Oil-resistant environment-friendly fiber-modified nano architectural substrate and preparation method thereof

A technology for fiber modification and building base material, applied in the field of air purification, can solve the problems of environmental pollution and difficult diffusion of pollutants, and achieve the effects of reducing casting cost, improving thermal aging cracking resistance and good thixotropy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

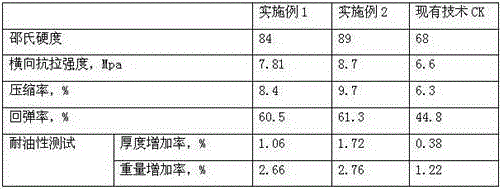

Examples

Embodiment 1

[0019] The present invention also provides a kind of preparation method of oil-resistant environmental protection fiber modified nano-building base material, is made up of the following steps:

[0020] 1) Grinding activated carbon with montmorillonite, nano-titanium dioxide, silicon dioxide, and γ-aminopropyltriethoxysilane, passing through a 100-mesh sieve to obtain mixture A;

[0021] 2) After pulverizing and mixing hydroxypropyl methylcellulose, metal cationic flocculant, nickel nitrate, polyaluminum chloride iron Raney nickel and manganese oxide, add 10 times the mass of distilled water, and then ultrasonically treat it. The ultrasonic treatment conditions are: temperature 90-100°C, ultrasonic power 500W, ultrasonic time 40-50min; mixture B is obtained;

[0022] 3) After pulverizing and mixing the remaining components, add distilled water 8 times the mass, and then perform ultrasonic treatment on it. The ultrasonic treatment conditions are: temperature 70-80°C, ultrasoni...

Embodiment 2

[0026] Embodiment 2 A kind of oil-resistant environmental protection fiber modified nano-building substrate and its preparation method

[0027] An oil-resistant and environmentally friendly fiber-modified nano-building substrate, which consists of raw materials: 60 parts of nitrile rubber, 40 parts of polyurethane rubber, 15 parts of 12-hydroxy methyl stearate, 12 parts of magnesium methacrylate, vinyl 10 parts of trimethylketoxime silane, 25 parts of nylon 66 short fiber, 10 parts of polytrimethylene adipate, 16 parts of diethylene glycol dibenzoate, 20 parts by weight of polylactic chitosan, 15 parts by weight of nano-graphene Parts, 8 parts of pitch-based carbon fiber powder, 7 parts of non-halogenated organic phosphinate, 10 parts of hexamethylenetetramine, 4 parts of trimethylpentyltriethoxysilane, 0.5 parts by weight of conductive mica powder, nano-conductive 0.4 parts by weight of graphite powder, 1 part by weight of trimer of polyisocyanate, 2 parts by weight of polyte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com