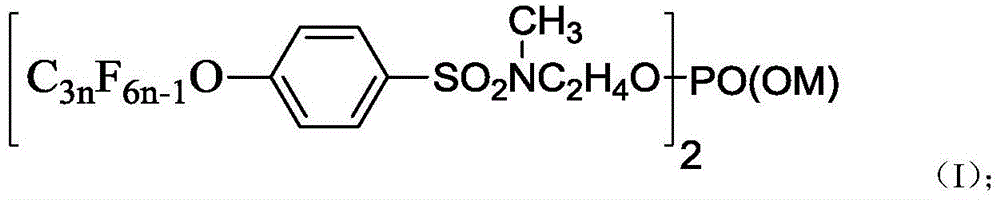

Fluorine-containing phosphate surfactant and preparation method thereof

A surfactant, fluorine-containing phosphoric acid ester technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of low bioaccumulation, difficult to obtain raw materials, and many reaction steps, and achieve the reaction yield. High, cheap raw materials, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

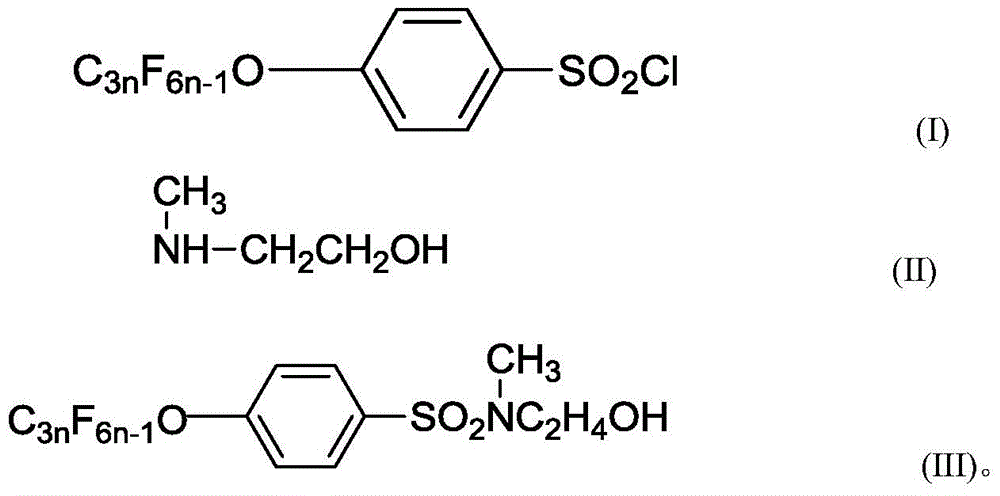

Method used

Image

Examples

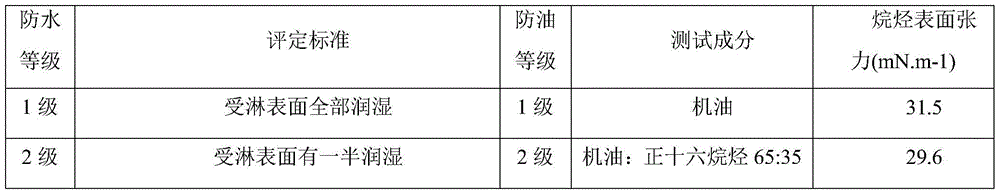

Embodiment 1

[0031] Add 30mL of acetonitrile, 6.22g (0.01mol) of 4-perfluorononenyloxybenzenesulfonyl chloride, 0.75g (0.01mol) of 2-methylaminoethanol, 1.06g (0.01mol) of anhydrous carbonic acid in a 100mL four-necked flask Sodium, stir, heat up to 0°C, keep the temperature and stir for 2h, distill the reaction solution under reduced pressure until no solvent comes out, cool to room temperature, wash the viscous oil obtained with water, and recrystallize with acetonitrile to obtain white crystal N-hydroxyethyl -N-methyl-4-perfluoroalkenyloxybenzenesulfonamide, yield 85%, the gained N-hydroxyethyl-N-methyl-4-perfluoroalkenyloxybenzenesulfonamide is equipped with a stirrer , a condenser tube, and a 250mL four-necked flask with a thermometer, start the stirrer and raise the temperature to 30°C, add 3.55g of phosphorus pentoxide in batches, the temperature will gradually increase, and the reaction will start, and the reaction temperature will be maintained at 30°C. After 24 hours, the tempera...

Embodiment 2

[0033]Add 30mL of dichloromethane, 6.22g (0.01mol) of 4-perfluorononenyloxybenzenesulfonyl chloride, 3.75g (0.05mol) of 2-methylaminoethanol, 4.04g (0.04mol) of trichloromethane into a 100mL four-necked flask Ethylamine, stirred, heated up to 80°C, kept at the temperature and stirred for 12 hours, the reaction solution was distilled under reduced pressure until no solvent came out, cooled to room temperature, washed with water, and recrystallized with acetonitrile to obtain white crystal N-glycolic acid Base-N-methyl-4-perfluoroalkenyloxybenzenesulfonamide, yield 98.7%, gained N-hydroxyethyl-N-methyl-4-perfluoroalkenyloxybenzenesulfonamide is equipped with stirring In a 250mL four-neck flask with a condenser, a condenser, and a thermometer, start the stirrer and raise the temperature to 80°C, add 3.55g of phosphorus pentoxide in batches, the temperature will gradually rise, and the reaction will start. Keep the reaction temperature at 90-110°C. ℃, the reaction time is 6h, the ...

Embodiment 3

[0035] In a 100mL four-necked flask, add 30mL N,N-dimethylformamide, 6.22g (0.01mol) 4-perfluorononenyloxybenzenesulfonyl chloride, 1.5g (0.02mol) 2-methylaminoethanol, 6.9 g (0.05mol) of anhydrous potassium carbonate, stirred, heated up to 150°C, kept at the temperature and stirred for 6 hours, distilled the reaction solution under reduced pressure until no solvent came out, cooled to room temperature, washed the obtained viscous oil, recrystallized with acetonitrile, Obtain white crystal N-hydroxyethyl-N-methyl-4-perfluoroalkenyloxybenzenesulfonamide, yield 93%, the gained N-hydroxyethyl-N-methyl-4-perfluoroalkenyloxy Benzenesulfonamide is in a 250mL four-necked flask equipped with a stirrer, a condenser, and a thermometer, and the temperature of the stirrer is raised to 200°C, and 3.55g of phosphorus pentoxide is added in batches, and the temperature gradually increases, and the reaction starts. The reaction temperature is maintained at 180-200°C, the reaction time is 10h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com