Manometer magnetofluid and application thereof to purification of pollutants

A nano-magnetic fluid, nano-magnetic material technology, applied in magnetic liquid, oxidized water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve problems affecting catalytic reaction and adsorption reaction application, and achieve high stability, The effect of strong adsorption capacity and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

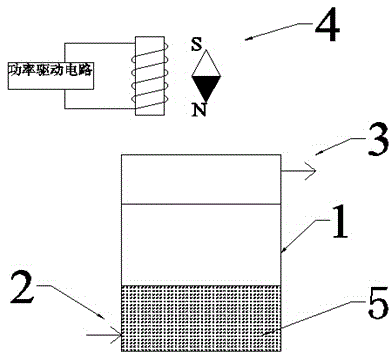

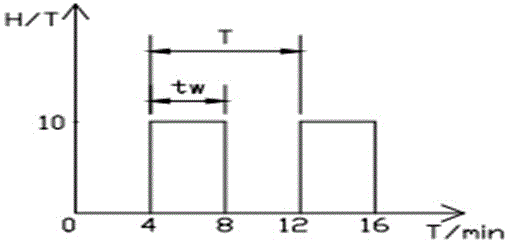

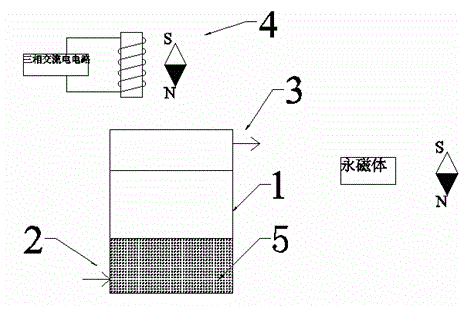

Image

Examples

Embodiment 1

[0043] Example 1: Ben Fe 3 o 4 / TiO 2 The composition and mass percentage of the magnetic fluid is a nano-magnetic material Fe with a core-shell structure 3 o 4 / TiO 2 15%, surfactant sodium oleate 3%, base carrier liquid water 82%.

[0044] The above Fe 3 o 4 / TiO 2 The preparation and application process of ferrofluid is as follows:

[0045] (1) Weigh 1kg of FeCl respectively 2 4H 2 0 and 2 kg FeCl 3 ·6H 2 0, and then add NaOH solution to the mixture of the two, adjust the pH of the mixed solution to 11, stir at a high speed at 50°C for precipitation reaction, and obtain Fe 3 o 4 Particles: Measure OP-10, n-hexanol, cyclohexane and concentrated ammonia water according to the ratio of 1.2:1:1:2.4, mix them to form a microemulsion system, add dilute hydrochloric acid to pickle the treated Fe in sequence under nitrogen protection 3 o 4 Colloidal solution (adjust the pH of the solution to neutral) and butyl titanate, after stirring vigorously for 3 hours, b...

Embodiment 2

[0050] Example 2: This Ni / SiO 2 The composition and mass percentage of the magnetic fluid is a nano-magnetic material Ni / SiO with a core-shell structure 2 20%, surfactant polyethylene glycol (4000) 10%, base carrier liquid water 70%.

[0051] Above Ni / SiO 2 The preparation and application process of ferrofluid is as follows:

[0052] (1) Dissolve 1 kg of nickel chloride in ethylene glycol, prepare a 0.1mol / l nickel chloride solution, and stir magnetically at a constant temperature of 20°C for 10 minutes to obtain solution A; mix NaOH and hydrazine hydrate (n(NaOH):n (NiC1 2 )=1:10, n(N 2 h 4 ):n(NiC1 2 ) = 3:1) dissolved in ethylene glycol to obtain solution B; slowly add solution A to solution B, then add polyvinylpyrrolidone PVP (K-30), stir and put it into a microwave oven, under the action of electric stirring, medium Heat on fire, cool the product, and centrifuge to obtain nano-nickel powder; add Ni powder to ethanol / water mixed solution (volume ratio 1:2), s...

Embodiment 3

[0057] Example 3: The composition and mass percentage of the Fe / Au magnetic fluid are 30% of the core-shell structure nano-magnetic material Fe / Au, 12% of the surfactant sodium oleate, and 58% of the carrier liquid water.

[0058] The preparation and application process of the above-mentioned Fe / Au magnetic fluid are as follows:

[0059] (1) In a reverse micellar system composed of cetyltrimethylammonium bromide (CTAB), n-butanol, n-octane and water, NaBH 4 As a reducing agent, ferrous sulfate and chloroauric acid were successively reduced to generate Fe nuclei in the reverse micellar system, HAuCl 4 The addition of aqueous solution increases the size of the reverse micelles, due to the excess NaBH 4 The presence of Au in the outer layer of Fe is reduced to generate Fe / Au nano-magnetic particles with a core-shell structure. The prepared Fe / Au magnetic nanoparticles are added to the aqueous solution of sodium oleate, stirred for 10 minutes while ultrasonically dispersed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com