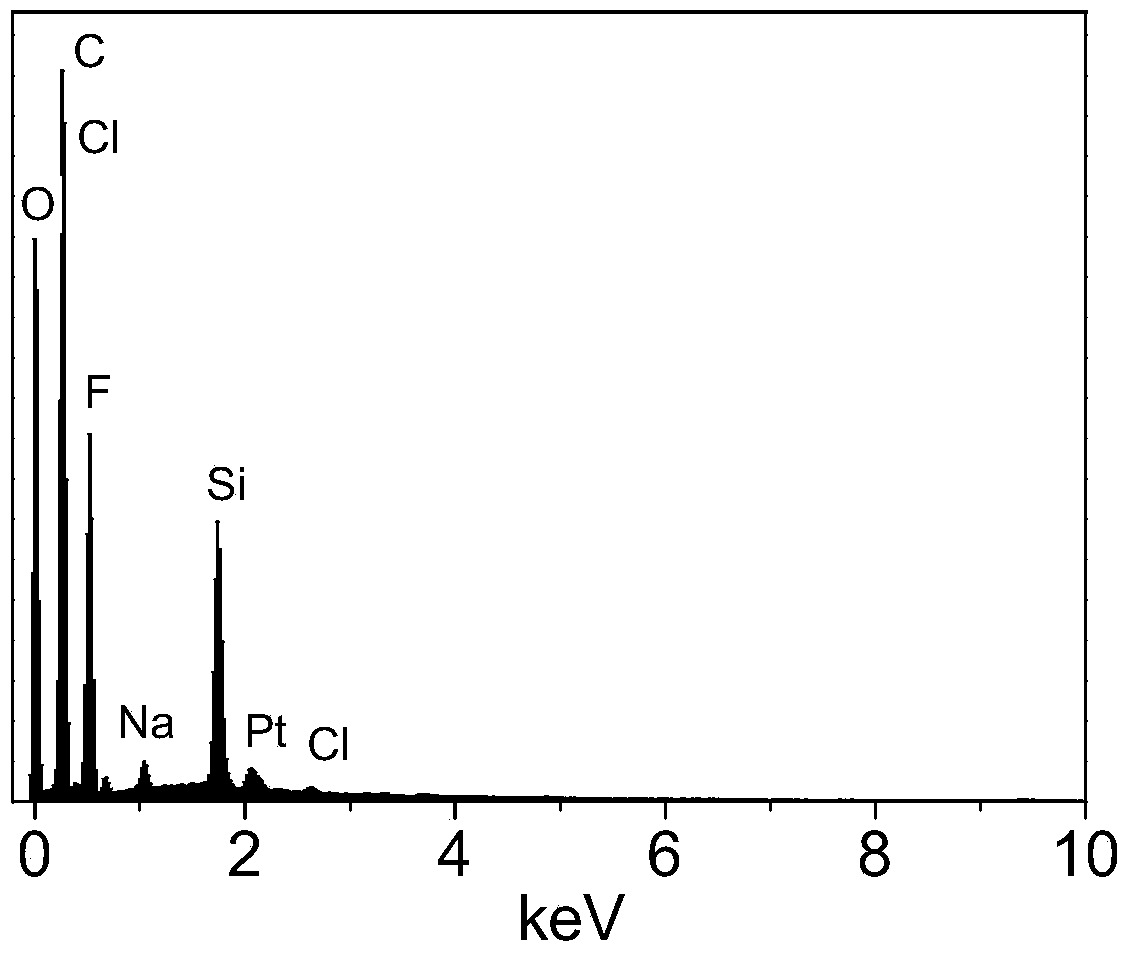

Image

Examples

Embodiment 1

[0024] First, add 25g of polyvinyl alcohol (PVA) with an average degree of polymerization of 1750 ± 50 in a 250mL container equipped with a stirrer, under the temperature condition of 90°C (usually the reaction temperature can be at 0-150°C, it can be selected in this embodiment) Under the temperature condition of 90°C), in an inert atmosphere or air, add deionized water to the container while stirring continuously until the PVA is completely dissolved, and continue stirring for 2h to obtain a solution; then transfer the solution to a 500mL volumetric flask Add deionized water while vibrating to make it uniform, add deionized water until the solution reaches the full 500mL scale of the volumetric flask, continue to vibrate to make it uniform, and thus prepare polyvinyl alcohol with a mass percentage concentration of 5%. (PVA) aqueous solution.

[0025]Extract above-mentioned prepared 5% PVA solution; (calculate the quality of the silane coupling agent that needs to be added by...

Embodiment 2

[0032] Using the same experimental device and operating steps as in Example 1, in an inert atmosphere or air (taken in a nitrogen atmosphere in this embodiment), take 50g of polyvinyl alcohol (PVA) and deionized polyvinyl alcohol (PVA) with an average polymerization degree of 1750 ± 50 Water, the preparation mass percentage concentration is the polyvinyl alcohol (PVA) aqueous solution of 10%. Extract the prepared 10% PVA solution, (according to 0.2 times of the reactant polyvinyl alcohol (PVA) quality, calculate the quality of the silane coupling agent that needs to be added is 10g), add 10g of silane coupling agent γ-ammonia in this solution Propyltriethoxysilane (abbreviated as A-1100), conduct sol-gel reaction at 0°C for 12 hours, and then continue to stir for 24 hours (usually 1-48 hours for sol-gel reaction, in order to make the reaction more complete, this In the embodiment, the sol-gel reaction has been carried out for a total of 36h); the obtained sol-gel reaction prod...

Embodiment 3

[0036] In an argon atmosphere, under the temperature condition of 0°C (usually, the reaction temperature is 0-150°C, and the lower limit of the temperature is 0°C), add 1g to a 250mL container equipped with a stirrer. 50% polyvinyl alcohol (PVA), add deionized water to the container while stirring continuously until the PVA is completely dissolved, continue stirring for 5h to obtain a solution, then transfer the solution to a 1000mL volumetric flask, and shake while adding deionized water Make it uniform until deionized water is added until the solution reaches the full 1000mL scale of the volumetric flask, and continue to shake to make it uniform, thereby preparing a 0.1% mass percent concentration of polyvinyl alcohol (PVA) aqueous solution.

[0037] Extract above-mentioned prepared 0.1% PVA solution, (according to 0.01 times of reactant polyvinyl alcohol (PVA) quality, calculate the quality of the silane coupling agent that needs to add is 0.01g), add 0.01g silane coupling a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com