A kind of Aspergillus niger strain and application thereof

A strain of Aspergillus niger, the technology of Aspergillus niger, applied in the field of microorganisms, can solve the problems of increasing the purification and blending process, increasing labor and cost, etc., and achieves the effects of good enzyme production effect, convenient operation and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Acquisition of strains

[0033] Separation and screening are from the soil humus layer of Taibai Mountain. The medium used for separation and screening is sodium carboxymethyl cellulose screening medium. The specific components are as follows: sodium carboxymethyl cellulose 10.0g, KH 2 PO 4 1.0g, NaCl 0.1g, MgSO 4 7H 2 O 0.3g, NaNO 3 2.5g, FeCl 3 0.001g, CaCl 2 0.1g, Congo red 0.2g, agar 18g, H 2 O 1000mL, pH natural.

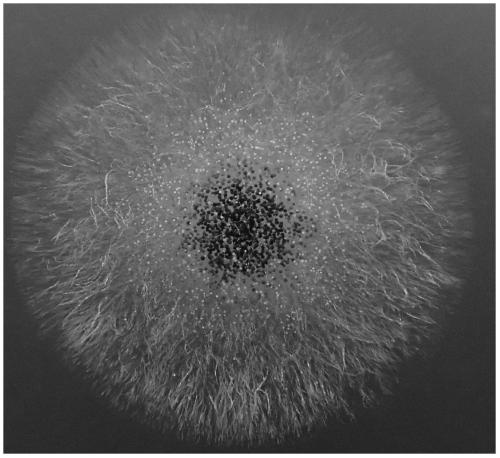

[0034] (2) Culture characteristics of the strain

[0035]The Aspergillus niger bacterial strain of the present invention is cultured on PDA agar medium, under 25 ℃ of dark conditions for 7 days, colony diameter 70mm, initial texture is nearly fluffy, and colony is circular, flat, dense, stout, orderly, after producing spores with powder granular, such as figure 1 shown. Wherein, the composition of PDA agar medium is: potato 200g, glucose 20g, agar 20g, distilled water 1000ml, pH is natural.

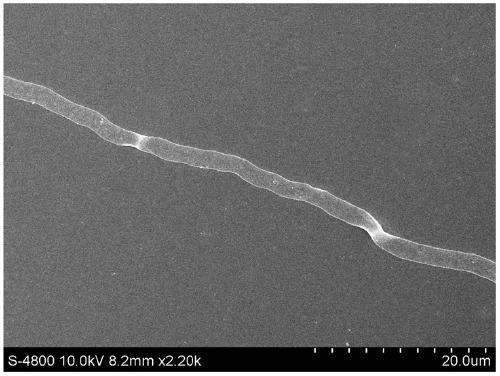

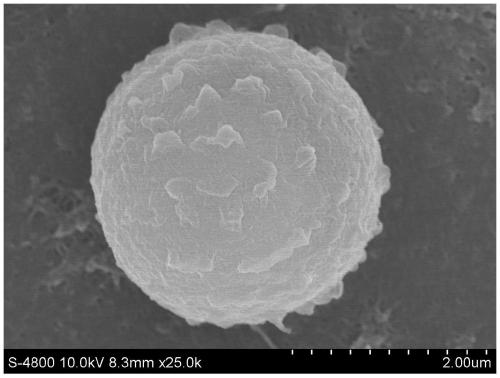

[0036] (3) Morphological characteristics o...

Embodiment 2

[0042] The Aspergillus niger (Aspergillus niger) Z-9 bacterial strain of the present invention can use crop stalks as a carbon source to produce cellulase through liquid fermentation. Put it into sterilized 80mL liquid fermentation medium, cultivate it on a shaker at 200r / min at 30°C for 5 days, and obtain a cellulase-containing fermentation broth, which is centrifuged at 8000r / min and suction-filtered to obtain crude Enzyme solution; wherein, the composition of the liquid fermentation medium is: wheat straw powder 2g, bran 20g, microcrystalline cellulose 6g, bean cake powder 5g, ammonium sulfate 2g, urea 1g, sodium nitrate 2g, potassium dihydrogen sulfate 3g, magnesium sulfate 0.5g, Tween 803mL, tap water 1000mL, pH natural.

[0043] The crude enzyme solution was determined, in which the cellulase filter paper enzyme activity (FPA) was 64.67U / mL, and it also contained xylanase and pectinase, the enzyme activities were 216.70U / mL and 66.91U / mL respectively, and the FPA enzyme ...

Embodiment 3

[0046] Preparation of Aspergillus niger (Aspergillus niger) Z-9 spore preparation: Weigh 50g of bran in a 650ml tissue culture bottle, add 60ml of tap water, sterilize at 121°C for 30min, inoculate 5ml of Aspergillus niger spore suspension after cooling, stir well, and use Four layers of sterile gauze were sealed, and cultured at a constant temperature of 28°C. After 24 hours of culture, mycelia began to grow in large quantities. After 36 hours of culture, the mycelia were covered with fermentation substrates. The results of sampling test showed that the germination rate of Aspergillus niger Z-9 spores reached 99.5%, and the Aspergillus niger spores had the characteristics of easy preparation, survival and cultivation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com