Peptide protein feed and preparation method thereof

A peptide protein and feed technology, applied in the field of peptide protein feed and its preparation, can solve the problems of low content of small peptide protein, low content of small peptide, less degradation of anti-nutritional factors, etc., and achieves increased organic acid content and fecal excretion. The effect of reducing and increasing the content of small peptides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation method of peptide protein feed

[0024] 1. The method of preparing lactic acid bacteria liquid: (1) Lactic acid bacteria secondary seed liquid culture: ① Weigh the ingredients in the first medium, namely 30g peptone, 10g yeast extract, 300g molasses, 8g sodium acetate, 3g dipotassium hydrogen phosphate As well as Tween-806g, add 1kg of water, and then sterilize by boiling for 20 minutes. After sterilization, add water to 6kg and cool to 37 degrees (if it is winter, it can be reduced to 39 degrees); ②Inoculate Lactobacillus plantarum one 10g first-class strain of Streptococcus suis and 10g first-class strain of Streptococcus faecalis, cultivated at 37°C for 24-36 hours, stirred once for 2-3 hours, to obtain the second-level strain of lactic acid bacteria; (2) Culture of the third-level strain of lactic acid bacteria: ①Prepare the second medium: weigh 1000g peptone, 350g yeast extract, 15kg molasses, 30g sodium acetate, 300g dipotassium hydrogen phosph...

Embodiment 2

[0030] (1) Peptide protein feed: feed cake 1100kg, fermentation broth 38kg, 50000μ / g mannanase 0.12kg, 100000μ / g xylanase 0.18kg, 10000μ / g cellulase 0.12kg, 50000μ / g glucosamine Glycanase 0.08kg, molasses 35kg and water 430kg. The feed meal includes at least one of soybean meal, rapeseed meal or cottonseed meal; the fermentation bacteria liquid includes lactic acid bacteria liquid and yeast liquid, and the mass ratio of the two is 1:1. The preparation method of the peptide protein feed is the same as in Example 1.

[0031] (2) Peptide protein feed: 900kg of feed cake, 46kg of fermented bacteria liquid, 0.08kg of 50,000μ / g mannanase, 0.22kg of 100,000μ / g xylanase, 0.08kg of 10,000μ / g cellulase, and 50,000μ / g of glucose Glycanase 0.12kg, molasses 25kg and water 480kg. The feed cake includes soybean meal, rapeseed meal and cottonseed meal; the fermentation bacteria liquid includes lactic acid bacteria liquid and yeast liquid, and the mass ratio of the two is 1:1. The preparation ...

Embodiment 3

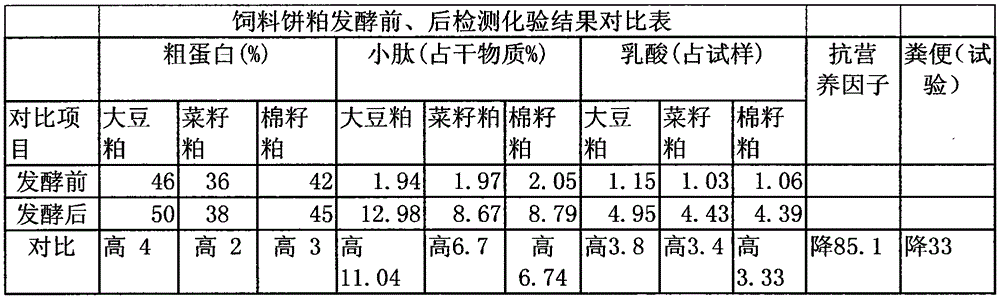

[0034] Fermentation is carried out by the method of the present invention, and the results obtained are shown in the following table:

[0035]

[0036] It can be seen from the above examples and tables:

[0037] ①The net increase of protein through fermentation, and higher biological activity, better digestion and absorption. Especially in animals (especially young animals), the total absorption of small peptides in the intestines and stomach is greatly increased, which can partially and completely replace fish meal.

[0038] ②The fermentation of lactic acid and other organic acids can greatly promote the digestion and absorption of feed in the gastrointestinal tract.

[0039] ③ Through biological detoxification, degradation and modification during fermentation, the anti-nutritional factors in the raw meal are greatly reduced and stress is reduced.

[0040] ④The rich probiotics and vitamins in fermented products can effectively improve the microecological environment of the digestive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com