Ultra-long carbon nanotube preparation device and preparation method

A technology for ultra-long carbon nanotubes and preparation devices, which is applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., which can solve the problem of smooth passage of unfavorable airflow, inability to obtain mass production capacity, and reduction of substrate utilization. and other problems to achieve the effect of improving safety, high crystallinity and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

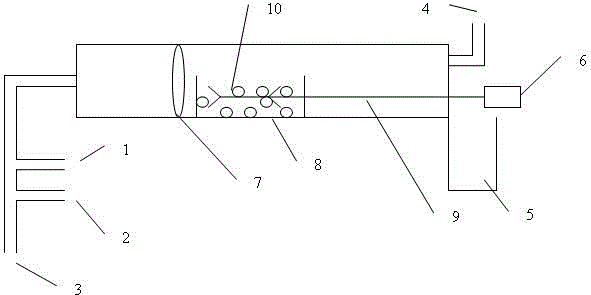

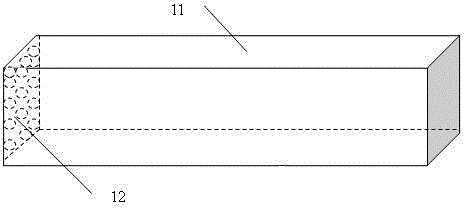

[0037] like figure 1 Shown, be the used structure of main implementation method of the present invention, comprise the steps:

[0038] Put the quartz glass microspheres into the quartz boat and push them into the reaction zone of the quartz tube, use benzene as the carbon source, dissolve 1% ferrocene as the catalyst, the growth temperature is 720°C, the carrier gas is nitrogen, and the carrier gas flow rate is 20ml / min, the growth time is 0.5 hours. The injection rate of the mixture of benzene and ferrocene is 0.1ml / h. After the growth is over, stop injecting the mixed solution, start injecting water, and inject 1 volume of 0.5 ml, stop the water supply after the temperature drops to 400 degrees, open the outlet flange to scrape off the carbon nanotubes on the tube wall at one time and collect them in the tube. in the collection container placed under the tail.

Embodiment 2

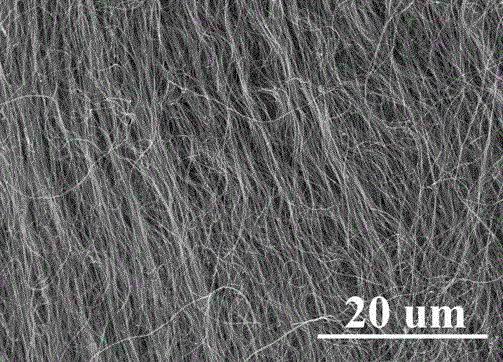

[0040]Put the quartz glass microspheres into the quartz boat and push them into the reaction zone of the quartz tube, use acetone as the carbon source, and dissolve 4% ferric chloride as the catalyst, the growth temperature is 600°C, the carrier gas is argon, and the carrier gas flow rate is 800ml / min, the growth time is 2 hours. When the injection rate of the mixture of acetone and ferric chloride is 10ml / h. Stop injecting the toluene ferrocene solution after the growth is over, start water injection, the injection volume is 100ml, stop the water flow when the temperature drops to 400 degrees, open the inlet flange to take out the carbon nanotubes, the microscopic appearance of the carbon nanotubes is as follows image 3 shown.

Embodiment 3

[0042] Put the quartz glass microspheres into the quartz boat and push them into the reaction zone of the quartz tube, using n-hexane as the carbon source, dissolving 2% ferric nitrate as the catalyst, the growth temperature is 1000°C, and the carrier gas is a mixture of argon and nitrogen. The carrier gas flow rate was 1600ml / min, and the growth time was 8 hours. The injection rate of n-hexane and ferric nitrate mixture is 25ml / h. Stop injecting the mixed solution after the growth is over, start injecting water, the injection volume is 300ml, stop the water flow when the temperature drops to 400 degrees, and take out the carbon nanotubes after the temperature drops to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com