Rhodotorula glutinis Harrison OMK-1 and method for fermentation production of natural cinnamic acid by virtue of rhodotorula glutinis Harrison

一种天然肉桂酸、生产方法的技术,应用在一株酵母菌及利用其发酵生产天然肉桂酸领域,能够解决污染环境、分离纯化难、不利工业化等问题,达到污染少、操作简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: the production of natural cinnamic acid (erlenmeyer flask shaking fermentation)

[0043]Prepare seed culture medium, its culture medium composition is as follows (g / L): Glucose 30, potassium dihydrogen phosphate 5, urea 4, magnesium sulfate 0.8, sodium chloride 2.5, corn steep liquor 5, urea 6, solvent is water, initial pH7 .0. Sterilize at 121°C for 30 minutes.

[0044] Preparation of fermentation medium, the composition of the medium is as follows (g / L): glucose 30, potassium dihydrogen phosphate 5, urea 5, magnesium sulfate 0.6, yeast extract powder 8, ammonium sulfate 3, phenylalanine 30, solvent is water , initial pH7. Sterilize at 121°C for 30min.

[0045] Seed preparation: Aseptically transfer the Rhodotorulasp.OMK-1 strain in a low-temperature glycerol tube to a fresh, sterile solid plate, activate it at 28°C for 2 days, pick the colony and inoculate it in a 500ml triangular flask for seed cultivation, the volume of the seed medium in the bottle ...

Embodiment 2

[0047] Embodiment 2: the production of natural cinnamic acid (stirred reactor fermentation)

[0048] The preparation of seed culture medium and fermentation medium is the same as in Example 1.

[0049] Seed preparation: Aseptically transfer the Rhodotorulasp.OMK-1 strain in a low-temperature glycerol tube to a fresh, sterile solid plate, activate at 28°C for 2 days, pick colonies and inoculate them in a 3L seed tank containing 1.8L seed medium for seed culture , ventilated and stirred at a rotational speed of 300 rpm, cultivated at 30° C. for 24 hours, and obtained seed liquid.

[0050] Fermentation of natural cinnamic acid: Put 10.2L of the prepared fermentation medium into a 20L fermenter, sterilize at 121°C for 30min, then put 1.8L of the cultured seed liquid into a 20L fermenter for fermentation, the fermentation temperature is 30°C , stirring speed 400rpm, ventilation ratio 1; 0.2. Fermentation cycle 110h. Fermentation finishes measuring the concentration of natural ci...

Embodiment 3

[0051] Embodiment 3: the extraction of natural cinnamic acid

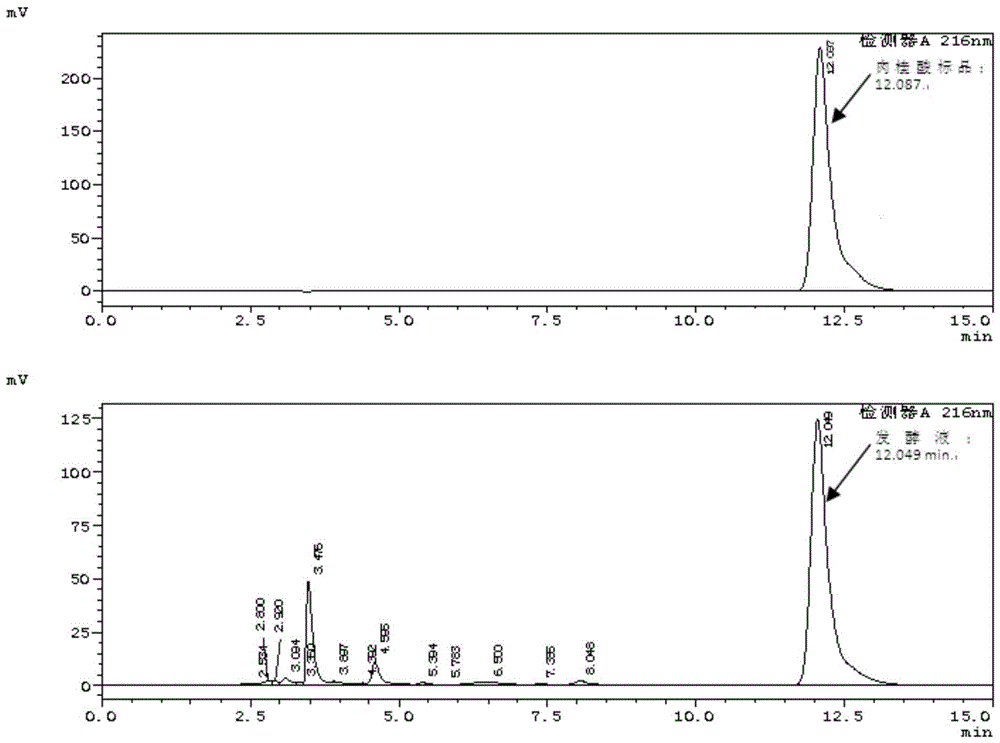

[0052] Get 50ml of fermented liquid in Example 1, heat up the water bath to 80°C, keep it warm for 30min, and inactivate the bacteria. Centrifuge the fermentation broth at 5000rpm to remove bacteria, then use dilute acid to adjust the pH to 3-5, stand still for 5 minutes, add 50ml of ethyl acetate to extract, separate layers, and use a rotary evaporator to suspend the ethyl acetate to dry the organic phase to obtain natural cinnamic acid products 0.7g. Its HPLC chart sees figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com