High-transparency high-temperature-resistance polylactic acid composite material and preparation method thereof

A composite material and polylactic acid technology, which are applied in the field of high-transparency and high-temperature-resistant polylactic acid composite materials and their preparation, can solve the problems that do not involve improving the temperature resistance and hydrolysis stability of polylactic acid, the crystallization time is too long, and the transparency is poor. Improved hydrolysis stability, simple and easy preparation method, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

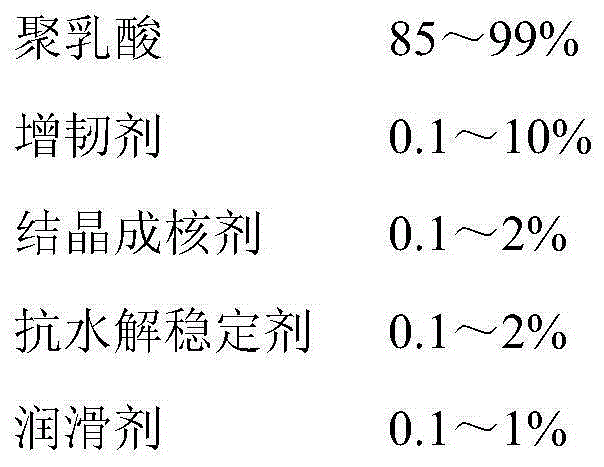

[0037] Each component of raw material is as follows in the embodiment:

[0038] Polylactic acid: Naturworks produces grades of 3052D polylactic acid has a D-lactic acid content of 0.5% and a number average molecular weight of 150,000. Of course, we can also choose other brands or polylactic acid from other manufacturers.

[0039] The molar ratio of vinyl acetate monomer to vinyl laurate monomer in vinyl acetate-vinyl laurate copolymer is 1:1.5, and the molecular weight is 30,000.

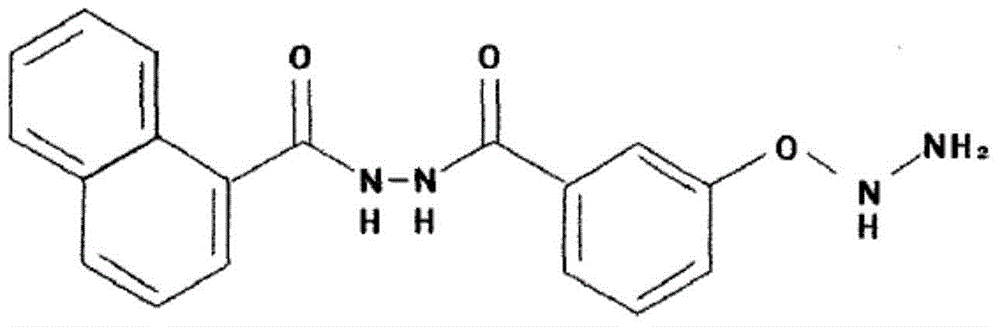

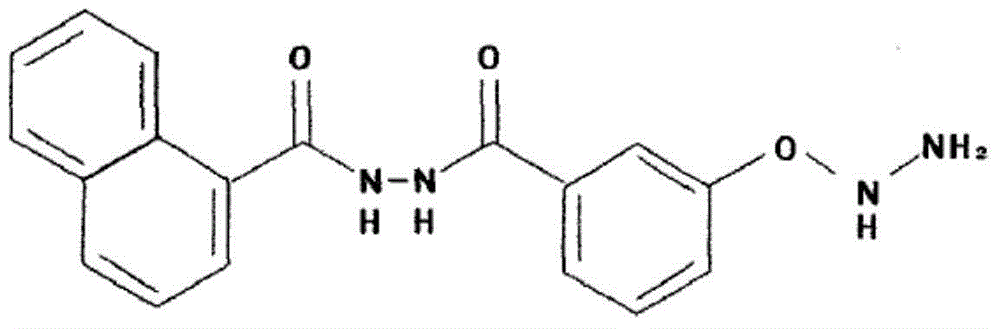

[0040] The fineness of the crystallization nucleating agent is 800 mesh, and the molecular formula is as follows:

[0041]

[0042] 2,2',6,6'-Tetraisopropyldiphenylcarbodiimide oligomer, melting point 80℃, number average molecular weight 6000, fineness 20 mesh. The oligomer is obtained by self-polymerization of 2,2',6,6'-tetraisopropyldiphenylcarbodiimide at 170-180°C.

[0043] Oxidized polyethylene wax has a melting point of 90°C, a fineness of 200 mesh, a molecular weight of 3000, and an ac...

Embodiment 5

[0058] According to the formula composition of Example 1, first mix the anti-hydrolysis stabilizer and polylactic acid evenly, then add the crystallization nucleating agent, toughening agent, and lubricant in turn for mixing, after mixing evenly, extrude through co-directional parallel twin-screws Machine blending extrusion granulation, granulation temperature is 160 ~ 180 ℃, the rest is as in Example 1.

[0059] The properties of the polylactic acid composite material in Example 5 are shown in Table 4. The properties of the polylactic acid composite material in Example 5 after being boiled for 2 hours are shown in Table 5.

[0060] Table 4 Example 5 polylactic acid composite performance table

[0061]

[0062] Table 5 Example 5 The performance table of the polylactic acid composite material after being boiled in water for 2h

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com