Preparation method and application of PVA film used for polaroid

A technology of polarizers and graphene quantum dots, applied in the field of polarizers, can solve problems such as blue light leakage of display devices, moisture resistance of polarizing films, thermal performance needs to be improved, and achieve blue leakage prevention, excellent photoelectric characteristics, and good biocompatibility and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

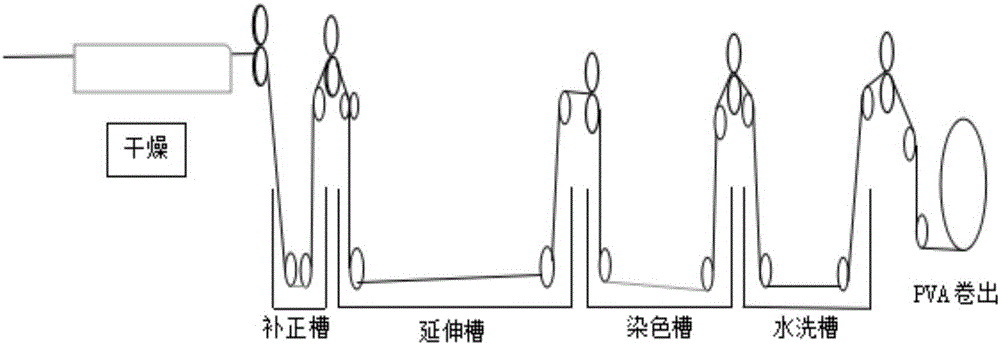

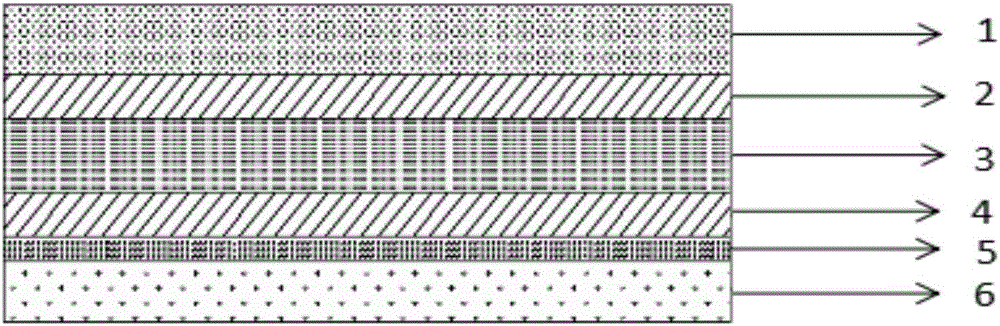

Method used

Image

Examples

Embodiment 1

[0025] Step 1: prepare graphene oxide by Hummers method. Weigh 2g of graphite powder respectively, pour 100ml of concentrated sulfuric acid into it, gradually add 10g of potassium permanganate, and stir at room temperature for 30 minutes. Then adjust the temperature to 35°C, stir at constant temperature for 2 hours, add 150ml of distilled water, wait for the solution to cool down to room temperature, add hydrogen peroxide dropwise until the solution is golden yellow. The resulting solution was filtered with suction, centrifuged and washed until neutral, and then freeze-dried to obtain the desired graphite oxide.

[0026] Step 2: preparing graphene quantum dots. Reduced graphite oxide at high temperature under protective gas to obtain reduced graphene oxide. Weigh 25mg of graphene into a round bottom flask, add 5ml of concentrated sulfuric acid and 15ml of concentrated nitric acid, and ultrasonicate for 10h. Add 250ml of distilled water for dilution, then centrifuge to remov...

Embodiment 2

[0031] Preparation of graphene oxide: ① Mix 50ml of concentrated sulfuric acid, 2g of graphite, and 1g of sodium nitrate in a beaker, slowly add 6g of potassium permanganate under magnetic stirring, and place the reaction in an ice-water bath for 1.5h. ② After the low-temperature reaction is completed, adjust the reaction temperature to 35°C, and stir at a constant temperature for 30 minutes. ④ After the reaction at medium temperature, slowly add 200ml of deionized water dropwise. After the reaction has cooled to room temperature, add hydrogen peroxide until the solution turns golden yellow. ⑤ Add 10% volume of hydrochloric acid, filter with suction, wash away ⑥ After suction filtration, wash the graphite oxide on the filter membrane with distilled water and dilute it in a beaker, then centrifuge to wash the pH to neutral. Freeze-dried for 20 hours to obtain graphite oxide. ⑦Use distilled water as a solvent to dissolve graphite oxide, pour it into a ball mill jar for planet...

Embodiment 3

[0036] Graphene oxide was prepared by traditional Hummers method: reference example 1.

[0037] Preparation of graphene quantum dots: mix 80ml of sulfuric acid and 30ml of nitric acid into a beaker, and place the beaker in an ice bath. Weigh 3g graphene, add graphene in the beaker while stirring, after two hours, weigh 30gNaClO 3 , slowly added to the mixed solution (this process takes 1h), to avoid a sudden sharp rise in temperature and the formation of too much ClO 2 gas. When NaClO 3After complete dissolution, the mixed solution was vigorously stirred at room temperature for 48 h, and the lid of the reaction vessel was loosely closed to facilitate the removal of the generated gas. Thereafter, the mixed liquid was allowed to stand overnight, and the upper two-thirds of the liquid was centrifuged at 5000 rpm for 90 min. , the supernatant was poured into a beaker, and ammonia water was added drop by drop until the pH reached 6-7. Then the resulting solution was put into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com