Thioether oxidation method

A technology of sulfide oxidation and tert-butyl hydroperoxide, which is applied in the fields of chemical instruments and methods, organic chemistry, and the preparation of organic compounds, can solve the problem that the anodic oxidation method is not suitable for large-scale implementation, reduces the effective processing capacity of the device, and the environment Pollution and other issues, to achieve the effect of high target oxidation product selectivity, high effective treatment capacity of the device, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

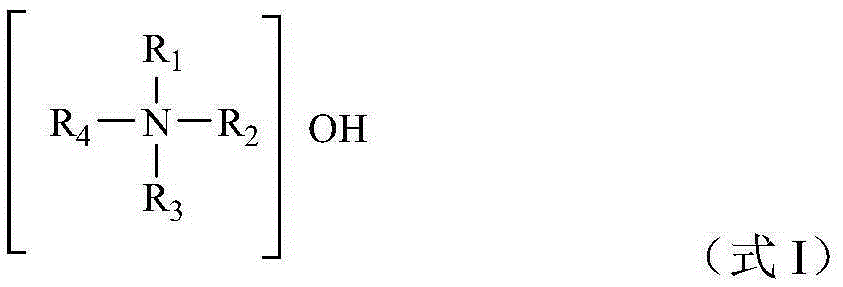

Method used

Image

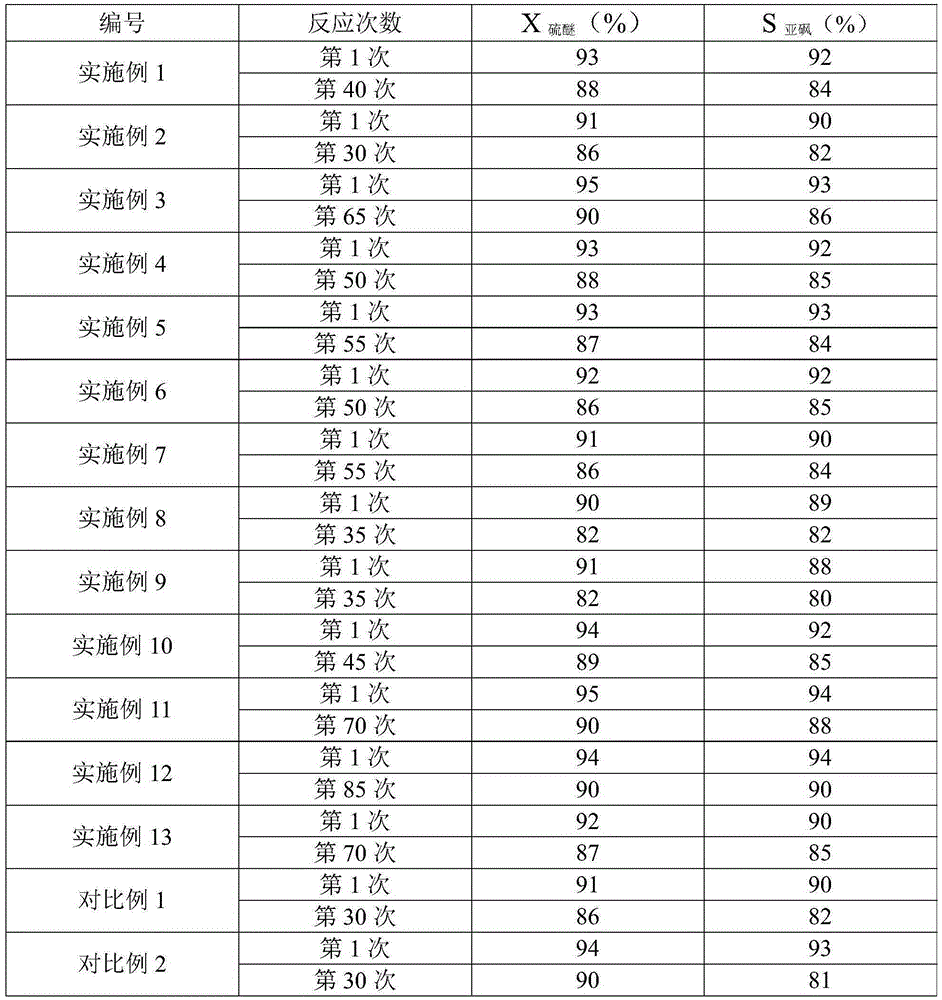

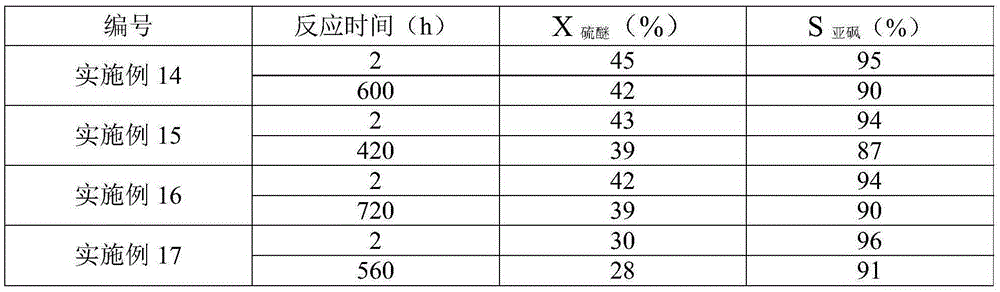

Examples

Embodiment 1

[0093](1-1) Contact reaction between isobutane and oxygen at a temperature of 130°C and a pressure of 2.5 MPa to obtain a reaction mixture containing tert-butyl hydroperoxide, and analyze the composition of the reaction mixture by gas chromatography , Determine the content of tert-butyl hydroperoxide to be 25% by weight. Wherein, the molar ratio of isobutane to oxygen is 1:1; the oxygen is provided in the form of oxygen-containing gas, and in the oxygen-containing gas, the content of oxygen is 80% by volume, and the content of nitrogen is 20% by volume.

[0094] (1-2) Mix the reaction mixture obtained in step (1-1) with hydrochloric acid (HCl concentration is 36.5% by weight) in an autoclave, wherein the reaction mixture obtained in step (1-1) contains tert-butyl The molar ratio of hydrogen oxide to HCl was 1:0.005, the temperature in the autoclave was controlled to 40° C., the pressure in the autoclave was controlled to normal pressure (ie, 1 standard atmosphere), and the mix...

Embodiment 2

[0098] Dimethyl sulfide was oxidized in the same manner as in Example 1, except that step (1-2) was not carried out, and the reaction mixture obtained in step (1-1) was directly sent to step (2). The experimental results are listed in Table 1.

Embodiment 3

[0100] Dimethyl sulfide was oxidized by the same method as in Example 1, except that in step (2), titanium-silicon molecular sieve TS-1 was prepared by the following method.

[0101] Dissolve tetrabutyl titanate in the alkali source template agent tetrapropyl ammonium hydroxide aqueous solution first, then add silica gel (purchased from Qingdao Silica Gel Factory) to obtain a dispersion. In the dispersion, silicon source: titanium source: alkali source Template agent: water molar ratio is 100:4:12:400, silicon source is SiO 2 In terms of titanium source as TiO 2 In terms of alkali source template agent in N. Seal the above dispersion in the beaker with a parafilm and let it stand at room temperature (25°C, the same below) for 24h, then stir at 35°C for 2 hours with magnetic stirring to re-disperse it. Transfer the re-dispersed dispersion liquid to a sealed reaction kettle, undergo the first stage of crystallization at 140°C for 6h, then cool the mixture down to 30°C and expe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com