A kind of pyrolysis gasoline selective hydrogenation catalyst and its preparation method and application

A technology for selective hydrogenation and pyrolysis of gasoline, applied in the direction of catalyst activation/preparation, selective hydrorefining, chemical instruments and methods, etc., can solve the problem of catalyst hydrogenation stability, many control and influencing factors, and easy coking of pores Problems such as clogging can be avoided, and the effect of easy preparation and production, improved preparation method and good glue capacity can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

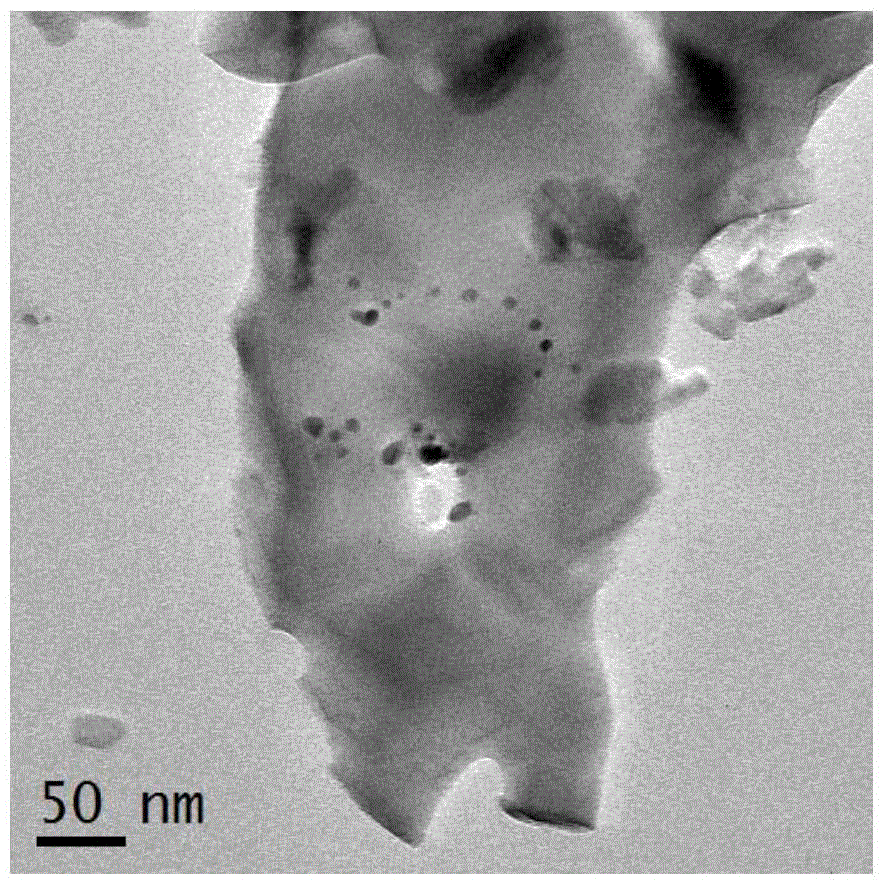

Image

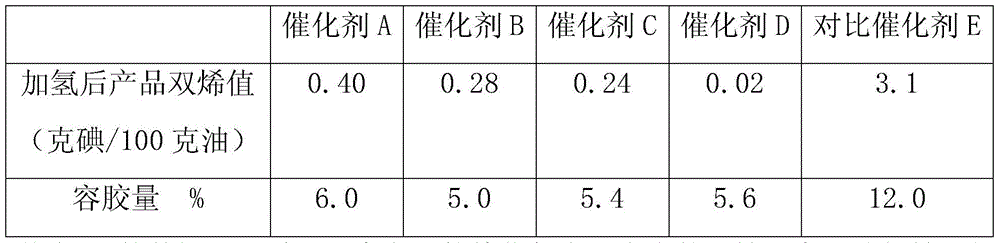

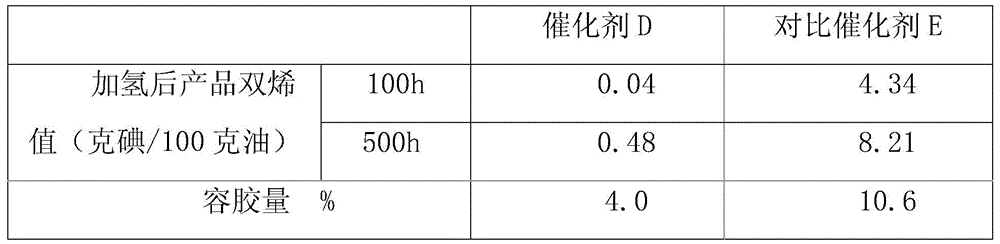

Examples

Embodiment 1

[0037] Pipette 50mgPd / mlPd(NO 3 ) 2 Solution 5ml, weigh 1200mg of polyvinylpyrrolidone (PVP), and dilute to 12g with deionized aqueous solution. Mix 12g Brij35 with 20g cyclohexane in a constant temperature water bath at 65°C under magnetic stirring, then add the prepared PVP and Pd(NO 3 ) 2 Solution, magnetically stirred until a transparent microemulsion is obtained; adding hydrazine hydrate to the above microemulsion to make the Pd(NO in the microemulsion 3 ) 2 Reduced to elemental Pd; weigh 100g Al 2 o 3 Carrier, impregnating the reduced microemulsion onto the carrier. Then dry and calcined to prepare the catalyst A, wherein the Pd content is 0.25wt%.

Embodiment 2

[0039] Weigh 200mgPd / ml of PdCl respectively 2 Solution 1.5ml, 50mgPb / ml PbCl 2 Solution 6ml, weigh polyacrylamide (PAM) 200mg. Dilute to 15g with deionized water, mix 5g AOT with 25g n-octane under magnetic stirring in a constant temperature water bath at 70°C, then add the prepared PAM and metal salt solution, and stir magnetically until a transparent microemulsion is obtained; A certain amount of potassium borohydride hydrate is added to the microemulsion to make the PdCl in the microemulsion 2 and PbCl 2 Reduced to elemental Pd and Pb; weigh 100g SiO 2 Carrier, impregnating the reduced microemulsion onto the carrier. Then dry and roast to prepare the catalyst B, wherein the Pd content is 0.3wt%, and the Pb content is 0.3wt%.

Embodiment 3

[0041] Weigh out 200mgPd / ml of Pd(NO 3 ) 2 Solution 1.25ml, 200mgPb / ml of Pb(NO 3 ) 2 Solution 2.5ml, mixed, then weighed 10.55g Mg(NO 3 ) 2 ·6H 2 O and weigh 100 mg of hydroxymethyl cellulose and put it into the aqueous solution of Pd and Pb. Dilute to 20g with deionized water, mix 10g Brij30 and 8g AOT with 22g n-butane in a constant temperature water bath at 40°C under magnetic stirring, then add the prepared hydroxymethylcellulose and metal salt solution, and magnetically stir until A transparent microemulsion is obtained; a certain amount of hydrazine hydrate is added to the above microemulsion to reduce the metal salt solution in the microemulsion to an elemental state. Weigh 100g Al 2 o 3 Carrier, the reduced microemulsion is sprayed onto the carrier, then dried and roasted to prepare the catalyst C, wherein the Pd content is 0.25wt%, the Pb content is 0.50wt%, and the Mg content is 1.0wt% of the total mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com