Compound type dust inhibiting and sand solidifying agent and preparation method thereof

A compound sand-fixing agent technology, applied in the field of dust suppressants, can solve the problems of pollution threat, difficult preparation, complicated processing technology, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

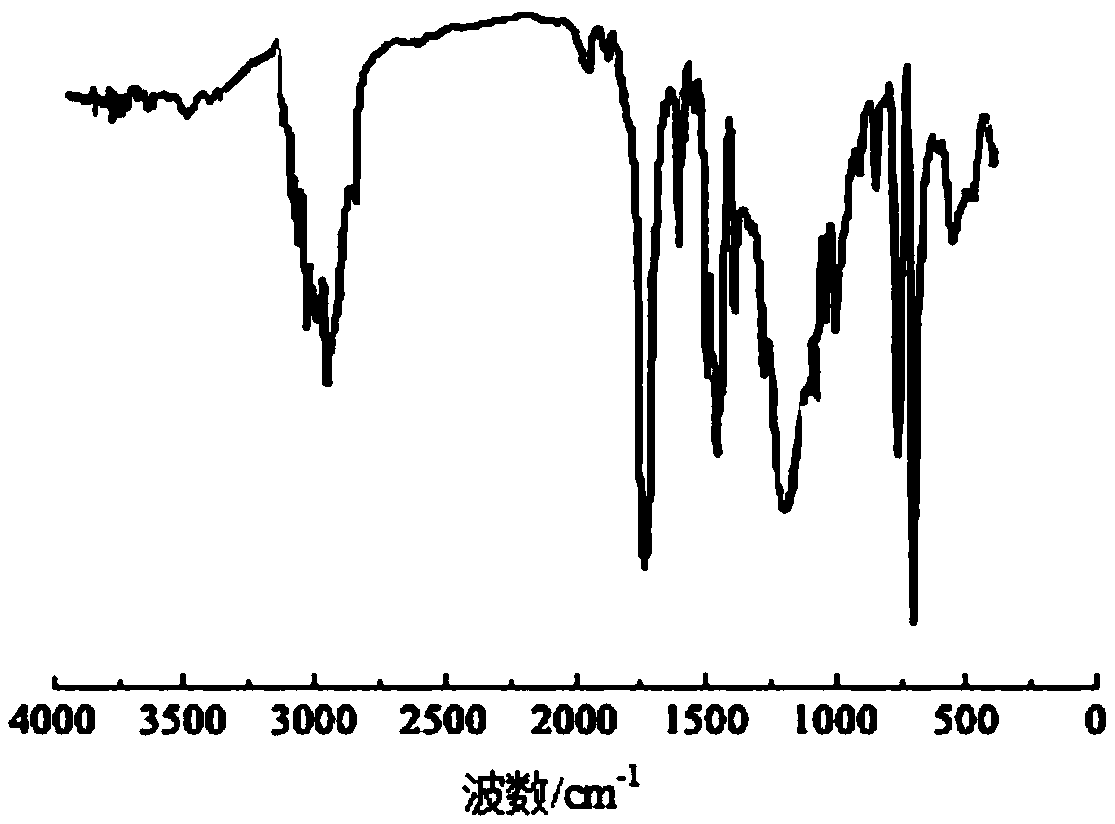

Image

Examples

Embodiment 1

[0024] (1) Take 20g of styrene, 20g of butyl acrylate, and 2g of acrylic acid in the same container, stir to mix evenly, and obtain monomer mixture A;

[0025] (2) Dissolve 0.3g of ammonium persulfate and 0.2g of sodium styrene sulfonate with 10g of deionized water to obtain a mixed solution B of initiator and reactive emulsifier;

[0026] (3) Add 100 g of deionized water to a reaction vessel equipped with a stirring device and a reflux condensing device, and stir to raise the temperature to 80°C; after the temperature stabilizes, add 25% of the monomer mixture A and 25% obtained in step (1). % of the mixed solution B obtained in step (2); seed emulsion polymerization for 20-30 minutes, start to drop the remaining monomer mixed solution A and mixed solution B, and drop it within 1-5 hours; heat up to 85-90°C and keep warm Stop the reaction for 1 hour; when the system is cooled to room temperature, adjust the pH value to 7-8 with ammonia water to obtain an acrylate emulsion;

...

Embodiment 2

[0030] (1) Take 15g of methyl methacrylate, 15g of ethyl acrylate, 5g of butyl acrylate, 2g of acrylic acid and 0.5g of acrylamide in the same container, stir to mix evenly, and obtain monomer mixture A;

[0031] (2) Dissolve 0.3g of initiator ammonium persulfate, 0.2g of sodium styrene sulfonate, 0.3g of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate with 10g deionized water to obtain initiator and reactive Mixed solution B of emulsifier;

[0032] (3) Add 100 g of deionized water to a reaction vessel equipped with a stirring device and a reflux condensing device, stir and heat up to 80° C.; after the temperature stabilizes, add 5% of the monomer mixture A and 5 obtained in step (1). % of the mixed solution B obtained in step (2); seed emulsion polymerization for 20-30 minutes, start to drop the remaining monomer mixed solution A and mixed solution B, and drop it within 1-5 hours; heat up to 85-90°C and keep warm Stop the reaction for 1 hour; when the system is c...

Embodiment 3

[0036] The composite dust suppression and sand fixation agent prepared in Examples 1 and 2 was compared with the commercially available dust suppression agent at room temperature, and the results are shown in Table 1. The main components of commercially available dust suppressant 1 are sodium silicate, phosphoric acid, and calcium chloride; the main components of commercially available dust suppressant 2 are sodium lignosulfonate and sodium silicate.

[0037] Evaluation of dilution stability: Dilute the composite dust suppressant and sand fixation agent prepared in Examples 1 and 2 and the commercially available dust suppressant 1 and 2 with water at a ratio of 1:100, respectively.

[0038] Evaluation of chemical stability: In a test tube, add 5mL of dust suppressant liquid, then add 5% CaCl 2 Solution 1mL, mix well, place at room temperature for 48h, observe whether there is precipitation, flocculation, stratification and other phenomena.

[0039] Evaluation of moisture rete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com