High-efficiency and environment-friendly type oxa-perfluoropolyether oil field demulsifier and preparation method

A technology of perfluoropolyether and demulsifier, which is applied in the field of petrochemical industry, can solve the problems of complex synthesis method, high raw material requirements, and difficult control of product structure, and achieve the effects of simple preparation method, reduced environmental pollution, and fast dehydration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

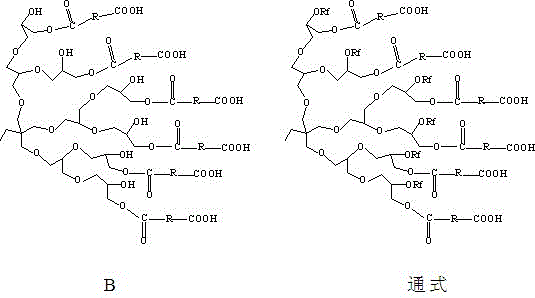

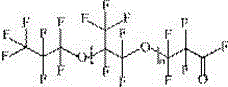

[0055] Take 8 mL of (C) with a constant pressure dropping funnel equipped with tetraethyl dimethyl ether spacer, and slowly add it dropwise into an anhydrous and oxygen-free three-neck flask containing 2.0 g of (A) under stirring at room temperature. The tail gas was collected with saturated potassium carbonate solution. The reaction was continued at room temperature for 2 hours, and the obtained product was air-dried in the air for 24 hours, and then dried in a vacuum oven at 60°C for 24 hours to obtain the demulsifier (D).

[0056] The reaction equation is:

[0057]

[0058]

Embodiment 2

[0060] Take an appropriate amount of 4mL (C) with a constant pressure dropping funnel equipped with a tetraethyl dimethyl ether release agent, and slowly add it dropwise to a four-necked bottle with 6.0 g of (B) under stirring at room temperature. Potassium carbonate solution was collected. The reaction was continued in a constant temperature water bath at 40°C for 2 h, and the obtained product was air-dried in the air for 24 h, and then dried in a vacuum oven at 60°C for 24 h to obtain demulsifier (E).

[0061] Reaction equation:

[0062]

Embodiment 3

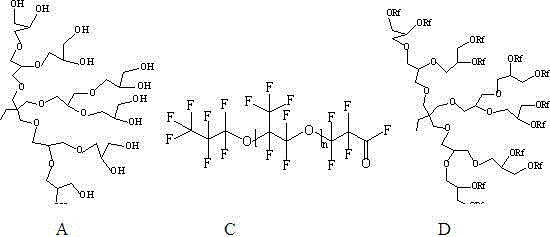

[0064] Accurately weigh 4.4 g of phthalic anhydride into a four-neck flask equipped with a stirrer and pass through nitrogen to remove oxygen, add 20 mL of DMF and heat to 70° C., then add 0.15 g of DMAP dropwise. Accurately weigh 2.0 g (A) and dissolve it in 20 mL DMF solution. After the dissolution is complete, transfer it to the constant pressure dropping funnel, and slowly add it dropwise to the four-necked bottle. Due to the addition of (A), the temperature of the reactor will decrease. The reaction temperature must be controlled to be higher than 70°C, and the reaction needs to be continued for 2 hours until the reaction is complete. After the product is dissolved in methanol, the product is precipitated with ethyl acetate, and vacuum-dried at 60°C for 15 hours to obtain the raw material (F).

[0065] The reaction equation for preparing (F) is basically the same as that of (B), except that phthalic anhydride is used as the carboxyl modifier of (A).

[0066] Take an appro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com