Method and device for recycling and harmlessly treating waste lithium ion battery electrolyte

A lithium-ion battery, harmless treatment technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve problems such as complex recycling process, achieve process efficiency, optimize resource allocation, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

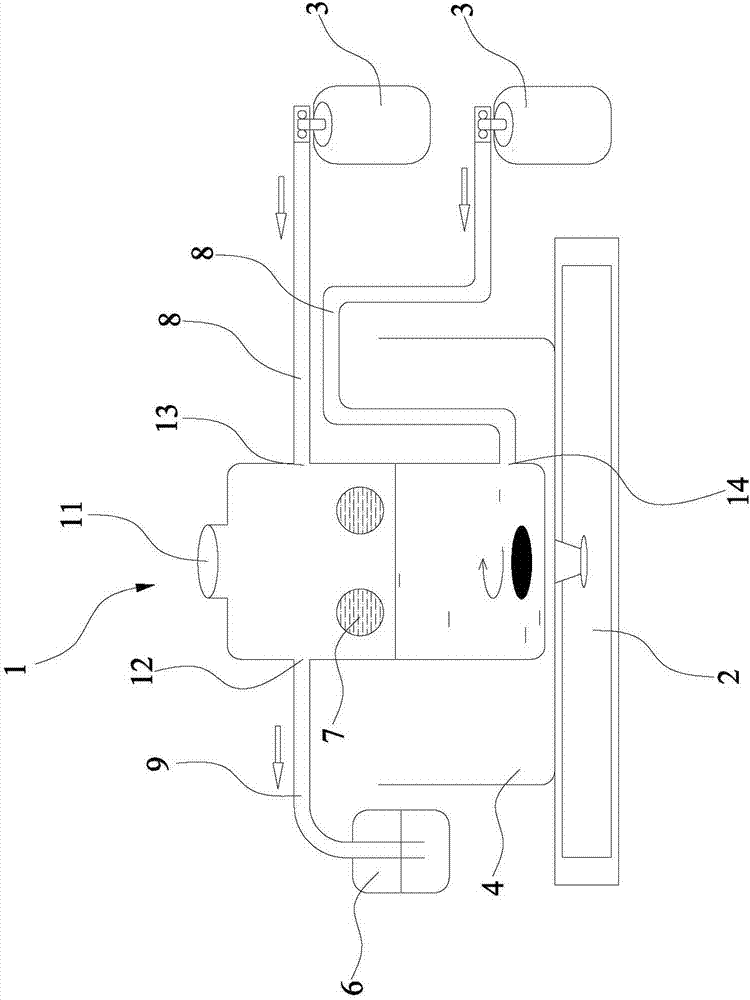

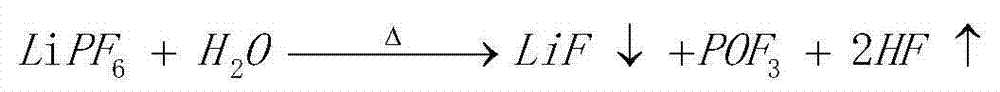

Embodiment 1

[0040] Embodiment 1: Clean the waste lithium-ion battery and perform a complete discharge treatment. Mechanically open the steel shell of the battery, take out the battery cell, immerse 14 grams of the battery cell in the reaction cell 1 filled with propylene carbonate solution, and the user mechanically disassembles the battery cell through rubber heat-insulating gloves 7 to obtain the aluminum foil and its surface Attached positive electrode material, copper foil, carbon powder, separator, etc. attached to its surface. Lithium hexafluorophosphate is dissolved in the propylene carbonate solution in reaction tank 1, and the aluminum foil (coated with positive electrode material), copper foil (coated with negative electrode material) and diaphragm can be directly taken out for corresponding recycling.

[0041] The reaction tank 1 that propylene carbonate solution is housed is put on the magnetic heating stirrer 2 and carries out water bath heating, and reaction temperature is 9...

Embodiment 2

[0044] Embodiment 2: The difference from Embodiment 1 is that the cell is immersed in the reaction cell 1 containing ethylene carbonate solution, the reaction temperature is 80°C, the stirring speed is 300r / min, the reaction time is 3 hours, and the inert gas It is nitrogen, and in the suction device 6 is potassium hydroxide absorption liquid.

Embodiment 3

[0045] Embodiment 3: The difference from Embodiment 1 is that 50 grams of batteries are immersed in the reaction tank 1 equipped with ethylene glycol diethyl ether solution, the reaction temperature is 70 ° C, the added quality of lithium phosphate is 0.7 grams, and the stirring speed is The reaction time is 200r / min, the reaction time is 6 hours, the inert gas is helium, and the hydrogen fluoride produced in the reaction is absorbed by the lithium hydroxide absorption solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com