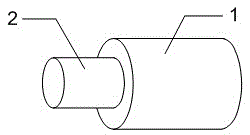

Core-shell type nano fiber bracket and method for constructing tissue engineering material by core-shell type nano fiber bracket and melanocytes

A nanofiber, core-shell type technology, applied in the field of biomedicine, to achieve good mechanical properties, good shape, and maintain the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1. Preparation of chitosan-polyethylene oxide core-shell nanofiber scaffold material

[0049] A. chitosan is dissolved with trifluoroacetic acid / dichloromethane weight ratio 3:1 mixed solvent, is made into the shell solution that concentration is 5%;

[0050] B. Dissolve polyethylene oxide, polyethylene glycol methacrylate, and polyethylene glycol dimethacrylate in water at a weight ratio of 80:20:1 to form a 5% nuclear layer solution , add 1% photoinitiator 1-[4-(2-hydroxyethoxy) phenyl]-2-hydroxyl-2 methyl-1-propane-1-one before spinning;

[0051] C. Electrospinning is carried out under the conditions of voltage of 15KV, core-shell propulsion rate of 0.5ml / h, receiving distance of 15cm, temperature of 30oC, and ultraviolet light irradiation;

[0052] D. Bake the core-shell nanofiber support under vacuum at 50oC for 12 hours;

[0053] E. At 20oC, the core-shell nanofiber scaffold was cross-linked with sodium sulfate for 2 hours, and after the cross-linking...

Embodiment 2

[0057] Embodiment 2. Preparation of chitosan-polyvinylpyrrolidone core-shell nanofiber scaffold material

[0058] A. Dissolve chitosan with acetic acid / water (weight ratio 1:1) mixed solvent to make a chitosan solution with a concentration of 2%;

[0059] B. Dissolve polyvinylpyrrolidone, hydroxyethyl methacrylate, and N,N'-methylenebisacrylamide in water at a weight ratio of 70:30:3 to form a 9% nuclear layer solution. Add 3% photoinitiator phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide before spinning;

[0060] C. Electrospinning is carried out at a voltage of 20KV, a shell-layer propulsion rate of 0.5ml / h, a core-layer propulsion rate of 1ml / h, a receiving distance of 18cm, a temperature of 20oC, and ultraviolet light;

[0061] D. the chitosan / polyethylene oxide-polyvinylpyrrolidone core-shell nanofiber support was baked under vacuum and 25oC for 24 hours;

[0062] E. Under 20oC, the chitosan-polyvinylpyrrolidone core-shell nanofiber scaffold was cross-linked with gen...

Embodiment 3

[0066] Example 3. Preparation of gelatin-polyvinyl alcohol core-shell nanofiber scaffold material

[0067] A. Dissolve the gelatin with trifluoroethanol / water (mass ratio 8:2) to make a gelatin solution with a concentration of 10%;

[0068] B. Dissolve polyvinyl alcohol, methacrylic acid, and ethylene glycol dimethacrylate in acetic acid / water (mass ratio 1:1) at a weight ratio of 60:40:0.4, and the concentration is 3%. The core layer solution, add 0.2% photoinitiator 2-hydroxyl-1-[4-(hydroxyl) phenyl]-2-methyl-1-propanone before spinning;

[0069] C. Electrospinning is carried out at a voltage of 25KV, a shell-layer propulsion rate of 1ml / h, a core-layer propulsion rate of 0.5ml / h, a receiving distance of 20cm, a temperature of 40oC, and ultraviolet light;

[0070] D. Bake the gelatin-polyethylene glycol nanofiber scaffold under vacuum at 25oC for 24 hours;

[0071] E. At 50oC, the gelatin-polyvinyl alcohol core-shell nanofiber scaffold was cross-linked with glutaraldehyde ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com