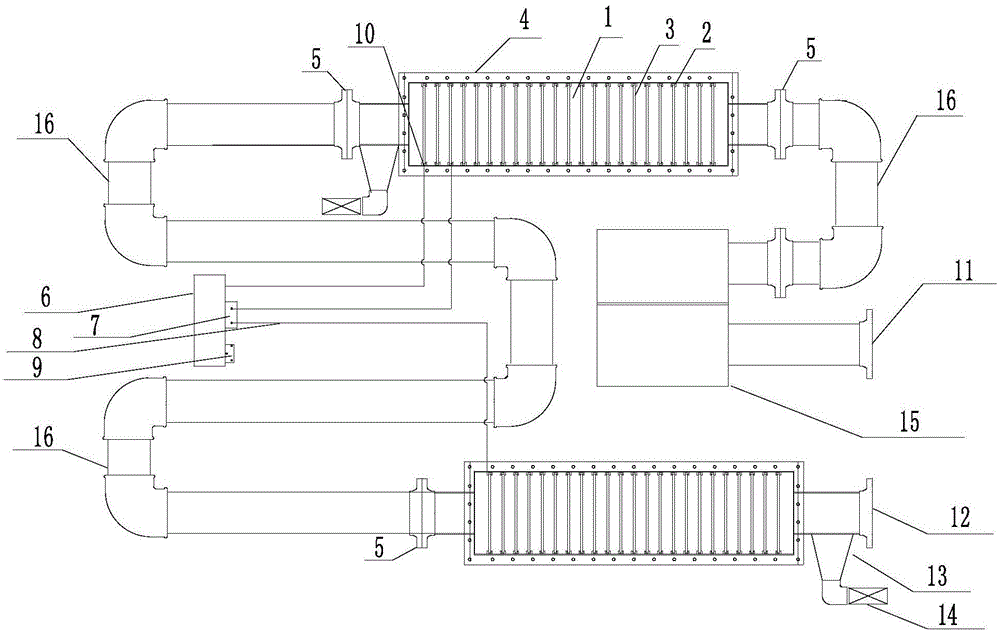

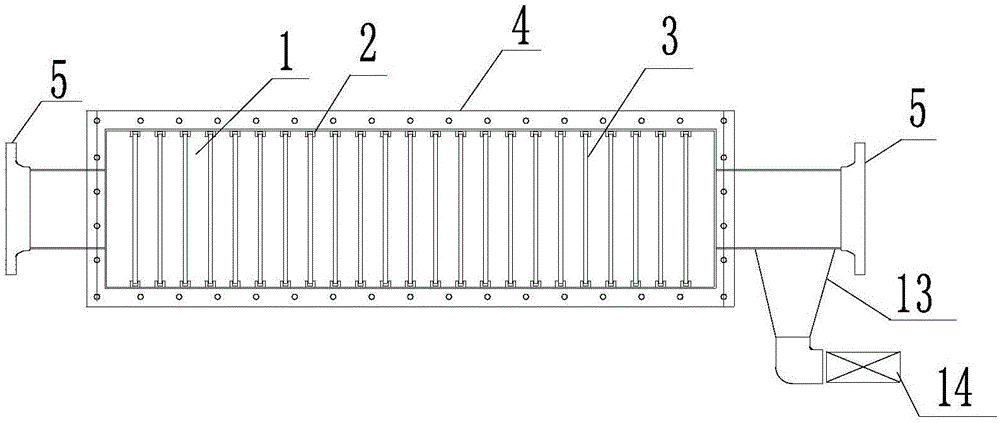

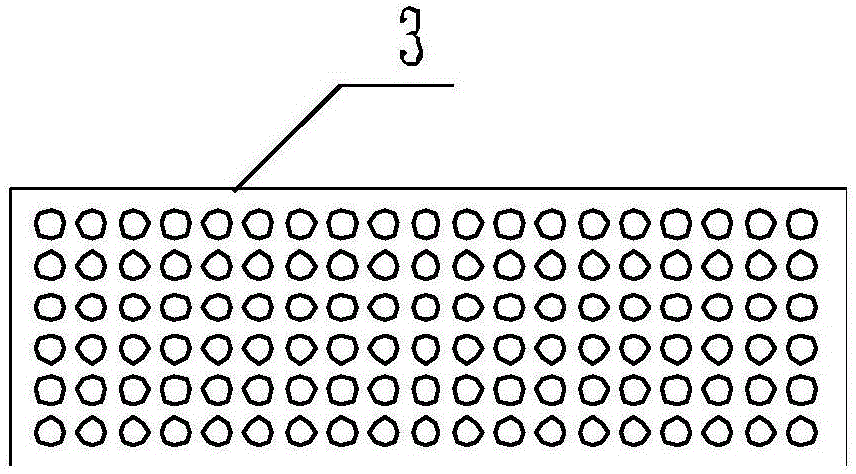

Biochemical system auxiliary device and application thereof

A technology for auxiliary equipment and biochemical systems, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as no feasibility, many links, and few applications, and achieve Effects of increasing biodegradability, improving anaerobic efficiency, and eliminating toxic accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A pesticide preparation company treated 30m of pesticide preparation tank sewage 3

[0069] Using the auxiliary equipment (goldscull) for efficient and stable operation of the biochemical system, adjust the voltage to 300v, the working mode is commutation pulse output, the frequency is 40Hz, the running time is 90s, the intermittent time is 10s, the display current is 0.1A, after 208 Hours of operation, COD dropped from 6400mg / L to 3333mg / L, and the removal rate was 48%. The invention is cost-effective in terms of pretreatment disinfection and increased biodegradability.

Embodiment 2

[0071] Biochemical sludge of a pesticide factory: 100m 3 ,

[0072] Use the biochemical system to efficiently and stably run the auxiliary equipment (goldscull), adjust the voltage to 300v, the working mode is square wave pulse output, the frequency is 28Hz, the running time is 60s, the intermittent time is 30s, and the display current is 0.15A

[0073] After 48 hours of operation, COD dropped from 26750mg / L to 4480mg / L, with a removal rate of 83%; ammonia nitrogen dropped from 765mg / L to 145mg / L, with a removal rate of 78.5%. Power consumption of 1.44kw.h removes 2227kg of COD, which shows that the solution of the present invention is extremely cost-effective in degrading COD.

Embodiment 3

[0075] A pesticide high concentration wastewater 100m 3 :

[0076] Use the biochemical system to efficiently and stably run the auxiliary equipment (goldscull), adjust the voltage to 300v, the working mode is commutation pulse output, the frequency is 40Hz, the running time is 90s, the intermittent time is 10s, and the display current is 0.15A:

[0077] After many tests, the COD, ammonia nitrogen, Kjeldahl nitrogen, and total nitrogen have obvious downward trends, and the technical scheme of the application is effective in disinfection, catalytic oxidation and decomposition of complex organic matter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com