Laminated laundry detergent tablet and preparation method thereof

A technology of detergent and film coating agent, which is applied in the field of daily chemicals, can solve the problems of large influence of storage humidity, poor product stability, and product failure, and achieve the effects of reducing disintegration time, high stability, and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

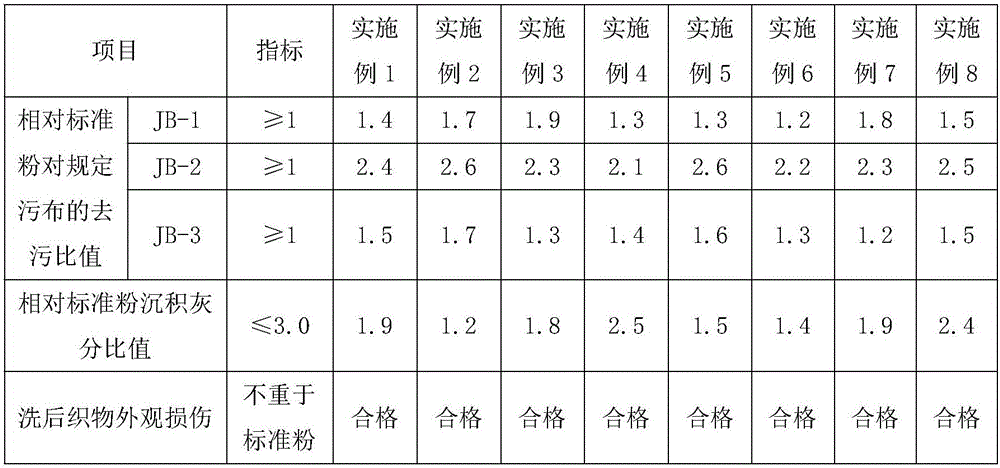

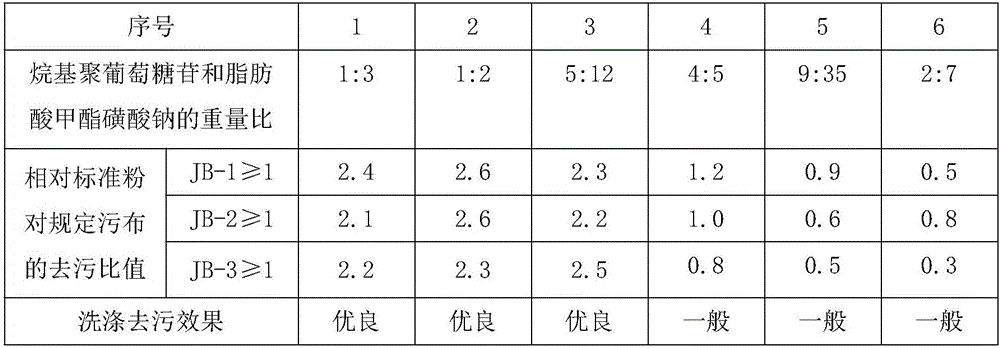

Examples

Embodiment 1

[0038] Raw material formula: fatty alcohol polyoxyethylene ether 8%, sodium dodecylsulfonate 25%, disodium edetate 5%, polyvinylpyrrolidone 0.3%, citric acid 25%, sodium carbonate 25%, cross-linked Sodium carboxymethyl cellulose 2%, polyethylene glycol 4000 1.7%, ethanol 8%.

[0039] Preparation:

[0040](1) Take raw materials according to the formula ratio;

[0041] (2) Mix fatty alcohol polyoxyethylene ether, sodium dodecyl sulfonate, disodium ethylenediamine tetraacetate, sodium carbonate and cross-linked sodium carboxymethyl cellulose, and stir evenly to obtain mixture A;

[0042] (3) Add polyethylene glycol 4000 into ethanol, stir until completely dissolved, and obtain solution B;

[0043] (4) Add solution B to mixture A and stir evenly to obtain mixture C;

[0044] (5) drying the mixture C at a temperature of 40° C. to obtain a dry solid D;

[0045] (6) Pulverize the dried solid D and pass through a 70-mesh sieve to obtain solid particles;

[0046] (7) Mix the solid...

Embodiment 2

[0049] Raw material formula: alkyl polyglucoside 6%, sodium fatty acid methyl ester sulfonate 25%, 4A zeolite 10%, polyethylene glycol 15001%, tartaric acid 20%, sodium bicarbonate 30%, cross-linked polyvinylpyrrolidone 1%, Polyethylene glycol 60002%, isopropanol 5%.

[0050] The preparation method is as follows:

[0051] (1) Take raw materials according to the formula ratio;

[0052] (2) Mix alkyl polyglucoside, sodium fatty acid methyl ester sulfonate, 4A zeolite, sodium bicarbonate and cross-linked polyvinylpyrrolidone, and stir evenly to obtain mixture A;

[0053] (3) Add polyethylene glycol 6000 into isopropanol, stir until completely dissolved, and obtain solution B;

[0054] (4) Add solution B to mixture A and stir evenly to obtain mixture C;

[0055] (5) drying the mixture C at a temperature of 40° C. to obtain a dry solid D;

[0056] (6) Pulverize the dried solid D and pass through a 70-mesh sieve to obtain solid particles;

[0057] (7) Mix the solid particles ob...

Embodiment 3

[0060] Raw materials: fatty acid methyl ester polyoxyethylene ether 5%, sodium lauryl sulfate 30%, layered sodium silicate 5%, microcrystalline cellulose 2%, citric acid 20%, sodium bicarbonate 30%, carboxymethyl Sodium starch 1.5%, polyvinyl alcohol 17881.5%, n-butanol 5%.

[0061] The preparation method is as follows:

[0062] (1) Take raw materials according to the formula ratio;

[0063] (2) Mix fatty acid methyl ester polyoxyethylene ether, sodium lauryl sulfate, layered sodium silicate, sodium bicarbonate and sodium carboxymethyl starch, and stir evenly to obtain mixture A;

[0064] (3) Add polyvinyl alcohol 1788 into n-butanol, stir until completely dissolved, and obtain solution B;

[0065] (4) Add solution B to mixture A and stir evenly to obtain mixture C;

[0066] (5) drying the mixture C at a temperature of 40° C. to obtain a dry solid D;

[0067] (6) Pulverize the dried solid D and pass through a 70-mesh sieve to obtain solid particles;

[0068] (7) Mix the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com