Microcapsule graphene composite material controlled-release pesticide-fertilizer granules and preparation method

A composite material, graphene technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of less than one fertilization, slow release, etc., to extend the application cycle, improve biological activity, and solve the problem of fertilizer use and pests and diseases Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

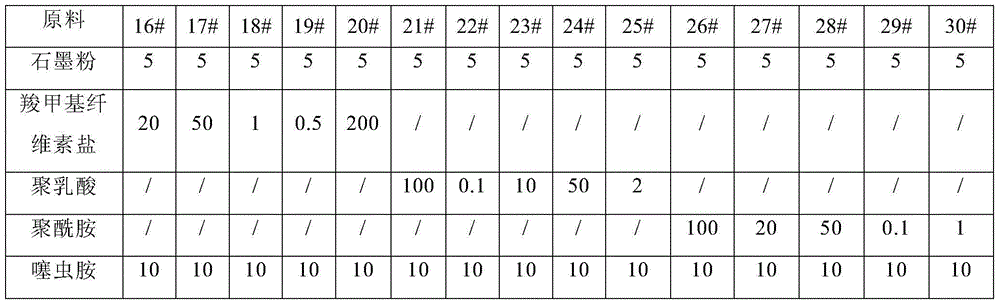

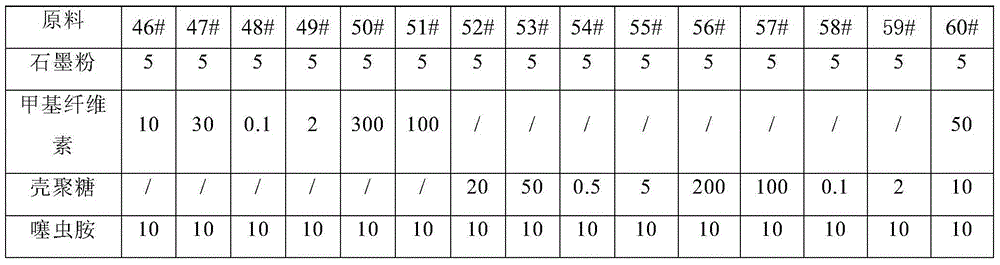

[0033] The preparation method of the above-mentioned parent powder sample is as follows: after clothianidin and graphite powder are fully mixed, they are pulverized by air flow to obtain medicinal powder A; medicinal powder A, polymer compound liquid medium and grinding balls are placed in a ball mill, and mechanically ground. A mixed suspension is obtained; the above mixed suspension is coagulated to obtain a mixture of the microcapsule graphene composite material and the active ingredient of the pesticide, and the mother powder is obtained after drying.

[0034] The preparation method of the above-mentioned control sample is as follows: after fully mixing clothianidin with graphene oxide or chitosan, they are crushed by air flow.

[0035] This experiment also set clothianidin as the control 66#.

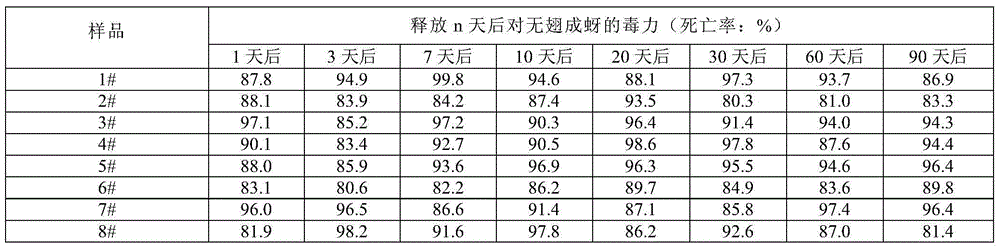

[0036] 2. Test methods and results

[0037] Take the above 60 parent powder samples and 6 control samples with the same amount of clothianidin active ingredient, mix them with the...

preparation Embodiment 1

[0047] (1) Take 10 kg of monosultap, 1 kg of pymetrozine, 1 kg of azoxystrobin, and 20 kg of graphite powder, mix them thoroughly, and pulverize them by air flow to obtain powder A.

[0048](2) Place medicated powder A, chitosan liquid medium, and grinding balls in a ball mill, and perform mechanical grinding to obtain a mixed suspension; the above-mentioned mixed suspension is passed through the coagulation method to obtain microcapsule graphene composite materials and pesticide active ingredients The mixture, after drying, the mother powder is obtained;

[0049] (3) Preparation of medicinal fertilizer granules (take the production of 1000Kg as an example): take urea 300Kg, ammonium sulfate 100Kg, monoammonium 150Kg, potassium chloride 200Kg, borax 10Kg, sugarcane filter mud 100kg, potassium fulvic acid 2.5kg, the above mother Powder 20Kg, make up with kaolin, add in the drum granulator to granulate, dry, and finally the toluene solution of epoxy resin is sprayed on the above...

preparation Embodiment 3

[0055] (1) Take 1kg of fipronil, 0.75kg of nitenpyram, 3Kg of tricyclazole, 0.6Kg of thifluxamide, and 20kg of graphite powder, mix them well, and then pulverize them by air flow to obtain powder A.

[0056] (2) medicine powder A, methyl cellulose liquid medium, and grinding ball are placed in ball mill, carry out mechanical grinding, obtain mixed suspension; The above-mentioned mixed suspension is passed through the method of agglomeration, obtains microcapsule graphene composite material and pesticide effective The mixture of ingredients, after drying, the mother powder is obtained;

[0057] (3) Preparation of medicinal fertilizer granules (taking the production of 1000Kg as an example): get urea 300Kg, superphosphate 200Kg, potassium chloride 200Kg, calcium magnesium phosphate fertilizer 200Kg, borax 10Kg, sugarcane filter mud 100kg, potassium fulvic acid 2.5kg, 8kg of osthole, 20Kg of the above-mentioned parent powder, supplemented by attapulgite, add to the drum granulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com