Notebook computer shell composite material

A notebook computer and composite material technology, applied in the field of computer shell preparation, can solve the problems of unsatisfactory comprehensive mechanical properties, difficulty in realizing ultra-light and thin design, unsatisfactory thickness and weight of the whole machine, and achieve excellent impact resistance performance, which is conducive to popularization Application, high protection performance and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

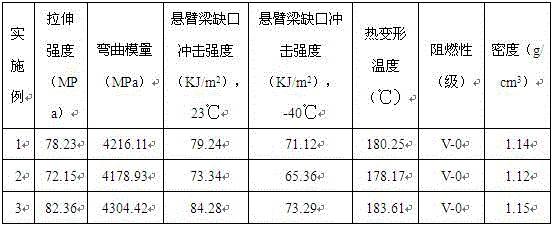

Examples

preparation example Construction

[0057] The preparation method of described notebook computer casing composite material, comprises the following steps:

[0058] S1: Polycarbonate, PBT resin, tributoxyethyl phosphate, tris (2,4-di-tert-butylphenyl) phosphite, dioctyl phthalate, maleic anhydride grafted tertiary Ethylene-propylene rubber is mixed and stirred for 6-12min at a temperature of 764-792°C and a rotational speed of 200-400r / min to obtain a mixture I;

[0059] S2: Under nitrogen protection, add chloropropyl styrene, maleic anhydride grafted polypropylene, hexabromocyclododecane, 3-ethyl-2-butene-1- Alcohol, polypropylene wax, sodium tartrate, sodium polyphosphate, sodium hydroxymethylcellulose, coupling agent, chain extender, compatibilizer, stabilizer, bridging agent, regulator, strengthening agent, coagulant, extender Toughening agent, plasticizer and thickener, stirred for 3.2-5.5 hours at a microwave power of 205-316W, a temperature of 643-708°C, and a rotation speed of 200-400r / min, to obtain a m...

Embodiment 1

[0070] A composite material for a notebook computer casing, which includes the following raw materials in units of weight: 165 parts of polycarbonate, 45 parts of PBT resin, 35 parts of tributoxyethyl phosphate, tris(2,4-di-tert-butylphenyl ) 26 parts of phosphite, 20 parts of dioctyl phthalate, 23 parts of maleic anhydride grafted EPDM rubber, 18 parts of chloropropyl styrene, 15 parts of maleic anhydride grafted polypropylene, hexabromo 13 parts of cyclododecane, 15 parts of 3-ethyl-2-buten-1-ol, 8 parts of aluminum oxide, 7 parts of titanium oxide, 22 parts of polypropylene wax, 16 parts of sodium tartrate, 12 parts of sodium polyphosphate, 15 parts of sodium hydroxymethyl cellulose, 4 parts of nylon 66 fiber, 5 parts of polyphenylene sulfide fiber, 3 parts of glass fiber, 10 parts of talcum powder, 13 parts of calcium carbonate, 1.6 parts of coupling agent, 0.9 parts of chain extender, 2.5 parts of compatibilizer, 1.2 parts of antioxidant, 1.2 parts of stabilizer, 1 part o...

Embodiment 2

[0101]A notebook computer casing composite material, which includes the following raw materials in units of weight: 126 parts of polycarbonate, 38 parts of PBT resin, 32 parts of tributoxyethyl phosphate, tris(2,4-di-tert-butylphenyl ) 22 parts of phosphite, 15 parts of dioctyl phthalate, 19 parts of maleic anhydride grafted EPDM rubber, 14 parts of chloropropyl styrene, 12 parts of maleic anhydride grafted polypropylene, hexabromo 10 parts of cyclododecane, 12 parts of 3-ethyl-2-buten-1-ol, 6 parts of aluminum oxide, 5 parts of titanium oxide, 18 parts of polypropylene wax, 12 parts of sodium tartrate, 8 parts of sodium polyphosphate, 10 parts of sodium hydroxymethyl cellulose, 3 parts of nylon 66 fiber, 4 parts of polyphenylene sulfide fiber, 2 parts of glass fiber, 8 parts of talcum powder, 10 parts of calcium carbonate, 1 part of coupling agent, 0.6 part of chain extender, 2 parts of compatibilizer, 0.9 parts of antioxidant, 0.8 parts of stabilizer, 0.3 parts of toughening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com