Sludge treatment method

A kind of sludge treatment and sludge technology, which is applied in biological sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problem of low water removal rate between sludge cells, and avoid The generation of internal colloidal particles, the improvement of dehydration performance, and the effect of cooling and easing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of grinding balls: Mix silicon dioxide, boron oxide, yttrium oxide, magnesium oxide, and boron oxide to obtain a mixed powder; then melt the mixed powder at 1500°C for 1 hour, and quench to obtain a block; crush the block and pass 325-mesh standard sieve to obtain ceramic powder; then mix the ceramic powder with lime and press the ball; finally sinter at 950°C for half an hour and then sinter at 1200°C for 1 hour to obtain the ceramic body; butyl acrylate, N-methylol Acrylamide, styrene and isomeric tridecyl alcohol polyoxyethylene ether are added to water to form an emulsion; then potassium persulfate aqueous solution is added dropwise, and reacted at 70-75°C for 1.5-2 hours to obtain an inert polymer slurry. Disperse the ceramic body in ethanol, then add inert polymer slurry; mix for 2 hours, then add maleic anhydride and diethyl phosphite; continue mixing for 2 hours; then remove the solvent, and then treat at 120-135°C for 20 Minutes, that is, the outer ...

Embodiment 2

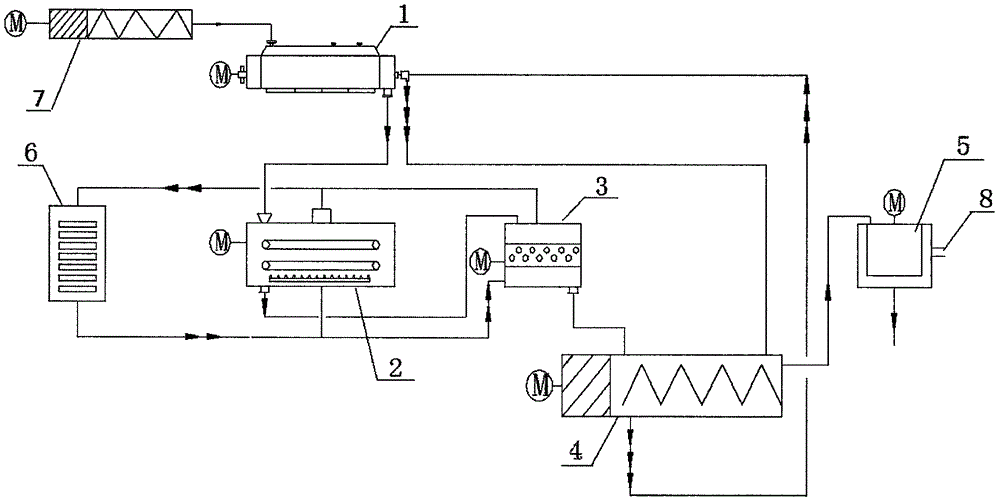

[0028] Using the grinding balls of Example 1 for sludge dewatering: the municipal sludge with a water content of 80% is transported to the sludge cooler by the sludge pump, and the sludge cooler adopts paddle-type cooling equipment to indirect heat exchange. The sludge is cooled and cooled, and the cooling medium comes from the conveying screw. After heat exchange and cooling, the temperature of the sludge drops from normal temperature to 10°C. The sludge cooled from the paddle cooler enters the belt freezer. In the belt freezer, the low-temperature cooling gas enters the freezer from the bottom and directly contacts the sludge, and the temperature of the sludge decreases. As the sludge is conveyed on the belt, the temperature of the sludge is further reduced. According to the different properties of the sludge, the temperature of the sludge is controlled at -5°C when it is discharged from the freezer. As the temperature of the sludge decreases, the structure of the sludge als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com