Construction method of drug sustained release system on medical titanium alloy implant surface

A construction method and implant technology, which is applied in the field of construction of drug sustained-release system on the surface of medical titanium alloy implants, can solve the problems of decreased immunity at the tissue interface, secondary trauma of patients, and susceptibility to infection, etc. Effects of shedding, increased drug loading, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

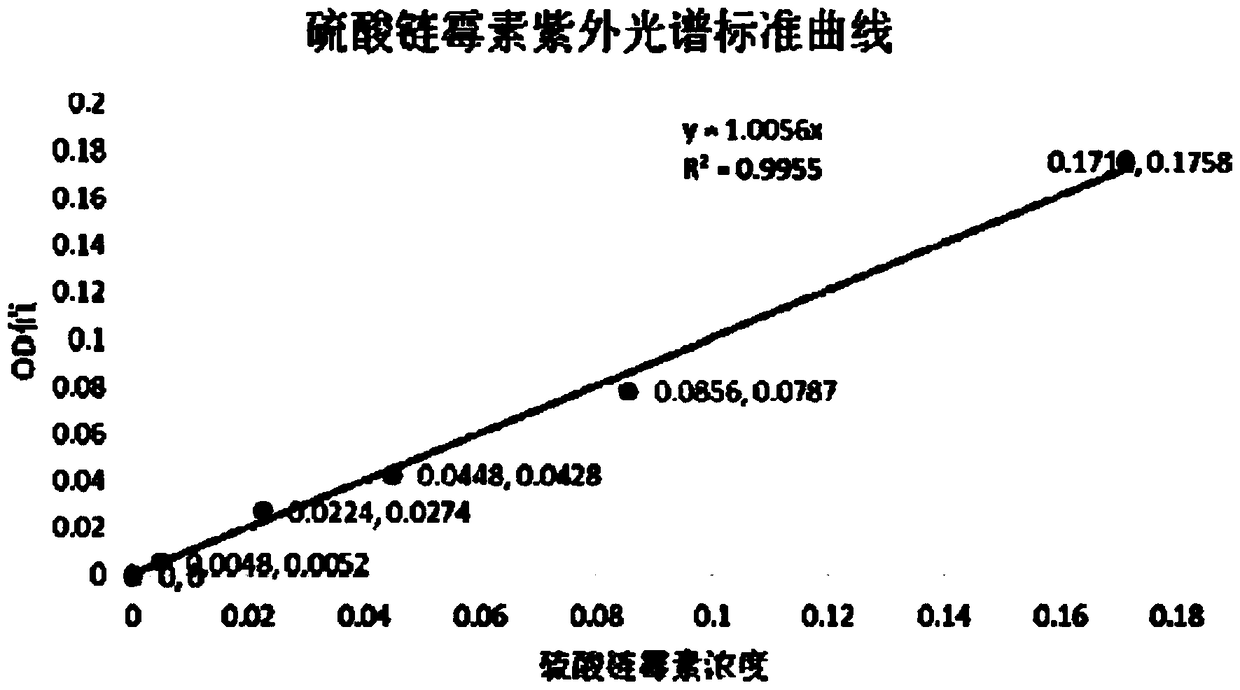

[0035] Construction of nanospheres with anti-inflammatory effects

[0036] In the case of mycobacterial infection on the surface of the implant material, streptomycin sulfate was selected as an antibacterial substance and assembled on the surface of the titanium alloy. Streptomycin sulfate has a strong antibacterial effect on Mycobacterium tuberculosis. In this experiment, MPLA microspheres containing streptomycin sulfate were prepared by self-assembly into spheres, and the coverage rate of MPLA microspheres for streptomycin sulfate was determined by ultraviolet absorption spectroscopy.

[0037] 1. Experimental materials

[0038] D, L-polylactic acid, maleic anhydride (MA analytical pure Chongqing Chuandong Chemical Co., Ltd.), dibenzoyl peroxide (BPO analytical pure Chongqing Chuandong Chemical Co., Ltd.), deionized water, dichloromethane (analytical pure Chengdu Kelong Chemical Reagent Factory), chloroform (analytical pure Chengdu Kelong Chemical Reagent Factory), ether (a...

specific Embodiment 2

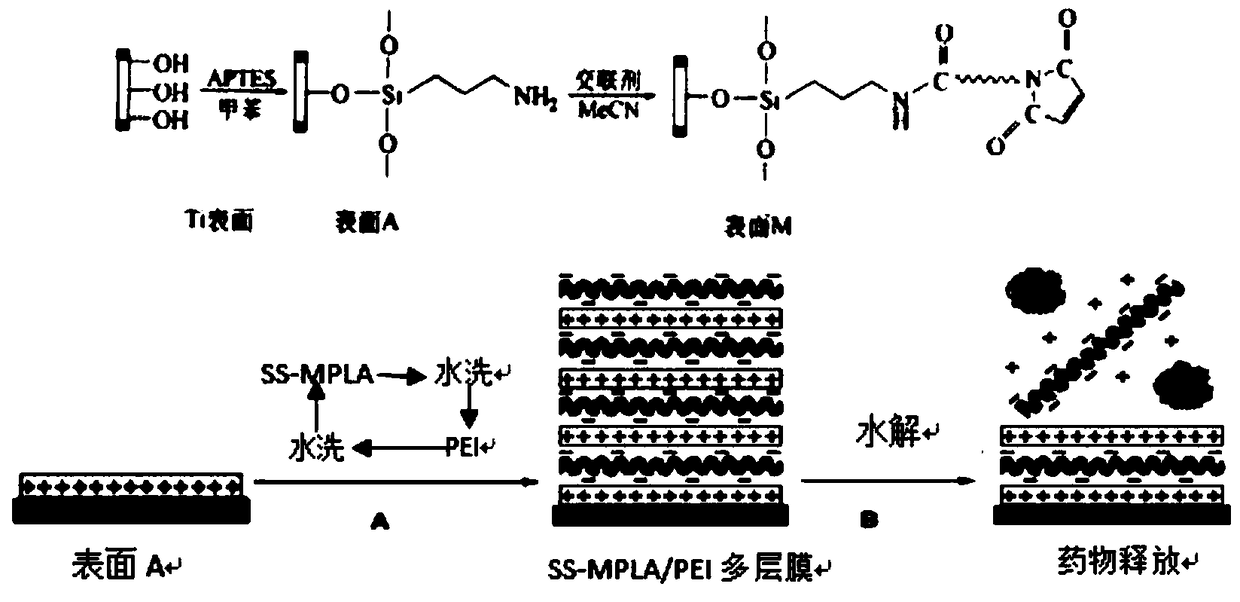

[0053] Construction of SS-MPLA / PEI Multilayer Film on Titanium Surface

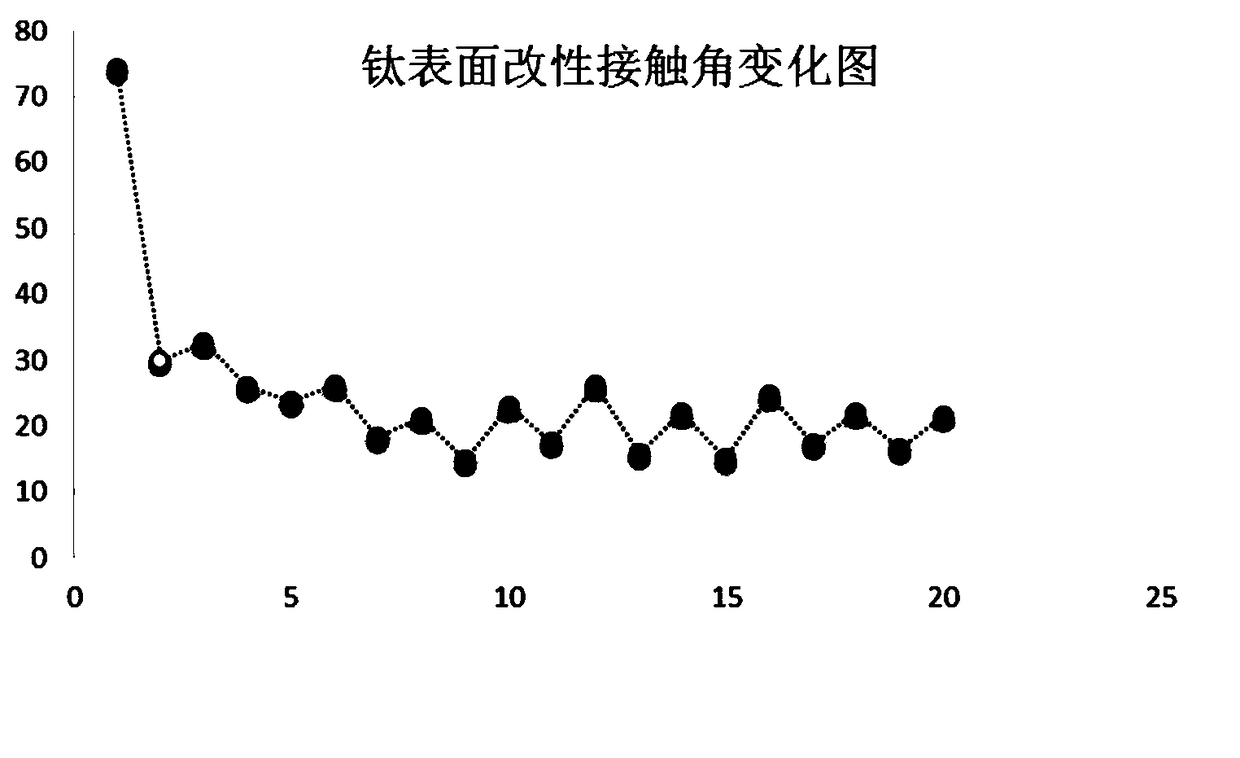

[0054] To sum up, in this experiment, titanium alloy was used as the base material, and the surface of the titanium alloy was aminated through surface graft modification. The surface of the material has more positively charged groups, which is more conducive to the later layer-by-layer self-assembly steps. Through layer-by-layer self-assembly technology, a multi-layer film was constructed on the surface of titanium amide, and a sustained-release system for antibacterial drug streptomycin sulfate was established. MPLA microspheres and PEI were used as polyanions and cations, respectively, and electrostatic adsorption was used to achieve SS-MPLA microspheres. Ball / PEI multilayer film, the formation of multilayer film can be judged indirectly by contact angle. figure 2 It is a schematic diagram of titanium surface amination and further layer-by-layer self-assembly process.

[0055] 1. Experimental materia...

specific Embodiment 3

[0075] Verification of sustained release effect of antibacterial film on titanium alloy surface

[0076] 1. Experimental materials

[0077] The surface NH 2 / (SS-MPLA / PEI) 5 ; NH 2 / (SS-MPLA / PEI) 10 Multilayer film; phosphate buffered saline (PBS, 0.1M, pH=7.4): ferric ammonium sulfate ((NH 4 ) 2 SO 4 · Fe 2 (SO 4 ) 3 24 hours 2 O analytically pure Chongqing Chuandong Chemical Co., Ltd.); sodium hydroxide (analytical pure Chongqing Chuandong Chemical Co., Ltd.); concentrated sulfuric acid (analytical pure Chongqing Chuandong Chemical Co., Ltd.); deionized water.

[0078] 2. Experimental method

[0079] 5 NH prepared by the method of the above-mentioned specific example two 2 / (SS-MPLA / PEI) 5 Titanium sheet, 5 NH 2 / (SS-MPLA / PEI) 5 Put the titanium sheets into the cell culture dishes respectively, add 3ml of 0.1M phosphate buffer (pH=7.4) to the 10 cell culture dishes, cover and seal, and place at room temperature; at 1, 3, 6, 12, During the period of 24, 36, 48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com