Genetically engineered bacterium used for combined production of succinic acid and isoprene, and construction method thereof

A technology of genetically engineered bacteria and isoprene, applied in the field of genetic engineering, can solve the problem of no co-production of isoprene and succinic acid, etc., and achieve the effects of improving the total yield and being easy to separate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

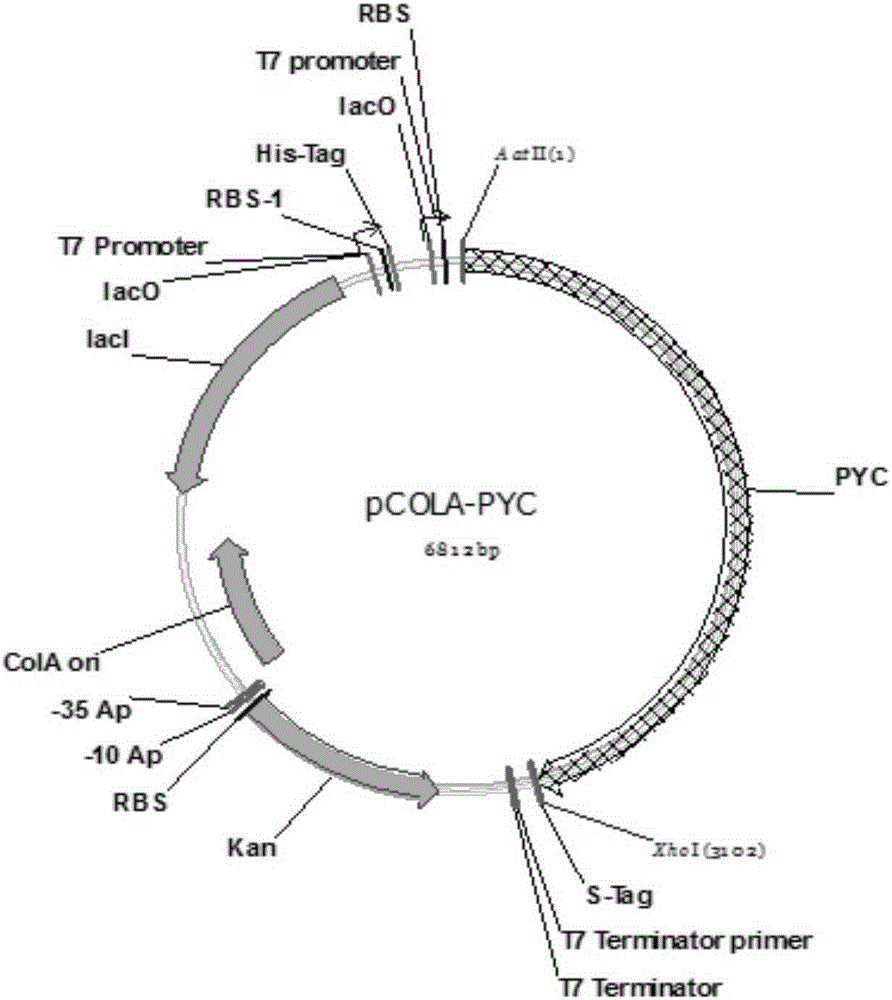

[0038] (1) Cloning and expression of pyruvate carboxylase gene

[0039] Using the genome of Bacillus subtilis (Bacillus subtilis subsp.subtilis str.168, NC_000964.3) as a template, the gene fragment was amplified, and the restriction sites AatⅡ and XhoI were connected at the same time. Take PYC-F-AatⅡ: 5’-ATCG GACGTC ATGTTTGGTGACAAGGTAAAAG-3’

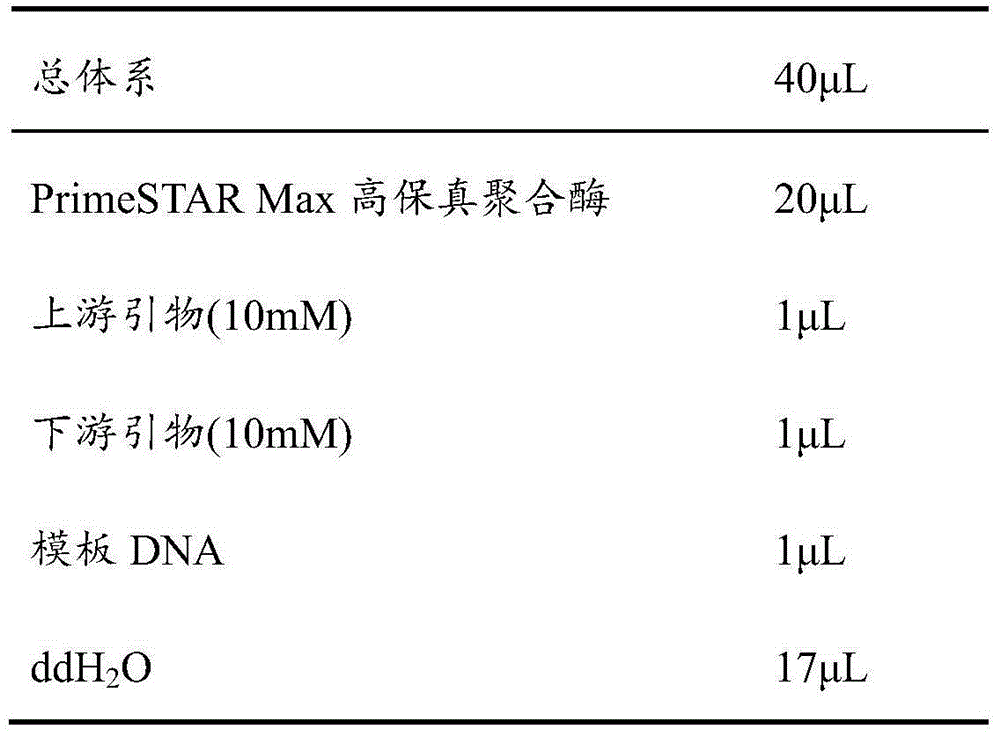

[0040] PYC-R-XhoI:5’-CCG CTCGAG TTATGCTTTTTCAATTTCAAGG-3' was used as a primer, and Bacillus subtilis DNA was used as a template for amplification. The amplification system is shown in Table 1:

[0041] Table 1 PCR amplification system

[0042]

[0043] PCR amplification program: 95°C pre-denaturation for 5min; 95°C denaturation for 30s, 53°C annealing for 30s, 72°C extension for 2min, 35 cycles; 72°C extension for 10min. After the PCR product was purified, it was double digested with endonucleases AatⅡ and XhoI, and then ligated to the pCOLADUet-1 vector that was also double digested to form plasmid pLWPYC1.

[0044] The ligation product w...

Embodiment 2

[0055] (1) Construction of E.coli recombinant strain

[0056] The codon optimized isoprene synthase gene ispS (GenBankaccession No.HQ684728) derived from poplar (Populus nigra) and 1-deoxy-D-xylulose derived from Bacillus subtilis The 5-phosphate synthase gene dxs (Gene ID: 938609) and the 1-deoxy-D-xylulose-5-phosphate reductoisomerase gene dxr (GeneID: 939636) were linked to the plasmid pACYCDuet-1 to construct a plasmid pAdxs2 / dxr2 / ispS, the specific connection method is included in the literature (Applied Microbiology and Biotechnology (2011) 90:1915–1922). The plasmid pAdxs2 / dxr2 / ispS was transformed into E.coli BL21(DE3) cells to construct an engineered strain ZYR4 containing MEP pathway. Prepare ZYR4 into competent cells, then transfer plasmid pLWPYC1 into competent cells, spread on LB solid plates with chloramphenicol and kanamycin, and obtain positive clones by PCR screening, thereby obtaining engineered E. coli LWPYC2 . The engineered strain ZYR4 was used as the cont...

Embodiment 3

[0063] M9 seed medium ( / L): 20g glucose, 6g Na 2 HPO 4 , 3g KH 2 PO 4 , 1g NH 4 Cl, 0.5gNaCl, 0.24g MgSO 4 , 121 ℃ high pressure steam sterilization 15min.

[0064] Fermentation medium ( / 2L): 19.6g K 2 HPO 4 ·3H 2 O, 4.2g citric acid·H 2 O, 0.6g ferric ammonium citrate, 0.8ml concentrated sulfuric acid, 40g glucose, 0.123mg (NH 4 ) 6 Mo 7 O 2 ·4H2O, 0.097mg ZnSO 4 ·7H 2 O, 0.823mg H 3 BO 4 , 0.083mg CuSO 4 ·5H 2 O, 0.527mg MnCl 2 ·4H 2 O, 4ml 1M MgSO 4 , 1900ml distilled water.

[0065] Pick the single clone of strain LWPYC1 into 50ml M9 seed medium and activate it overnight (18-24h) at 37°C and 180rpm. The seeds were inoculated into a 5L small fermentor containing 2L of fermentation medium according to 10% of the inoculum, with aeration volume of 1.3VVM, rotation speed of 400rpm, and cultivation at 37°C to OD 600 At about 20, add IPTG with a final concentration of 0.1-1mM, induce expression at 25°C-37°C, introduce carbon dioxide, adjust the pH with potassium carbonate and potassium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com