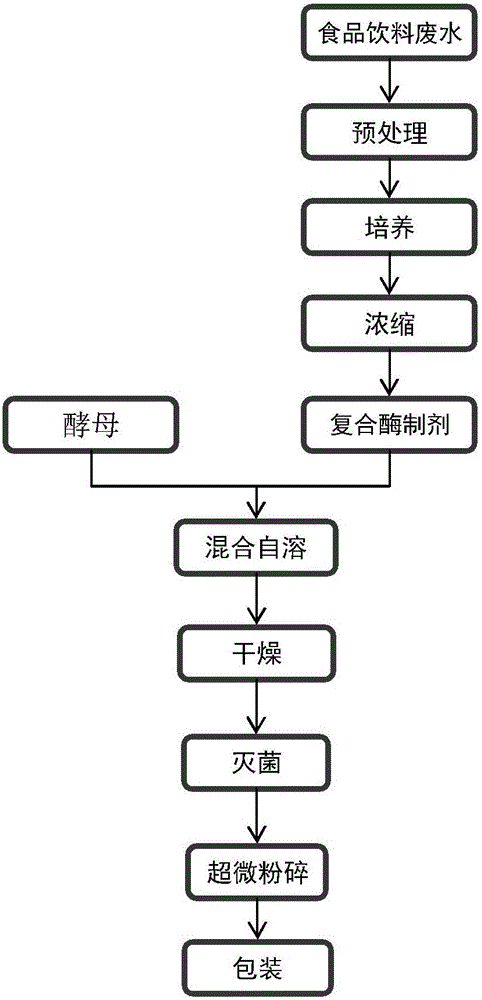

Method for preparing yeast autolysate from single-cell protein complex enzyme preparation cultured by food and beverage production wastewater and produced yeast product

A technology for compound enzyme preparation and waste water production, which is applied in the production and application of single-cell protein, can solve the problems of low yeast autolysis efficiency, etc., and achieve the effects of reducing the operation of the insulation system, high biological safety, and improving the purity of the enzyme.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

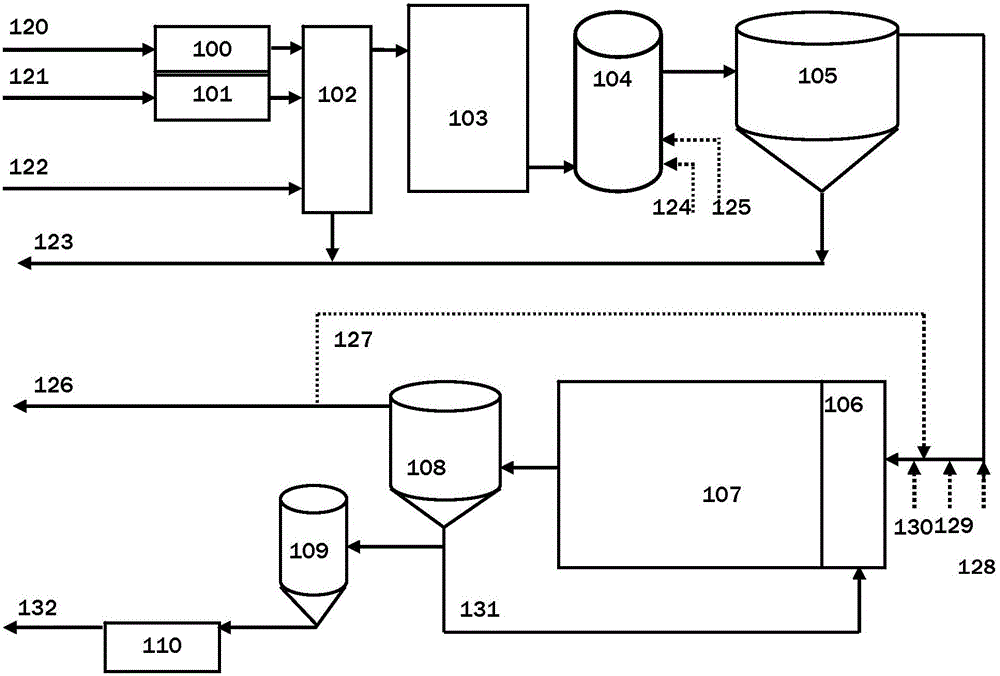

[0128] Embodiment 1: Utilize beer wastewater to produce single-cell compound enzyme preparation for enzymatic hydrolysis of protein feed

[0129] Raw materials: The main components of beer wastewater are: sugars, alcohols, amino acids, pectin, hops, vitamins, protein compounds, organic matter and a small amount of inorganic salts in the packaging workshop, etc. BOD / COD is higher, with an average of 0.55. And there are a lot of suspended matter, such as wheat dregs, etc., and there are often alkaline cleaning agents and fungicides that are put into the disinfection and cleaning process. The water quantity and quality of beer wastewater depends on the production cycle, and the water quantity and quality fluctuate greatly. The amount of wastewater in the production period is huge, the COD is 2000-4000mg / L, and the pH value is mainly slightly alkaline to medium alkaline.

[0130] Production Process:

[0131] The production process uses the existing wastewater treatment system o...

Embodiment 2

[0154] Embodiment 2. The production of molasses glutamic acid production waste water is used for the single-cell composite enzyme preparation of protein feed enzymolysis

[0155] Raw materials: The specific characteristics of the wastewater produced by molasses glutamic acid are as follows: the waste liquid is brown in appearance, with a small amount of bubbles on the surface, strong acidity, high concentration of organic matter, COD load as high as 30000-70000mg / L, BOD load as high as 20000-42000mg / L , high content of suspended solids, 12000-20000mg / L. Wastewater contains a large amount of organic acids by-products of microbial metabolism, mainly lactic acid, succinic acid, etc. The total amount of amino acids in molasses glutamic acid wastewater is as high as 7%. Except for residual glutamic acid, other residual amino acids mainly include aspartic acid, Alanine, glycine, valine, leucine, isoleucine, phenylpropoxyacid, lysine, arginine, etc., and residual sugar, urea, etc. in...

Embodiment 3

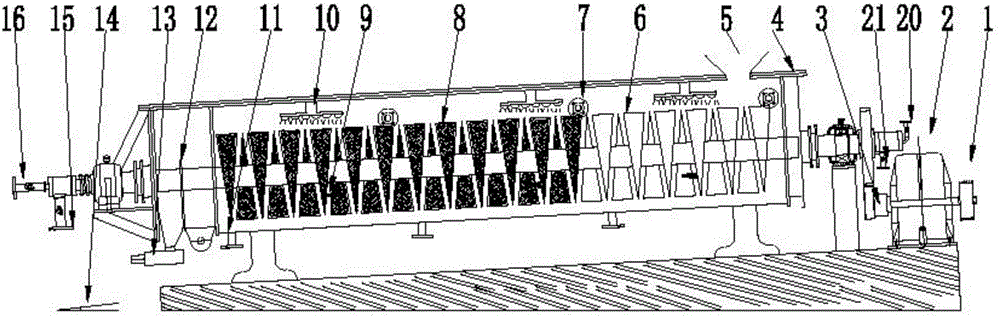

[0192] Embodiment 3: This example is the manufacturing example of raw material selection, autolysis production

[0193] In this example, the compound flora rich in endogenous enzymes cultivated in real time from the organic wastewater of the beer factory is used as the raw material of the single-cell compound enzyme preparation. The water content is 90% to 98%, and the water content is reduced to 80% to 85% after centrifugal dehydration. The protein content (dry basis) of the prepared single-cell composite enzyme preparation is higher than 50%, and it is transported to Autodissolving equipment.

[0194] The yeast is commercially available common dried non-autolyzed beer yeast with a protein content of 50%.

[0195] Add the prepared single-cell compound enzyme preparation and yeast at a ratio of 50% / 50% of dry matter, and the addition method of the ratio is realized by the frequency of the screw conveying pump and the motor of conveying Jiaolong.

[0196] In addition to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dissolved oxygen | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com