Flue gas desulfurization wastewater and sludge integration pretreating system and technology

A wastewater treatment system and desulfurization wastewater technology, applied in water/sludge/sewage treatment, gaseous effluent wastewater treatment, water/sewage multi-stage treatment, etc. Scale, suspended solids increase and other problems, to achieve significant economic benefits, reduce dosage, reduce investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

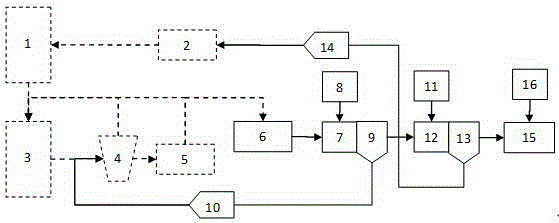

[0032] The invention also discloses an integrated pretreatment process of flue gas desulfurization wastewater and sludge. The pretreatment process is specifically as follows:

[0033] (1) The flue gas produced by the boiler is absorbed into the absorption tower 1, and lime is added to the desulfurization slurry tank 2 at the same time, mixed evenly and sprayed from the top of the absorption tower 1 to make it absorb sulfur dioxide in the flue gas and absorb sulfur dioxide slurry The reaction generates calcium sulfite and enters in the oxidation tower 3;

[0034] (2) At this time, air is blown into the oxidation tower 3 to force the calcium sulfite to oxidize and crystallize, and the oxidized slurry enters the cyclone 4 for solid-liquid separation, and the supernatant after solid-liquid separation is returned to the oxidation tower In 3, the concentrated slurry at the bottom is dehydrated by the vacuum belt dehydrator 5, and after the dehydration is completed, solid gypsum is f...

Embodiment 2

[0040] The difference between this example and Example 1 is: in step (4), the pH of sodium hydroxide and sodium carbonate is controlled to be 10.5-11.5, the dosage of sodium carbonate is 2000-5000 mg / L, the dosage of anionic polyacrylamide is The dosage is controlled to be 5-50 mg / L.

[0041] When the pretreatment process is adopted, the average fouling thickness of the inner wall of the softening device is 1.84mm after the system works continuously for 3 months.

Embodiment 3

[0043] The differences between this example and Example 1 are: in step (4), the pH of sodium hydroxide and sodium carbonate is controlled to be 11.5-13, the dosage of sodium carbonate is 5000-8000 mg / L, and the dosage of anionic polyacrylamide is 5000-8000 mg / L. The dosage is controlled to be 50-70 mg / L.

[0044] When the pretreatment process is adopted, the average fouling thickness of the inner wall of the softening device is 3.12 mm after the system has been working continuously for 3 months.

[0045] Therefore, according to the above example, the average fouling thickness of the inner wall of the softening device in Example 2 is the smallest, so the pH of sodium hydroxide and sodium carbonate is selected to be 10.5-11.5, the dosage of sodium carbonate is 2000-5000 mg / L, anionic polypropylene The dosage of amide is controlled at 5-50 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com