A method for enzymatically preparing d-tagatose

An enzymatic preparation and tagatose technology, which is applied in the directions of botanical equipment and methods, biochemical equipment and methods, enzymes, etc., can solve the problems of increasing downstream separation supporting links, increasing production costs, and limiting conversion rate, and achieves simplification. The effect of post-separation and other operational processes, reduction of downstream operations, and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

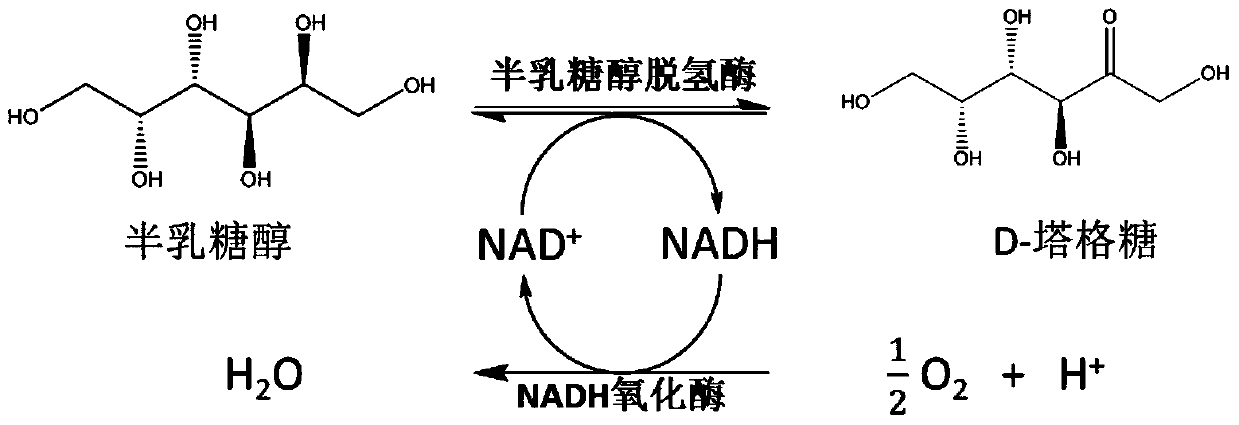

Method used

Image

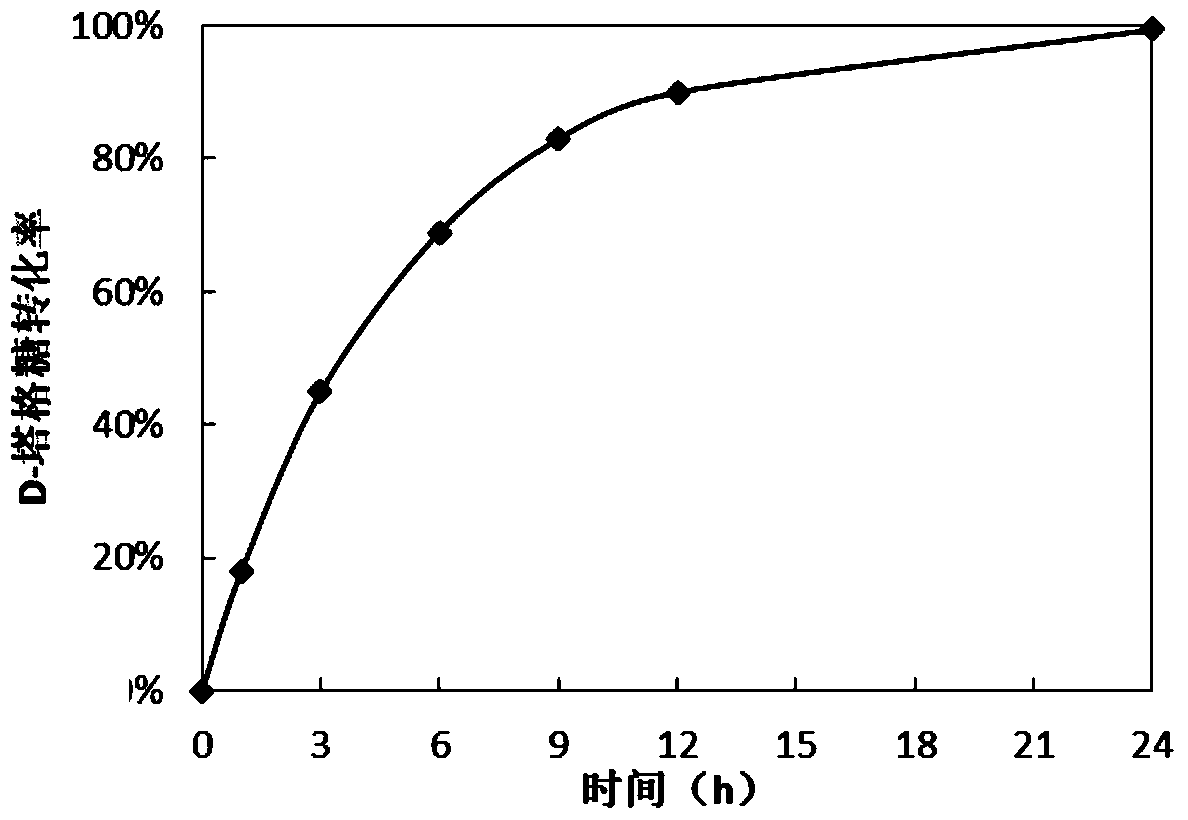

Examples

Embodiment 1

[0027] Embodiment 1: Source and acquisition of galactitol dehydrogenase gene

[0028] This example provides a polynucleotide molecule encoding a polypeptide having galactitol dehydrogenase activity. The nucleotide molecule is artificially synthesized by Suzhou Jinweizhi Biotechnology Co., Ltd. and has a nucleoside of SEQ ID NO: 1 acid sequence, which encodes the 239 amino acid polypeptide of SEQ ID NO:2.

Embodiment 2

[0029] Embodiment 2: Construction of recombinant expression vector pET-28a-gdh

[0030] Use NcoI and BamHI to digest pET-28a (purchased from Novagen Merck China) and the target gene containing two restriction sites (artificially synthesized in Example 1), respectively, and recover the double-digested target fragment and Expression vector, the double-digested expression vector pET-28a and the target gene (the gene shown in SEQ ID NO: 1) were connected overnight with T4-DNA ligase (purchased from TaKaRa Company) to obtain the recombinant vector pET-28a -gdh; add 10 μL of the ligation product to 100 μL of Escherichia coli BL21 competent cells, place on ice for 30 min, and heat shock at 42°C for 90 s. Place on ice for 2 minutes. Add pre-warmed 0.45 mL SOC medium (2% (W / V) peptone, 0.5% (W / V) yeast extract, 0.05% (W / V) NaCl, 2.5 mM KCl, 10 mM MgCl2, 20 mM glucose). 220rpm, 37°C, 1h. Add 200 μL of the bacterial solution to an LB plate containing 30 μg / mL kanamycin, and culture ov...

Embodiment 3

[0031] Example 3: Cloning of NADH oxidase gene

[0032] Streptococcus thermophiles were purchased from China General Microorganism Culture Collection Center (CGMCC). MRS medium for Streptococcus thermophilus culture (g L-1): beef extract 10.0, yeast extract 5.0, casein peptone 10.0, glucose 5.0, sodium acetate 5.0, diamine citrate 2.0, Tween 80 1.0, phosphoric acid Dipotassium hydrogen dipotassium 2.0, magnesium sulfate 0.2, manganese sulfate 0.05, calcium carbonate 20.0, completely dissolved in 950mL deionized water, adjust pH to 6.8 with 5mmol·L-1 NaOH, constant volume 1L, 110℃, autoclaved for 15min .

[0033] Streptococcus thermophilus was inoculated in 5 mL of MRS liquid medium, cultured at 42°C until logarithmic growth phase, and the genome of Streptococcus thermophilus was extracted using DNAKit (TIANGEN, China). The primers used to construct the expression vectors are provided with enzyme cutting sites, and the primer sequences are as follows:

[0034] The upstream p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com