Waste gas dust removing method and dust removing agent

一种有机除尘剂、废气的技术,应用在分离方法、化学仪器和方法、液体脱气等方向,能够解决不具有去除重金属化合物等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

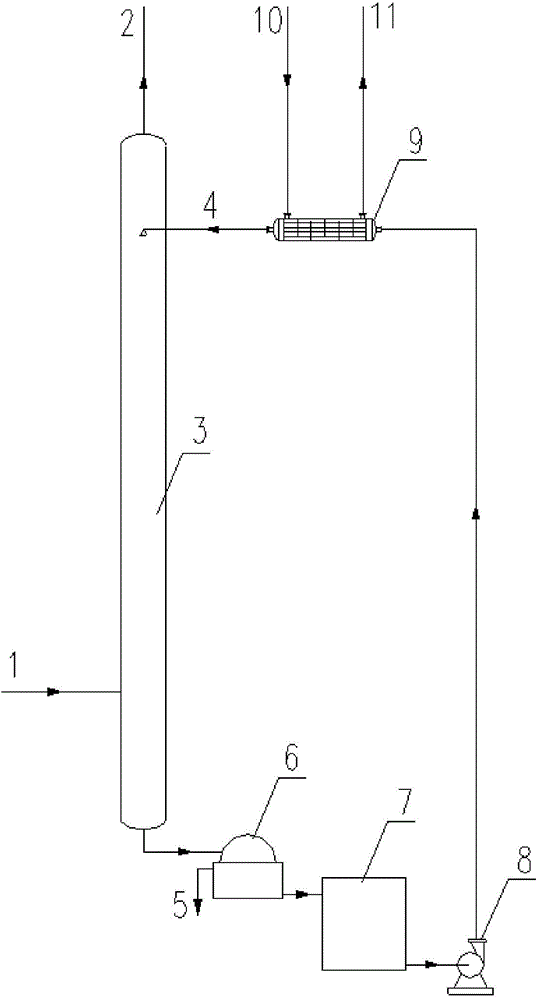

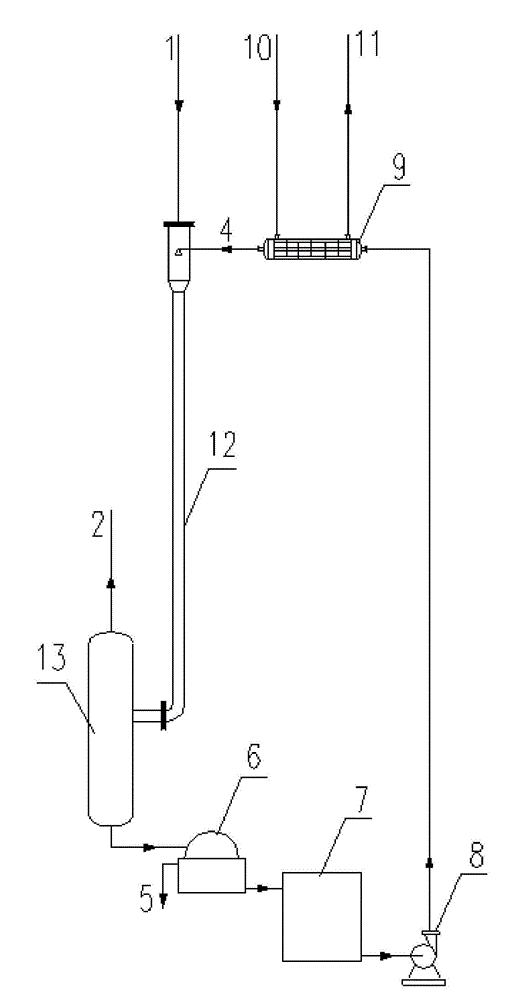

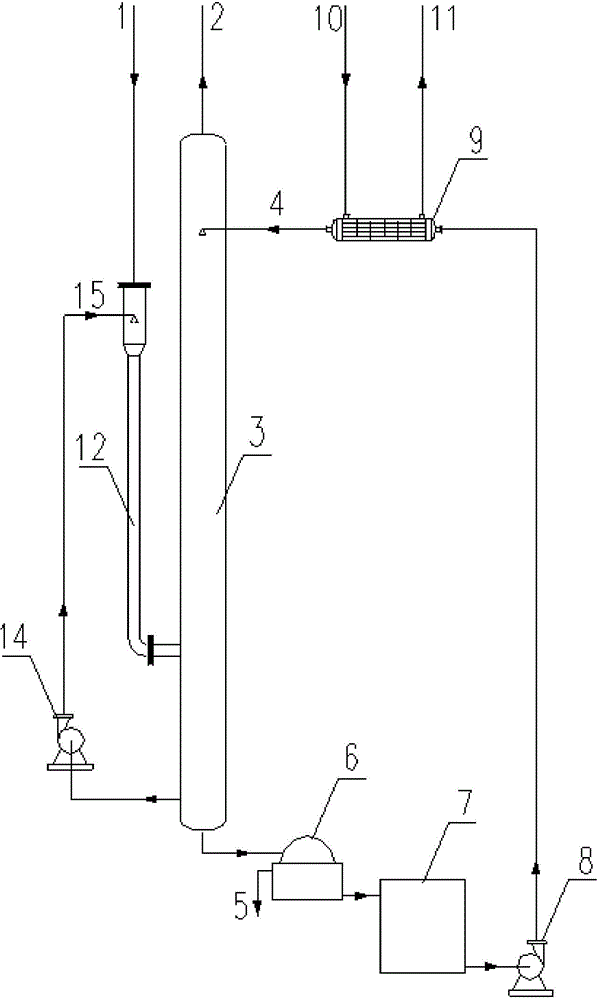

Method used

Image

Examples

Embodiment 1

[0058] Example 1 The absorption bottle used in the laboratory is used, and 200ml of modified silicone oil is filled in the absorption bottle, and the exhaust gas of a kiln that uses petroleum coke as raw material to produce 800 tons of glass per day is directly collected from a kiln exhaust gas of a group in Huzhou, Zhejiang, and is dedusted by a bag filter. On the final pipeline, exhaust gas was extracted for dust removal test; 1Nm 3 The exhaust gas passes through the absorption bottle and is absorbed by the 200ml modified silicone oil in the absorption bottle; the 200ml modified silicone oil that has absorbed the dust is subjected to centrifugal separation. Then there is the water layer, then the solid organic layer, and the top layer is the modified silicone oil layer; after drying and weighing, the weight of the ash layer is 2.3546g, and the weight of the solid organic layer is 0.3213g, so the glass kiln after bag dust removal The content of dust and organic matter in the ...

Embodiment 2

[0059] Embodiment 2 adopts the absorption bottle used in the laboratory, and puts 200ml of peanut oil and modified silicone oil mixture into the absorption bottle, directly from a kiln tail gas of a group in Hainan that uses natural gas as raw material to produce 600 tons of glass per day, after denitrification and On the pipeline after alkaline desulfurization, exhaust gas was extracted for dust removal test; 0.6Nm 3 The exhaust gas passes through the absorption bottle and is absorbed by the 200ml mixture of peanut oil and modified silicone oil in the absorption bottle; the 200ml mixture of peanut oil and modified silicone oil that has absorbed dust is subjected to centrifugation, and after centrifugation, it is divided into three layers in the centrifuge tube : The bottom is the ash layer, followed by the water layer, and the uppermost layer is the mixed liquid layer of peanut oil and modified silicone oil; the weight of the ash layer after drying and weighing is 0.5347g, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com