Zinc oxide-based transparent conductive film

A transparent conductive film, zinc oxide technology, applied in the conductive layer, circuit, photovoltaic power generation and other directions on the insulating carrier, to achieve the effect of high conversion efficiency, excellent transmittance and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

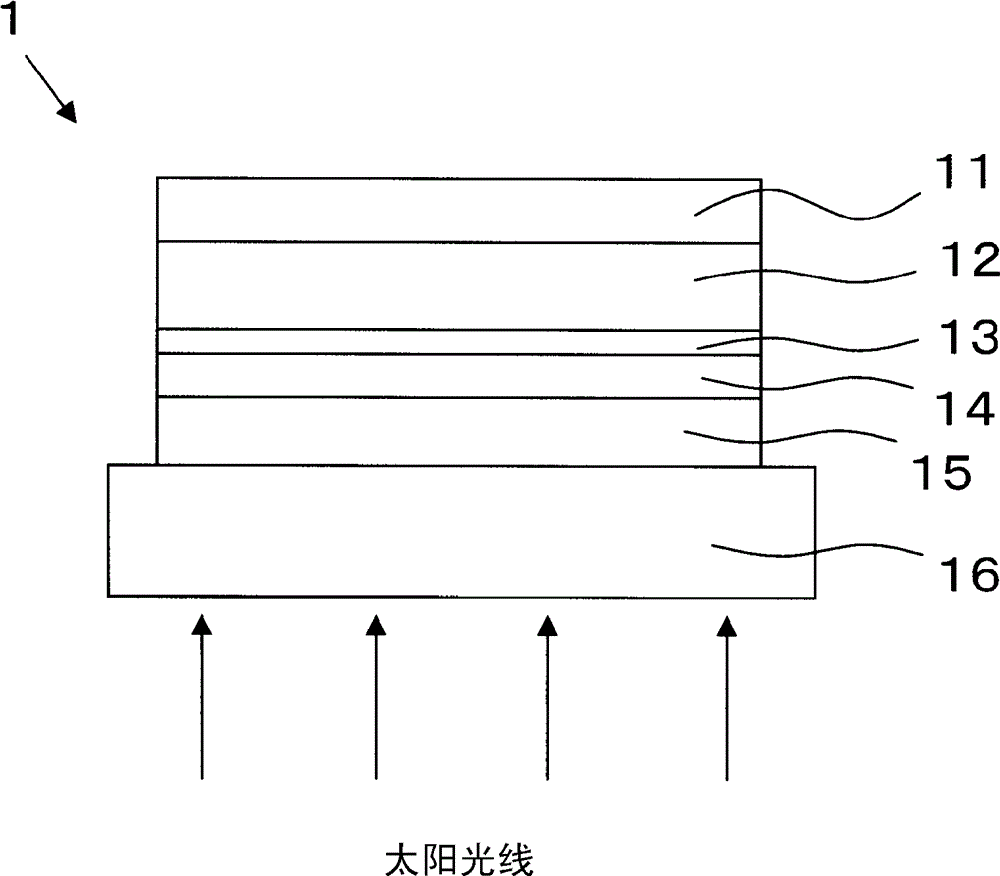

[0177] Examples of the material of the p layer include hydrogenated amorphous silicon carbide (a-SiC:H).

[0178] Examples of materials for the i layer include hydrogenated amorphous silicon (a-Si: H), crystalline silicon (c-Si), microcrystalline silicon (μc-Si), and hydrogenated amorphous silicon germanium (a-SiGe: H). . Among these, hydrogenated amorphous silicon (a-Si:H) is preferable.

[0179] In addition, examples of n-layer materials include hydrogenated amorphous silicon (a-Si:H) and microcrystalline silicon (μc-Si). Among these, hydrogenated amorphous silicon (a-Si:H) is preferable.

[0180] As another example, it is preferable to use an electrifying layer having a tandem structure in which another p-i-n layer is further formed on the p-i-n layer of a-Si. More preferably, on the layer formed on the p-i-n layer of amorphous silicon (a-Si), an a-Si:H layer as the p layer, a microcrystalline Si layer as the i layer, and a Three layers of a-Si: H layer, or a tandem str...

Embodiment 1)

[0216] Zinc oxide powder (ZnO: manufactured by Hakusitec Co., Ltd., purity 99.9%, average primary particle size 1 μm or less) and titanium monoxide powder (TiO(II): Furuuchi Chemical Co., Ltd., purity 99.9%, average primary particle size 1 μm or less) were mixed with A total of 100 g was weighed so that the atomic number ratio of zinc and titanium became Zn:Ti=98.2:1.8, and it was put into a resin bottle. Next, 50 g of ethanol was injected as a solvent, and wet mixing was performed by a wet ball mill mixing method. In this wet mixing, hard ZrO is used as balls 2 Ball (2mmφ), for 18 hours. Next, the slurry after wet mixing was taken out, the balls were removed by a sieve, the mixed solvent was removed by a rotary evaporator, and the residue was dried at 100° C. for 3 hours with a hot air dryer to obtain a mixed powder.

[0217] The obtained mixed powder was put into a mold (mold) made of graphite with a diameter of 100 mm. Vacuum pressurization was performed at a pressure of...

Embodiment 2)

[0238] Zinc oxide powder and titanium monoxide powder were used in the same manner as in Example 1 so that the composition of the raw materials shown in Table 1 was obtained, and as the alumina powder, Sumitomo Chemical Co., Ltd. containing 99.9% purity and an average primary particle size of 0.5 μm Al made by the company 2 o 3 A sputtering target was obtained in the same procedure as in Example 1 except for the raw material powder of the powder.

[0239] Using the obtained sputtering target, a zinc oxide-based transparent conductive film was formed on the substrate to have a film thickness of about 500 nm by the sputtering method under the same conditions as in Example 1.

[0240] In the case of using any sputtering target, within about 50 minutes of sputtering, the number of times the sputtering device stops operating due to abnormal discharge is less than 3 times, the sputtering rate is about 10nm / min, and the film formation stability good.

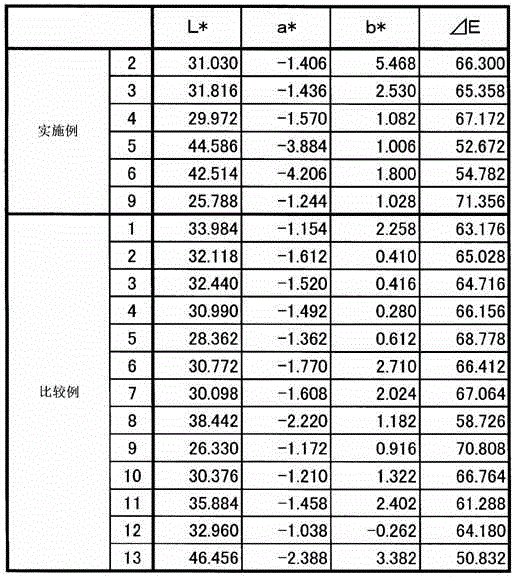

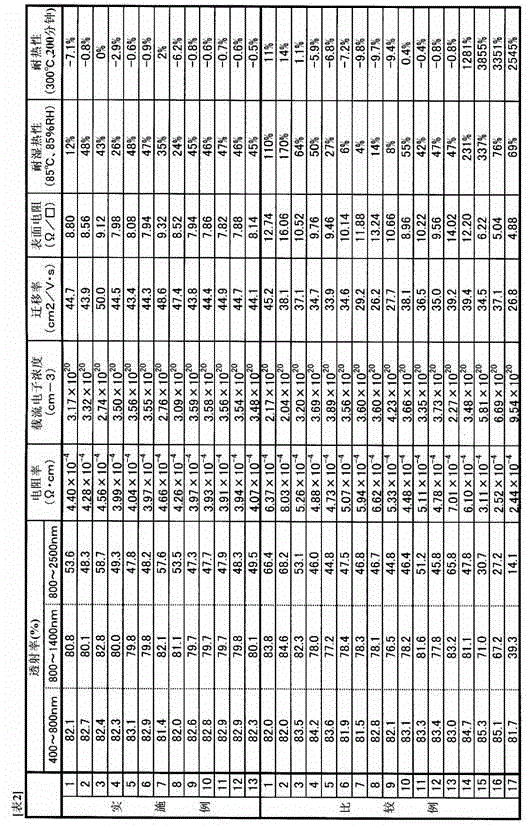

[0241] For each obtained thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com