Surface-modified magnesium alloy thin-walled tube and its reverse extrusion die and preparation method

A surface modification and reverse extrusion technology, applied in the field of materials, can solve the problems of electrolytic corrosion, allergic reactions and inflammation of the body, increase the economic burden of patients, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

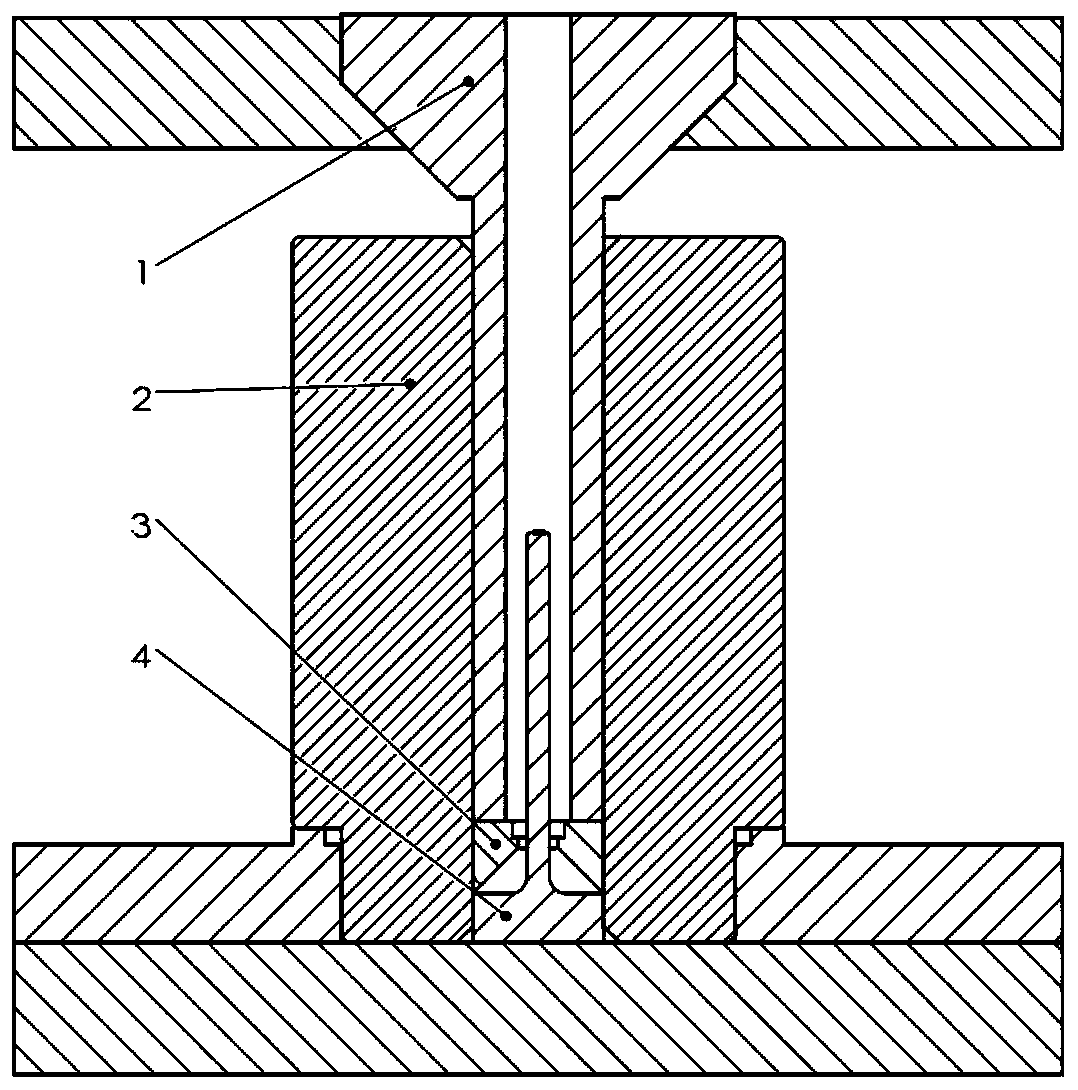

[0039] A reverse extrusion die for a surface-modified magnesium alloy thin-walled tube, such as figure 1 As shown, the composition includes an upper mold part and a lower mold part; the upper mold part includes an upper template 5 and an extrusion rod 1, and the upper template 5 and the extrusion rod 1 are closely combined, and the extrusion rod 1 is a ring structure; The lower mold part includes a lower template 6, an extrusion cylinder 2, an extrusion die 3 and a mandrel 4, an extrusion die 3 is arranged in the extrusion cylinder 2, the extrusion die 3 is a ring structure, and the mandrel 4 wears Over-extrusion die 3, mandrel 4 is connected with lower template 6, extrusion cylinder 2 is connected with lower template 6, the lower part of mandrel 4 is closely combined with extrusion cylinder 2, extrusion rod 1, extrusion cylinder 2 are connected with extrusion The die 3 is coaxial, and the extrusion cylinder 2 is in sliding contact with the extrusion rod 1; the inner diameter ...

Embodiment 2

[0058] The reverse extrusion die of the surface-modified magnesium alloy thin-walled tube is the same as in Example 1.

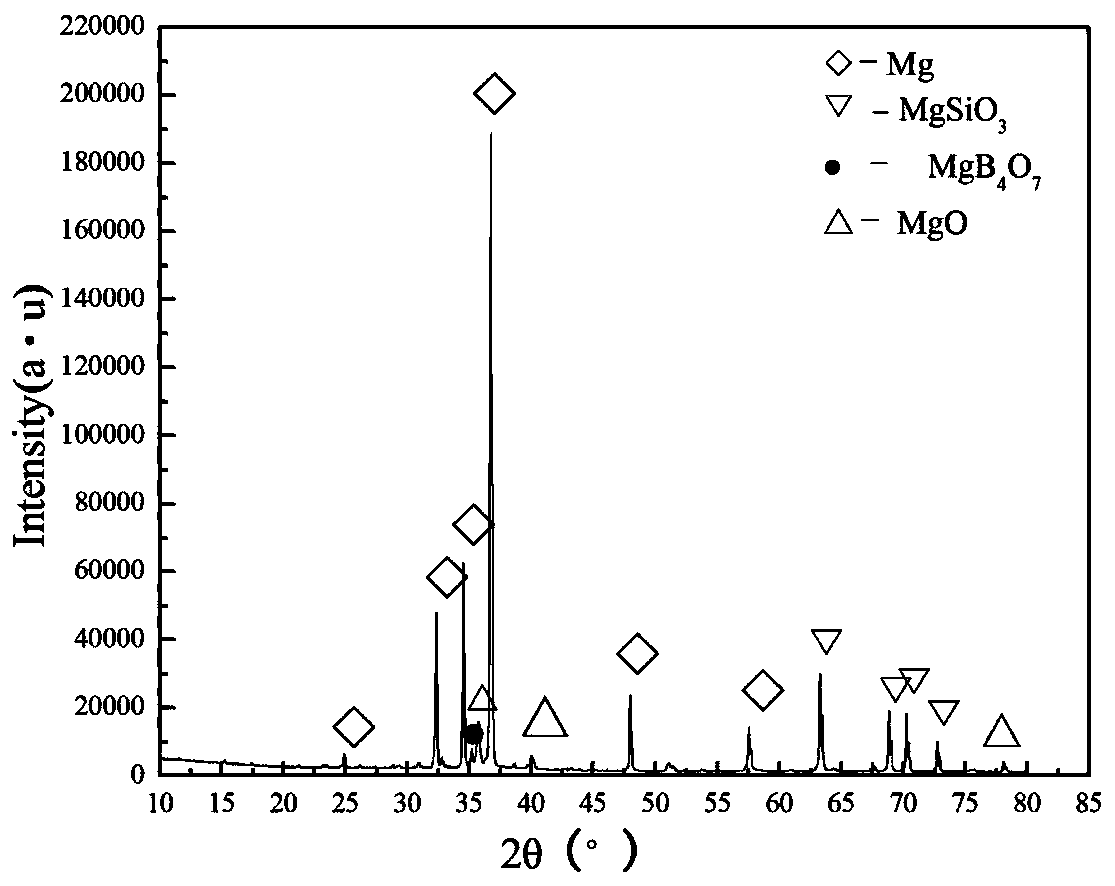

[0059] Using the reverse extrusion die of the surface-modified magnesium alloy thin-walled tube, the surface-modified magnesium alloy thin-walled tube prepared consists of a Mg-Zn-Sr alloy tube and an anodic oxidation surface coating; the Mg- Zn-Sr alloy tube, the composition and mass percentage are: Zn: 6%, Sr: 2%, the balance is Mg, the wall thickness of Mg-Zn-Sr alloy tube is 0.2mm, the outer diameter is 4.0mm; anodized surface The coating is composed of magnesium silicate and magnesium oxide, and the thickness of the surface modification layer is 10-20 μm; wherein, according to the mass ratio, magnesium silicate:magnesium oxide=5:4.

[0060] The method for preparing the surface-modified magnesium alloy thin-walled pipe by adopting a reverse extrusion die of the surface-modified magnesium alloy thin-walled pipe comprises the following steps:

[0061] Ste...

Embodiment 3

[0073] The reverse extrusion die of the surface-modified magnesium alloy thin-walled tube is the same as in Example 1.

[0074] Using the reverse extrusion die of the surface-modified magnesium alloy thin-walled tube, the surface-modified magnesium alloy thin-walled tube prepared consists of a Mg-Zn-Sr alloy tube and an anodic oxidation surface coating; the Mg- Zn-Sr alloy tube, the composition and mass percentage are: Zn: 3%, Sr: 1%, the balance is Mg, the wall thickness of Mg-Zn-Sr alloy tube is 0.4mm, the outer diameter is 5.0mm; anodized surface The coating is composed of magnesium silicate and magnesium oxide, and the thickness of the surface modification layer is 10-20 μm; wherein, according to the mass ratio, magnesium silicate:magnesium oxide=3:2.

[0075] The method for preparing the surface-modified magnesium alloy thin-walled pipe by adopting a reverse extrusion die of the surface-modified magnesium alloy thin-walled pipe comprises the following steps:

[0076] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com