Application of modified resin in process of boron removal

A modified resin and removal technology, applied in the direction of adsorption water/sewage treatment, etc., can solve the problems of resin stability acid pollution, resin service life reduction, etc., achieve low equipment requirements, improve service life, and good boron removal ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

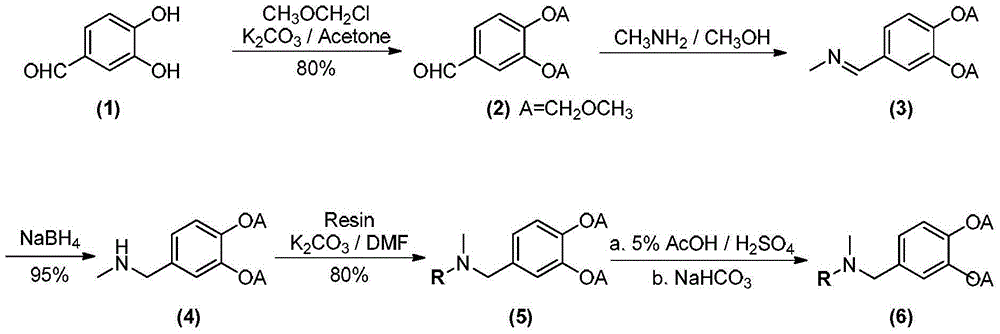

[0019] Embodiment 1: hydroxyl protection reaction

[0020]

[0021] Add 3,4-dinitrobenzaldehyde in a round bottom flask, dissolve in acetone, add chloromethyl methyl ether and potassium carbonate, protect with argon, react at room temperature for 17h, filter under reduced pressure, wash with ethyl acetate , collect the filtrate, steam it, pass through the column, collect the main product (white solid), evaporate it by rotary steam, and set aside.

Embodiment 2

[0022] Embodiment 2: side chain synthesis reaction

[0023]

[0024] Add methylamine to the product in Example 1, stir and react at room temperature for 15 minutes, add sodium borohydride several times in small amounts under ice bath, remove the ice bath, stir and react at room temperature for 1 hour, add distilled water, and distill to remove methanol, dichloro Extracted with methane, dried the organic phase with anhydrous sodium sulfate, filtered, and the filtrate was rotary evaporated, and the product (yellow oil) was set aside.

Embodiment 3

[0025] Embodiment 3: Resin linkage reaction

[0026]

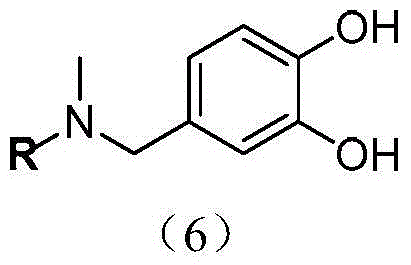

[0027] Dissolve the product in Example 2 in dimethyl sulfoxide, add resin (Merrifield resin, model G20M1254) and potassium carbonate, react under argon protection at 50°C for 17 hours, filter under reduced pressure, and wash with distilled water and methanol successively Filter cake, collect the filter cake and suspend it in 5% acetic acid (containing sulfuric acid, the molar ratio of compound (4) to sulfuric acid is 10:1) solution, reflux and boil for 15min, cool to room temperature, filter under reduced pressure, and wash the filter cake with distilled water until Neutral, suspend in saturated sodium bicarbonate solution, stir magnetically for 1 hour, filter under reduced pressure, wash the filter cake with distilled water until neutral, rinse the filter cake with methanol, and obtain the modified resin product (6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com