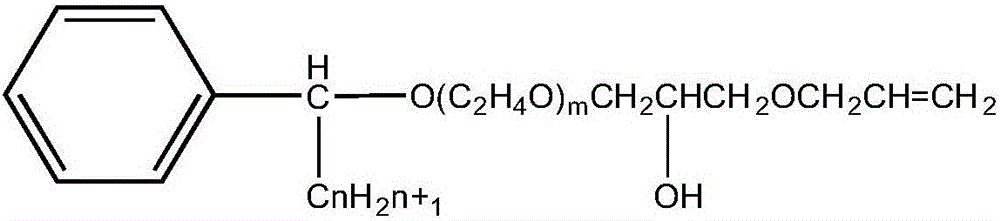

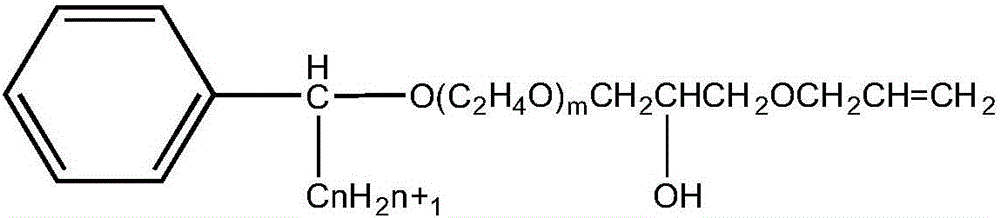

Alpha-phenyl alkyl alcohol polyoxyethylene ether hydroxypropyl allyl ether as well as derivative and preparation method thereof

A technology of polyoxyethylene ether hydroxypropyl allyl ether and phenyl alkyl alcohol, which is applied in the field of polymer additive synthesis and can solve the problems of decreased water resistance of emulsion films, decreased color development of coating films, and decreased emulsifying ability, etc. problem, to achieve the effect of stable derivative properties, excellent wetting, and less foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

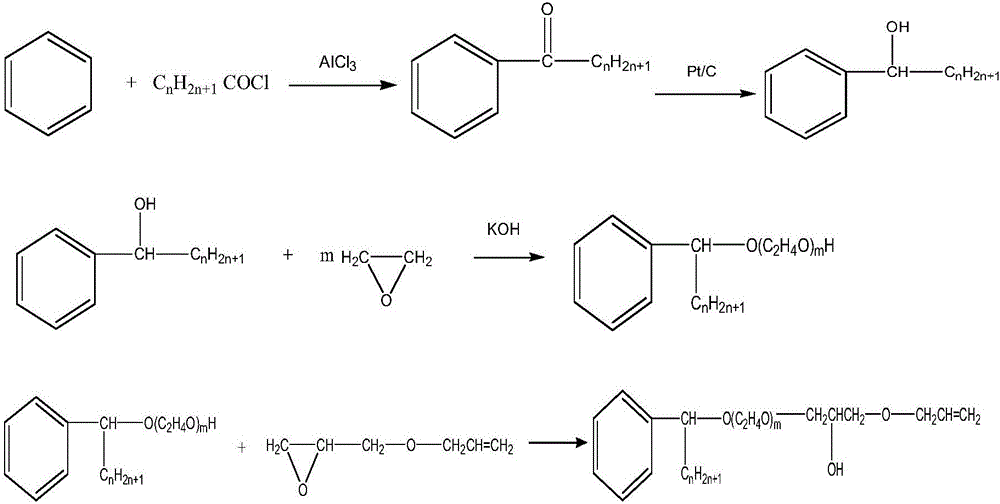

[0040] A kind of APEO-free α-phenyl octanol polyoxyethylene ether (10) hydroxypropyl allyl ether reactive emulsifier, its preparation process is as follows:

[0041] Step a. In a reaction kettle, use excess benzene as a solvent, add aluminum trichloride catalyst, add octanoyl chloride dropwise at a temperature of 40-70°C, hydrolyze and neutralize after the reaction, and distill under reduced pressure to remove benzene to obtain intermediate Body α-phenyloctanone, for use;

[0042] Step b. In a hydrogenation autoclave, under the conditions of a palladium-carbon catalyst, a temperature of 130-170° C., and a pressure of 2.0-3.0 mPa, α-phenyloctanone is hydrogenated and reduced to obtain α-phenyloctanol, stand-by;

[0043]Step c, put α-phenyloctanol and catalyst KOH into the reaction kettle, then heat up and vacuum dehydrate; after dehydration is completed, after passing through nitrogen replacement, the molar ratio of α-phenyloctanol / ethylene oxide is 1:( 10-12) Slowly feed eth...

Embodiment 2

[0047] A kind of APEO-free α-phenyloctyl alcohol polyoxyethylene ether (15) hydroxypropyl allyl ether reactive emulsifier, its preparation process is as follows:

[0048] Step a. In a reaction kettle, use excess benzene as a solvent, add aluminum trichloride catalyst, add octanoyl chloride dropwise at a temperature of 40-70°C, hydrolyze and neutralize after the reaction, and distill under reduced pressure to remove benzene to obtain intermediate Body α-phenyloctanone, for use;

[0049] Step b. In a hydrogenation autoclave, under the conditions of a palladium-carbon catalyst, a temperature of 130-170° C., and a pressure of 2.0-3.0 mPa, α-phenyloctanone is hydrogenated and reduced to obtain α-phenyloctanol, stand-by;

[0050] Step c, put α-phenyloctanol and catalyst KOH into the reaction kettle, then heat up and vacuum dehydrate; after dehydration is completed, after passing through nitrogen replacement, the molar ratio of α-phenyloctanol / ethylene oxide is 1:( 15-16) Slowly fe...

Embodiment 3

[0054] A kind of APEO-free α-phenyl isononyl alcohol polyoxyethylene ether (9) hydroxypropyl allyl ether reactive emulsifier, its preparation process is as follows:

[0055] Step a, in a reaction kettle, use excess benzene as a solvent, add aluminum trichloride catalyst, add isononanoyl chloride dropwise at a temperature of 40-70°C, hydrolyze and neutralize after the reaction, and remove benzene by distillation under reduced pressure to obtain Intermediate α-phenyl isononyl ketone, ready for use;

[0056] Step b. In a hydrogenation autoclave, under the conditions of a palladium-carbon catalyst, a temperature of 130-170° C., and a pressure of 2.0-3.0 mPa, α-phenylisononyl ketone is hydrogenated and reduced to obtain α-phenylisononyl ketone Nonyl alcohol, ready to use;

[0057] Step c, put α-phenylisononyl alcohol and catalyst KOH into the reaction kettle, then heat up and vacuum dehydrate; after dehydration is completed, after nitrogen replacement, the moles of α-phenylisonony...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com