Aspergillus tubingensis and application of aspergillus tubingensis in preparing yam diosgenin

A technology of Aspergillus tabin and turmeric saponin, applied in the field of microorganisms, can solve the problems of many intermediate products, single conversion saponin form, long time consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

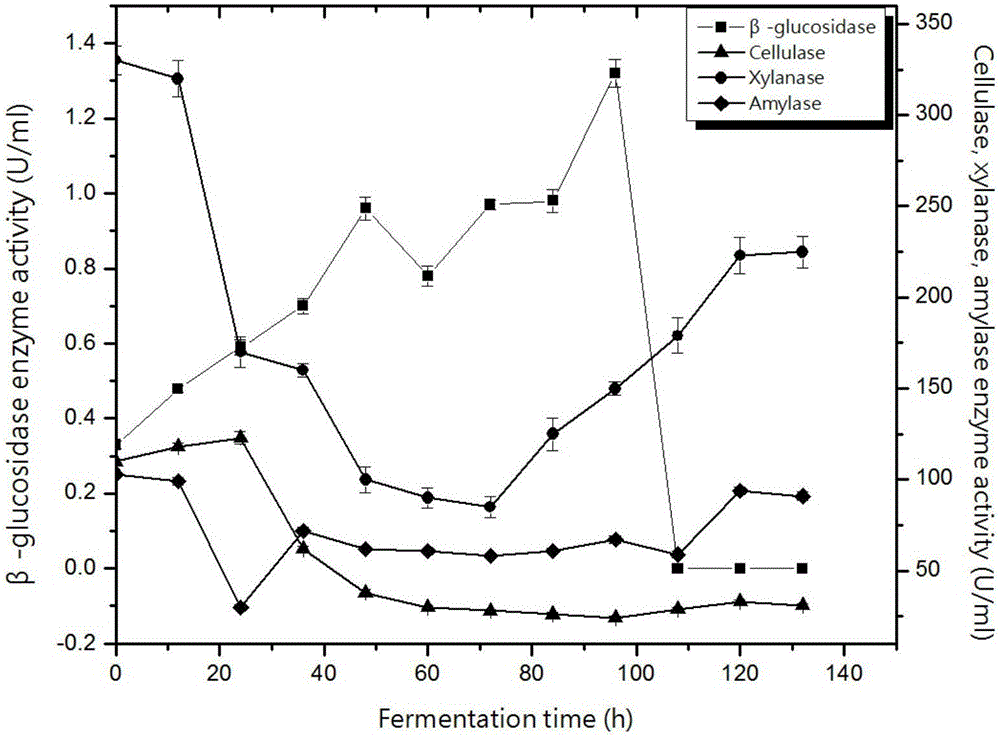

Method used

Image

Examples

Embodiment 1

[0051] Example 1 is a comparative example of preparing saponin by acid-catalyzed hydrolysis conversion of saponin in the aqueous extract of turmeric.

[0052] Take 500g of turmeric dry powder, add water so that the dry weight of turmeric: water = 1:5, mix well, ultrasonicate for 40min, then centrifuge at 8000r / min for 10min, take the supernatant to obtain the turmeric water extract. The water extract of turmeric is subjected to acid-catalyzed hydrolysis, and the hydrolysis conditions are: the acid concentration of the system is 1mol / L, the reaction temperature is 100°C, and the hydrolysis time is 5h; the obtained hydrolyzate is filtered, and the obtained filter cake is washed with tap water or alkaline water until neutral , and then dried to obtain saponin hydrolyzate. The obtained saponin hydrolyzate is extracted with No. 120 gasoline, and the extract is dried to obtain saponin. Gained saponin uses high performance liquid chromatography to carry out quantitative analysis whe...

Embodiment 2

[0054] Example 2 is an example of preparing saponin by converting saponin in turmeric water extract by using the Aspergillus tubingensis fermentation method of the present invention.

[0055] Take 1000g of turmeric dry powder, add water so that the dry weight of turmeric: water = 1:5, mix well, ultrasonically treat for 40min, centrifuge at 8000r / min for 10min, and heat-treat the obtained supernatant at 121°C for 20min to obtain the turmeric water extract .

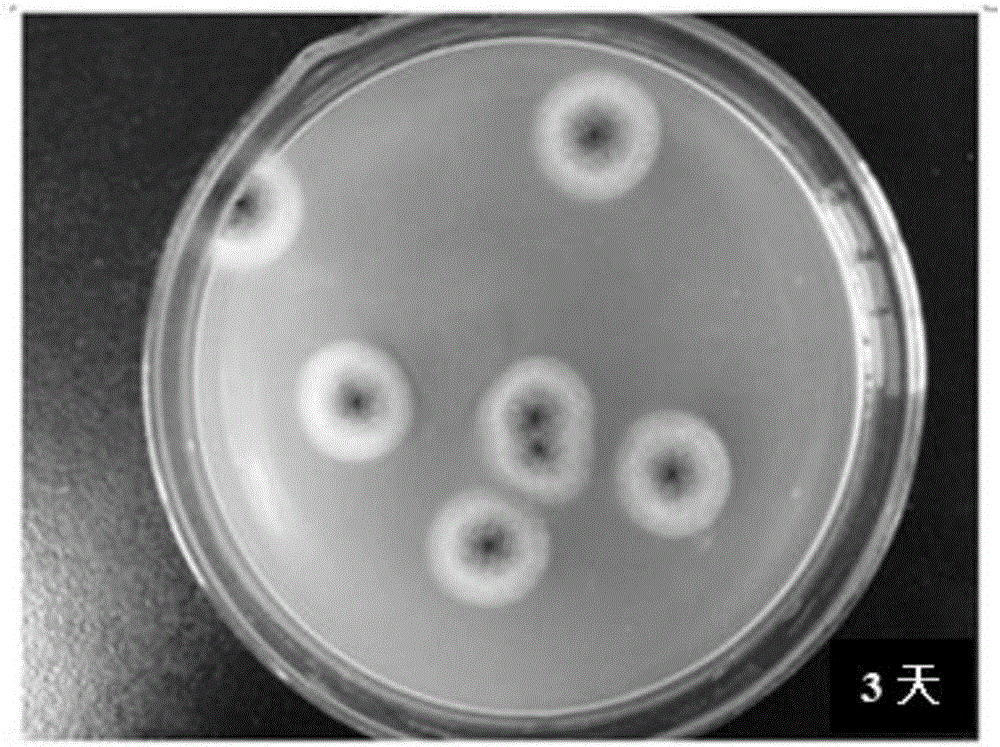

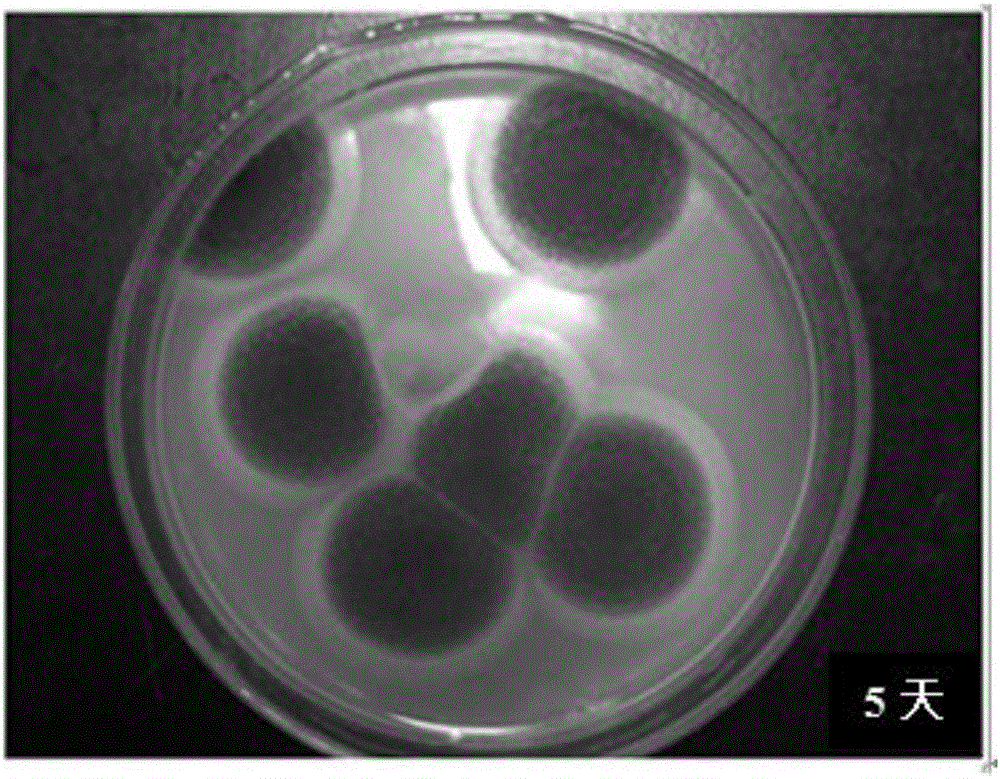

[0056] Transfer Aspergillus tubingensis HG-57 from the slant to PDA solid medium, culture at 28°C for 3 days, after the spores grow, add sterile water with glass beads and shake for 2 minutes to obtain and collect Tabin Aspergillus spore suspension.

[0057] Put the spore suspension of Aspergillus tubingensis into the water extract of turmeric, at 29°C, 210r / min fermentation and culture for 2 days, to obtain the fermentation liquid, and centrifuge the obtained fermentation liquid at 8000r / min for 10min to obtain saponinas...

Embodiment 3

[0059] Example 3 is a comparative example of preparing saponin by acid-catalyzed hydrolysis conversion of saponin in the alcohol extract solution of turmeric.

[0060] Take 2000g of turmeric dry powder, use 75% ethanol to extract the saponin in turmeric, after recovering ethanol, saponin exists in the alcohol extraction extract, add water to be the turmeric alcohol extraction solution, carry out acid-catalyzed hydrolysis to the turmeric alcohol extraction solution, the hydrolysis conditions are: The acid concentration of the system is 1mol / L, the reaction temperature is 100°C, and the hydrolysis time is 5h; the obtained hydrolyzate is filtered, and the obtained filter cake is washed with tap water or alkaline water until neutral, and then dried to obtain saponin hydrolyzate. The obtained saponin hydrolyzate is extracted with No. 120 gasoline, and the extract is dried to obtain saponin. Gained saponin uses high performance liquid chromatography to carry out quantitative analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com