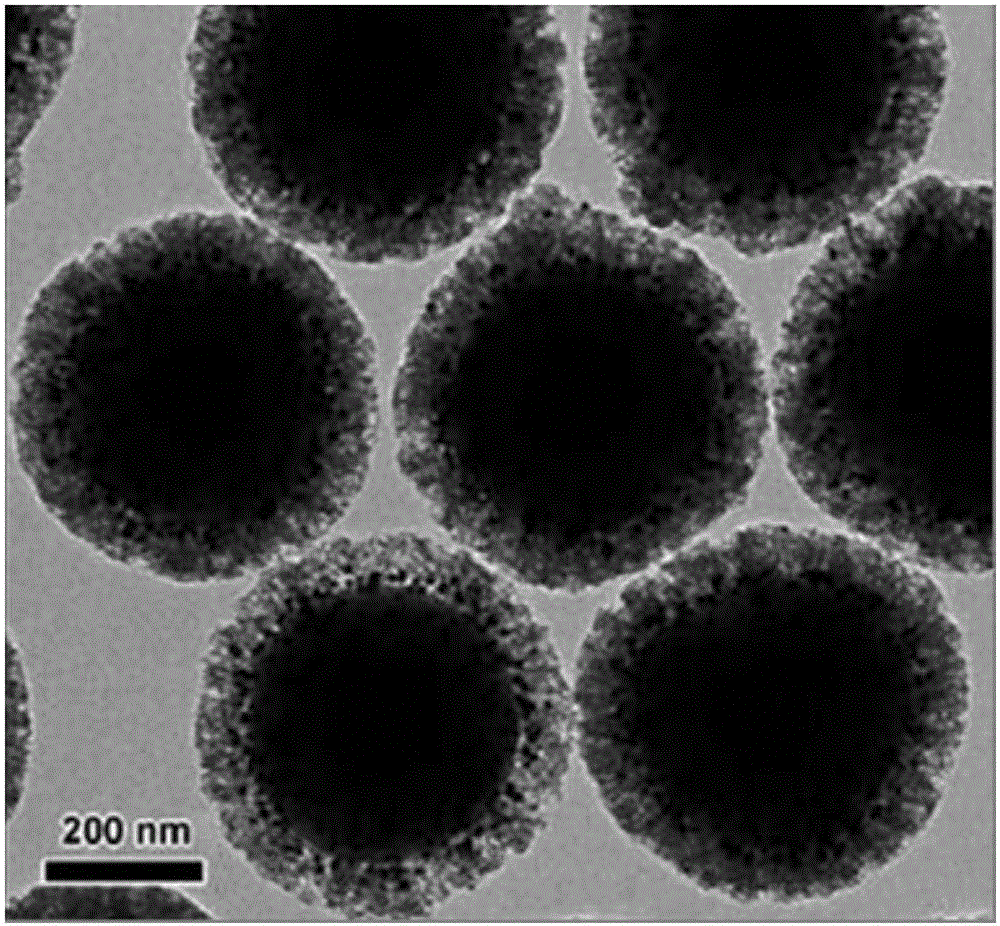

Deoxidating catalyst with core-shell structure, and preparation method and application of deoxidating catalyst

A technology of deoxidation catalyst and core-shell structure, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. High temperature and other problems, to achieve high stability, simple preparation process, large gas treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention provides a method for preparing a deoxidation catalyst with a core-shell structure described in the above technical solution, comprising the following steps:

[0044] (1) Mixing a copper oxide precursor, a cerium oxide precursor, a templating agent and hydrogen peroxide, and performing a hydrothermal reaction to obtain a hydrothermal product;

[0045] (2) mixing the hydrothermal product obtained in the step (1) with a titanium dioxide precursor, and hydrothermally reacting to obtain a deoxidation catalyst precursor;

[0046] (3) Calcining the deoxidation catalyst precursor obtained in the step (2) to obtain a deoxidation catalyst with a core-shell structure.

[0047] In the invention, copper oxide precursor, cerium oxide precursor, template agent and hydrogen peroxide are mixed, and hydrothermal reaction is carried out to obtain a hydrothermal product. In the present invention, the copper oxide precursor is preferably a soluble copper salt, more p...

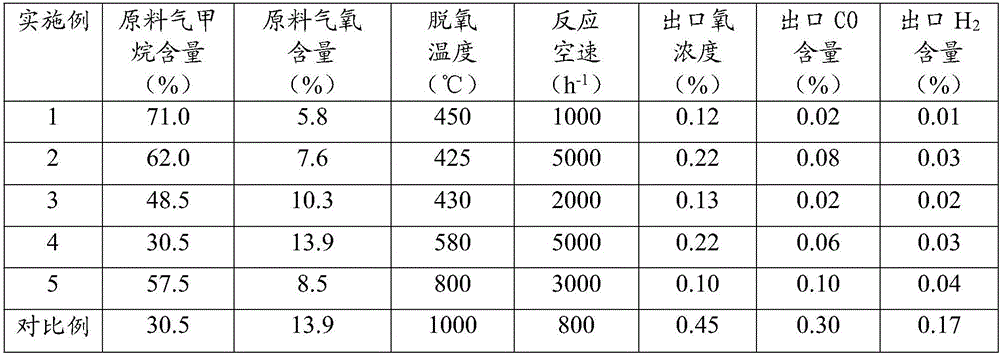

Embodiment 1

[0072] The core part of the core-shell catalyst of the present embodiment is made of 5.0wt% CuO, 20.0wt% CeO 2 Composition, the rest of the mass is the core-shell part of TiO 2 the quality of. Named Catalyst-1.

[0073] The preparation method of this embodiment is:

[0074](1) the copper nitrate ethanolic solution of 50ml molar concentration 0.6mol / L, the cupric chloride copper ethanolic solution of 50ml molar concentration 0.6mol / L and the cerous nitrate ethanolic solution of 370ml molar concentration 3.0mol / L are mixed in proportion, Add 20ml of 0.1mol / L cetyltrimethylammonium bromide aqueous solution and 40ml of 5wt% hydrogen peroxide aqueous solution, stir at 60°C for 8h at 500rpm, and set aside;

[0075] (2) Then add 304g of tetrabutyl titanate ethanol solution dropwise into (1) the above solution, stir evenly at 25°C for 2-6 hours at a high speed of 1000rpm, then put it into a stainless steel reactor, and heat it at 110°C Stir for 6h. Filtration and washing, drying ...

Embodiment 2

[0078] The core part of the core-shell catalyst of the present embodiment is made of 10.0wt% CuO, 10.0wt% CeO 2 Composition, the rest of the mass is the core-shell part of TiO 2 the quality of. Named Catalyst-2.

[0079] The preparation method of this embodiment is:

[0080] (1) Mix 100ml of copper chloride ethanol solution with molar concentration of 0.3mol / L and 70ml of cerous nitrate ethanol solution with molar concentration of 0.2mol / L in proportion, and add 10ml of 0.05mol / L hexadecyltrimethyl bromide Aqueous ammonium chloride solution, 10ml of 0.05mol / L hexamethyleneimine and 30ml of aqueous hydrogen peroxide solution with a mass fraction of 10wt% were stirred at 200rpm at a stirring speed of 60°C for 6h and set aside;

[0081] (2) Then add 81g of tetrabutyl titanate ethanol solution dropwise to (1) above solution, stir evenly at 25°C for 2h at 800rpm high speed, then put it into a stainless steel reaction kettle, stir for 6h under 120°C hydrothermal condition , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com