One-step preparation method for high nitrogen doped graphene

A graphene and high nitrogen technology, which is applied in the field of one-step preparation of high nitrogen doped graphene, can solve the problems of difficulty in realizing industrial mass production, complicated preparation process, low nitrogen doping amount, etc., and achieves low price and low preparation technology. Simple, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 6 g of urea and 0.3 g of sucrose in 20 mL of deionized water, stir to obtain an aqueous solution, and dry the above solution to obtain a white powder;

[0029] (2) The white powder is placed in a tube furnace, heated to 300° C. in a nitrogen atmosphere at a heating rate of 4° C. / min, kept for 1 hour, and the gas flow rate is 40 sccm;

[0030] (3) Continue to increase the calcination temperature to 900° C. at a heating rate of 8° C. / min and keep it warm for 2 hours, and keep the nitrogen flow rate at 40 sccm;

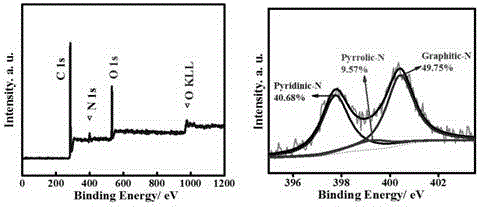

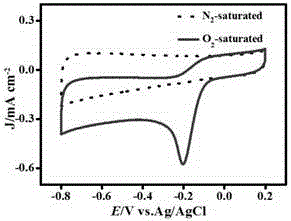

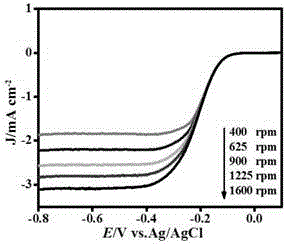

[0031] (4) After calcination, the black product was cooled to room temperature under the protection of nitrogen, and high nitrogen-doped graphene was obtained after grinding. figure 1 The scanning electron microscope image of high nitrogen-doped graphene prepared for this example shows an obvious curly layered structure accompanied by a large number of undulating wrinkles. figure 2 The transmission electron microscope image of high nitrogen-doped gr...

Embodiment 2

[0038] (1) Dissolve 6g of dicyandiamide and 0.3g of fructose in 20mL of deionized water, stir to obtain an aqueous solution, and dry the above solution to obtain a white powder;

[0039] (2) The white powder is placed in a tube furnace, heated to 300° C. in a nitrogen atmosphere at a heating rate of 4° C. / min, kept for 1 hour, and the gas flow rate is 40 sccm;

[0040] (3) Continue to increase the calcination temperature to 900° C. at a heating rate of 8° C. / min and keep it warm for 2 hours, and keep the nitrogen flow rate at 40 sccm;

[0041] (4) After calcination, the black product was cooled to room temperature under the protection of nitrogen, and high nitrogen-doped graphene was obtained after grinding. In the scanning electron microscope image of the high nitrogen-doped graphene prepared in this example, an obvious curly layered structure can be observed, accompanied by a large number of undulating wrinkles. The high-nitrogen-doped graphene prepared in this example show...

Embodiment 3

[0048] 1) Dissolve 6g of dicyandiamide and 0.3g of fructose in 20mL of deionized water, stir evenly to obtain an aqueous solution, and dry the above solution to obtain a white powder;

[0049] (2) The white powder is placed in a tube furnace, heated to 300° C. in a nitrogen atmosphere at a heating rate of 4° C. / min, kept for 1 hour, and the gas flow rate is 40 sccm;

[0050] (3) Continue to increase the calcination temperature to 1000° C. at a heating rate of 8° C. / min and keep it warm for 2 hours, and the nitrogen flow rate remains at 40 sccm;

[0051] (4) After calcination, the black product was cooled to room temperature under the protection of nitrogen, and high nitrogen-doped graphene was obtained after grinding. In the scanning electron microscope image of the high nitrogen-doped graphene prepared in this example, an obvious curly layered structure can be observed, accompanied by a large number of undulating wrinkles. The high-nitrogen-doped graphene prepared in this ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com